Halogen-free flame retardant hot plastic formed polycarbonate material for high-transparency film and preparation method of material

A transparent film and polycarbonate technology, which is applied in the field of halogen-free flame retardant and hot-molded polycarbonate materials, can solve the problem of poor heat resistance, toughness and appearance of films, mobile phone films cannot be hot-molded, and film transparency is reduced. and other problems to achieve the effect of improving appearance quality, scientific design, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This example provides a preparation method of the halogen-free flame-retardant heat-molding polycarbonate material for highly transparent films of the present invention, specifically:

[0045] Step 1. Prepare materials: dry PC resin, copolymer, phosphorus-containing flame retardant B, silicon-containing flame retardant, anti-dripping agent, and set aside;

[0046] Step 2. Weigh the filler, dry PC resin, copolymer, silicon-containing flame retardant and anti-dripping agent from the formula, and mix them uniformly in a mixer to obtain the first mixture;

[0047] Step 3. Add the first mixture and the phosphorus-containing flame retardant A of the formulation amount, and the phosphorus-containing flame retardant B of the formulation amount after drying into the twin-screw extruder, blend and granulate, wherein, the phosphorus-containing flame retardant B Flame retardant A is injected into the twin-screw extruder through a metering pump, and phosphorus-containing flame retar...

Embodiment 2

[0050] The present embodiment provides the performance testing method of polycarbonate material of the present invention, specifically:

[0051] (1) Determination of glass transition temperature (Tg): refer to the method specified in "Differential Scanning Calorimetry (DSC) for Plastics, Part 2, Glass Transition" (Standard Number: GB / T19466.2-2004) test. The glass transition temperature of polycarbonate material is between 100°C and 120°C before it can be hot-molded.

[0052] (2) Determination of melt mass flow rate (MFR) of plastic thermoplastics: test with reference to the method specified in GB / T3582.1-2018. Among them, under the condition of 300°C and 1.2kg, the film-forming properties can only be achieved when the MFR is 8g / 10min-30g / 10min. If the melt index is high, the film-forming property is poor, and the film forming is also poor; if the melt index is too low, the film-forming property is not good. When the melt mass flow rate is 8g / 10min-30g / 10min, the specific f...

Embodiment 3

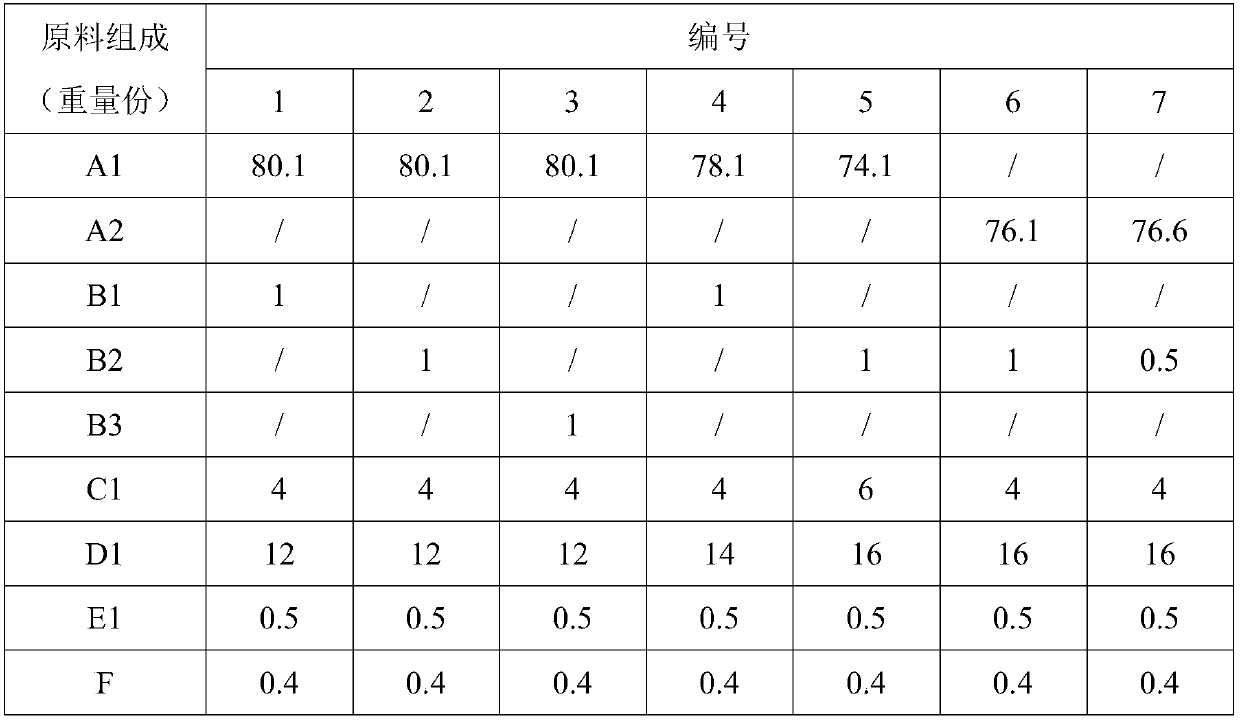

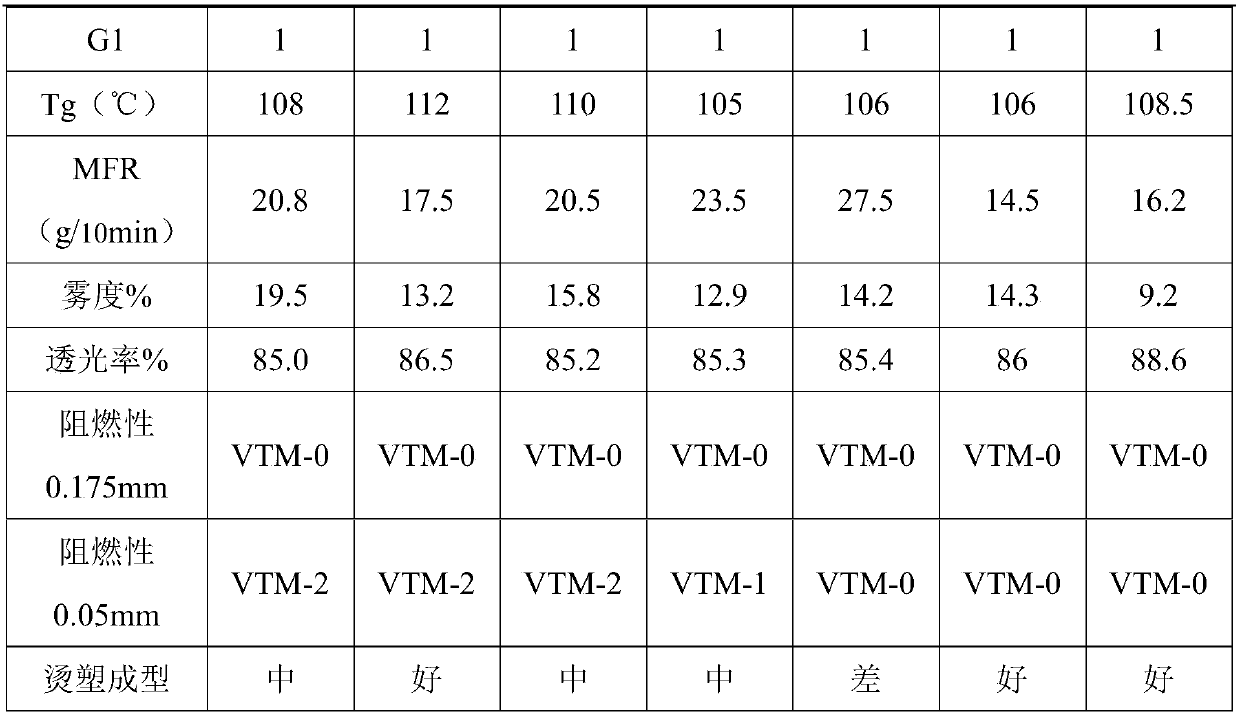

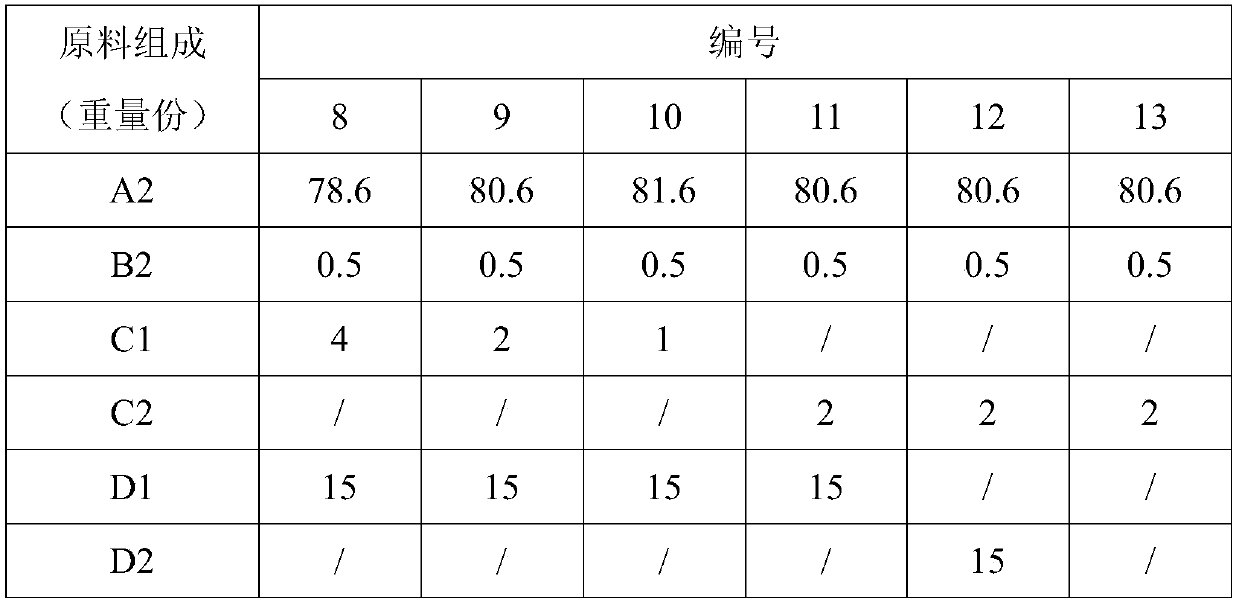

[0059] The raw material composition and the performance of the polycarbonate material of the present embodiment of the present invention are specifically shown in Table 1:

[0060] Table 1

[0061]

[0062]

[0063] As can be seen from Table 1, when the copolymer adopts methyl methacrylate-butadiene-styrene (B2), the light transmittance and hot-molding molding of the obtained polycarbonate material are better than those made by using other two copolymers. Polycarbonate material.

[0064] Flame retardancy: The raw material is 4 parts of m-phenylene tetraphenyl bisphosphate (C1) and 12 parts of polydi(phenoxy)phosphazene (D1). It can reach VTM-0 level, but it can only reach VTM-2 level at 0.05mm. With the increase of the amount of polybis(phenoxy)phosphazene (D1), the flame retardancy increases, and the amount of polybis(phenoxy)phosphazene is 16 parts, and the obtained polycarbonate material film reaches vtm-0 at 0.05mm class.

[0065] Since the MFR of PC 7027 (A2) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com