Silicon-containing organic engine coolant and applications thereof

An engine coolant and organic technology, applied in the chemical industry, can solve the problems of not being able to fully meet the protection requirements of the engine coolant system, insufficient metal protection performance and rubber compatibility, and achieve excellent protection effects, large performance advantages, and good protection The effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

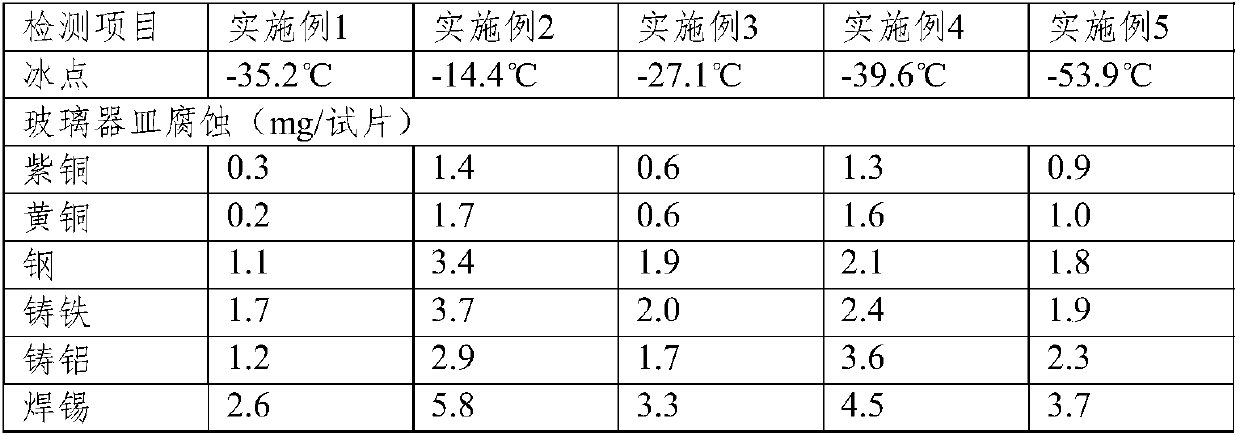

Examples

Embodiment 1

[0029] A silicon-containing organic engine coolant, comprising the following components by weight: 40 parts of ethylene glycol, 8 parts of methylene succinic acid, 3 parts of quaternary ammonium silicate, 3 parts of organosiloxane, polysuccinate 2 parts of imide, 2 parts of amino caprylic acid, 1 part of ε-polylysine, 2 parts of FOAM BAN EC 200, 39 parts of deionized water.

[0030] Preparation method: mix ethylene glycol, methylene succinic acid, quaternary ammonium silicate, organosiloxane, polysuccinimide, amino caprylic acid, ε-polylysine, FOAM BAN EC 200, Ionized water is mixed evenly at room temperature to obtain the product.

Embodiment 2

[0032] A silicon-containing organic type engine coolant, comprising the following components by weight: 25 parts of ethylene glycol, 1 part of methylene succinic acid, 1 part of maleic acid, 2 parts of potassium sodium silicate, organic 2 parts of siloxane, 4 parts of amino caprylic acid, 3 parts of α-amino-β-indolylpropionic acid, 3 parts of α,ε-diaminocaproic acid, 2 parts of sodium dehydroacetate, 0.5 parts of FOAM BAN EC 200, 56.5 parts of deionized water.

[0033] Preparation method: Ethylene glycol, methylene succinic acid, maleic acid, potassium sodium silicate, organosiloxane, amino caprylic acid, α-amino-β-indole propionic acid, α, ε-Diaminocaproic acid, sodium dehydroacetate, FOAM BAN EC 200, and deionized water are mixed uniformly at room temperature to obtain the product.

Embodiment 3

[0035] A silicon-containing organic engine coolant, comprising the following components in parts by weight: 35 parts of ethylene glycol, 10 parts of 2,3-dihydroxysuccinic acid, 5 parts of sodium metasilicate pentahydrate, organosiloxane 5 parts, 0.5 parts of α-amino-β-indolyl propionic acid, 1.5 parts of dimethyl fumarate, 0.8 parts of DSA-5, 42.2 parts of deionized water.

[0036] Preparation method: mix ethylene glycol, 2,3-dihydroxysuccinic acid, sodium metasilicate pentahydrate, organosiloxane, α-amino-β-indolyl propionic acid, dimethyl fumarate according to the above dosage Ester, DSA-5, and deionized water are mixed uniformly at room temperature to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com