Gas-liquid mixing device and application thereof

A gas-liquid mixing and equipment technology, which is applied in the gas-liquid reaction process and the field of gas-liquid mixing equipment, can solve the problems of increasing the liquid mass transfer area, complex circulation process, long residence time, etc., and achieve the elimination of reaction resistance and large gas carrying capacity , Strong gas-liquid mixing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

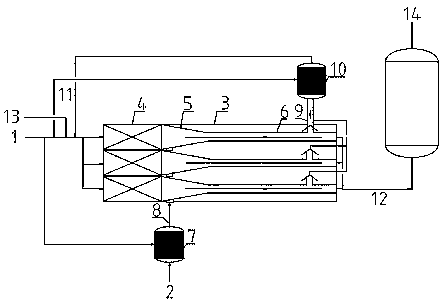

[0059] Adopt attached figure 1 According to the hydrogen dissolving equipment and the hydrogen dissolving process, the preliminary hydrogen dissolving section in the hydrogen dissolving equipment adopts a cylindrical interior filled with a rotary vane spoiler assembly, the residence time is 1.5 minutes, and the low pressure escaped hydrogen is pre-dispersed to 500 nm through the inorganic membrane tube The size of the microbubbles are mixed and dispersed with a small amount of raw material oil and then recycled. The flow rate is 0.045% of the raw material quality; the contraction angle of the accelerated hydrogen dissolving section is 15°, and the length ratio of the accelerated hydrogen dissolving section to the hydrogen releasing section is 1:5; The operating conditions for the introduction position of the hydrogen-rich liquid mixture in the accelerated hydrogen dissolution section are: the temperature is 160° C. and the pressure is 6.0 MPaG. The high-pressure hydrogen disper...

Embodiment 2

[0061] Adopt attached figure 1 In the hydrogen dissolving equipment and the hydrogen dissolving process, the preliminary hydrogen dissolving section in the hydrogen dissolving equipment adopts a static mixer structure, the model is SL-12.5 / 25-6.4-500, the residence time is 1 minute, and the low-pressure hydrogen escapes through the inorganic membrane The tube is pre-dispersed into 500nm-sized micro-bubbles and then mixed and dispersed with a small amount of raw material oil for recycling. The flow rate is 0.03% of the raw material quality; the shrinkage angle of the hydrogen dissolving section is 20°, and the length ratio of the hydrogen dissolving section to the hydrogen releasing section is accelerated It is 1:10; the operating conditions of the introduction position of the hydrogen-rich liquid mixture in the accelerated hydrogen dissolution section are: the temperature is 100°C and the pressure is 5.5 MPaG. The high-pressure hydrogen disperser uses an inorganic membrane tube...

Embodiment 3

[0063] Adopt attached figure 1 In the hydrogen dissolving equipment and the hydrogen dissolving process, the preliminary hydrogen dissolving section in the hydrogen dissolving equipment adopts a cylindrical interior filled with porous plate spoiler components, the residence time is 1.8 minutes, and the low-pressure escaping hydrogen is pre-dispersed by the inorganic membrane tube. The micro-bubbles of 1000nm size are mixed and dispersed with a small amount of raw material oil and then recycled. The flow rate is 0.015% of the raw material quality; the contraction angle of the accelerated hydrogen dissolving section is 25°, and the length ratio of the accelerated hydrogen dissolving section to the hydrogen releasing section is 1:15 ; The operating conditions for the introduction position of the hydrogen-rich liquid mixture in the accelerated hydrogen dissolution section are: the temperature is 280° C. and the pressure is 6.0 MPaG. The high-pressure hydrogen disperser uses an inor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com