Preparation method for antibacterial fibre

A technology of antibacterial fiber and fiber base material, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc. It can solve the problems that fiber raw materials cannot provide long-term and stable antibacterial ability and adverse effects on users' health, and achieve good results. Photochemical stability, simple and easy-to-control production process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

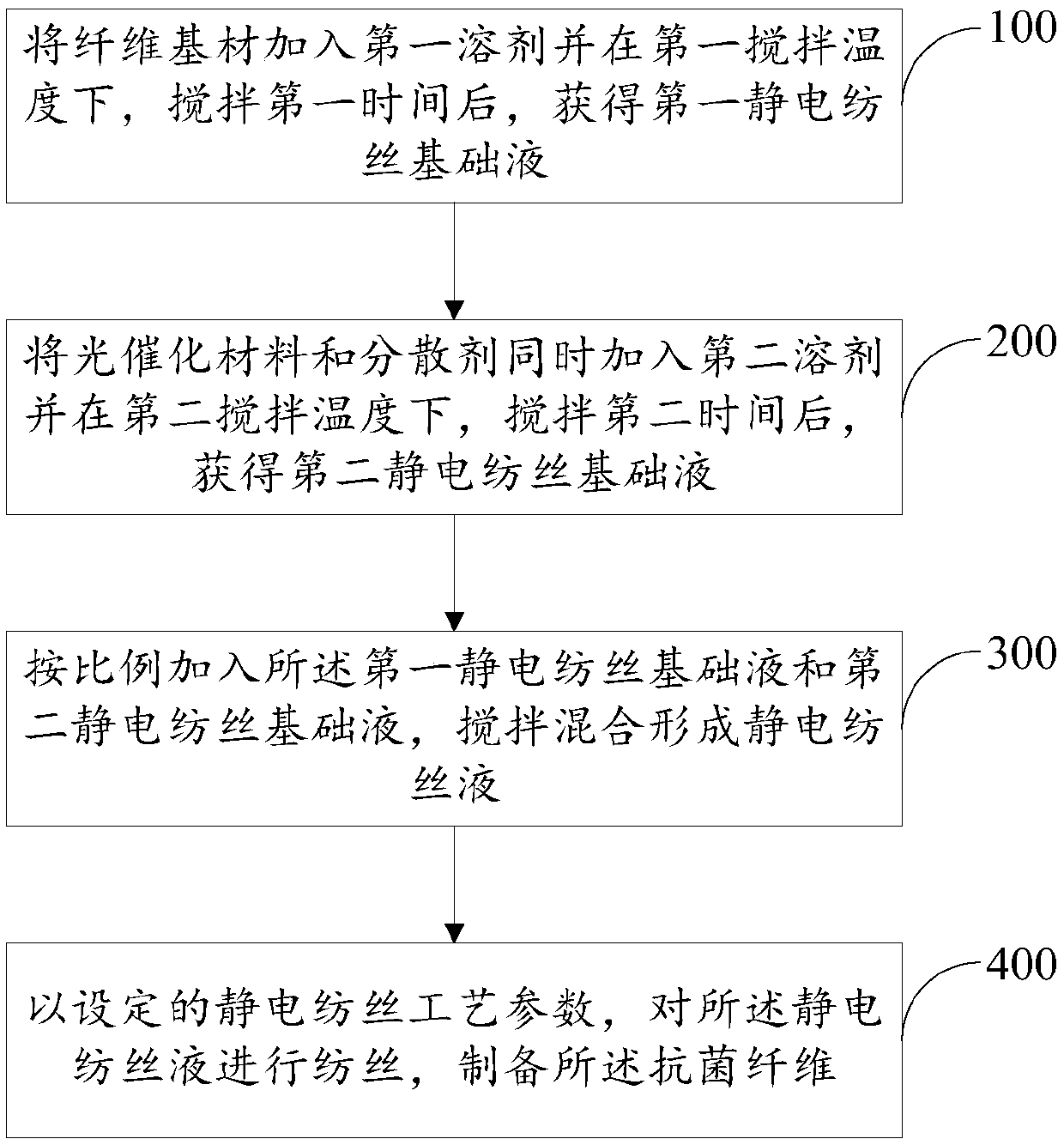

[0033] Such as figure 1 Shown, described preparation method comprises the steps:

[0034] 100. Add the fiber substrate to the first solvent and stir at the first stirring temperature for a first time to obtain a first electrospinning base solution.

[0035] The fiber substrate is the polymer base material that constitutes the antibacterial fiber. Specifically, the corresponding high molecular polymer can be selected and used according to the needs of the actual situation (such as tensile properties, warmth retention or smoothness, etc.). In some embodiments, the fiber substrate is selected from polyacrylonitrile, polylactic acid, polyethylene, polypropylene, polystyrene, polyvinyl alcohol, polyethylene oxide, polycarbonate and polyvinylidene chloride One or more to prepare antibacterial fibers with different performances.

[0036] In some embodiments, the mass percentage of the fiber substrate in the first electrospinning base solution is controlled between 5-25% to avoid i...

Embodiment 1

[0059] 1) Dissolve polyacrylonitrile in an organic solvent mixed with N,N-dimethylformamide (DMF) and acetone (the volume ratio of the two is 1:1), and stir at 50°C for 2 hours to obtain the first An electrospinning base solution.

[0060] Wherein, polyacrylonitrile accounts for 10% by mass of the solution.

[0061] 2) Add the photocatalytic material and dispersant into the acetone solvent, heat to 35°C in a water bath, and stir for 2 hours to obtain the second electrospinning base liquid.

[0062] Wherein, the photocatalytic material is a non-metallic photocatalytic material, accounting for 10% by mass; the dispersant is polyvinylpyrrolidone, accounting for 3% by mass.

[0063] 3) Add the first electrospinning base liquid and the second electrospinning base liquid in proportion, and stir for 1.5 hours to form an electrospinning liquid.

[0064] Wherein, the proportion of the first electrospinning base liquid is 55%.

[0065] 4) Set the parameters of the electrospinning pro...

Embodiment 2

[0069] 1) Dissolving polyvinyl alcohol in water and stirring at 50° C. for 2 hours to obtain the first electrospinning base solution.

[0070] Wherein, polyvinyl alcohol accounts for 20% by mass of the solution.

[0071] 2) Add the photocatalytic material and dispersant into the acetone solvent, heat to 35°C in a water bath, and stir for 1 hour to obtain the second electrospinning base liquid.

[0072] Wherein, the photocatalytic material is titanium dioxide, accounting for 15% by mass; the dispersant is silica airgel, accounting for 3% by mass.

[0073] 3) Add the first electrospinning base liquid and the second electrospinning base liquid in proportion, and stir for 1.5 hours to form an electrospinning liquid.

[0074] Wherein, the proportion of the first electrospinning base liquid is 45%.

[0075] 4) Set the parameters of the electrospinning process, and spin the electrospinning solution to prepare antibacterial fibers.

[0076] Among them, the distance between the posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com