Method for preparing bamboo extract and bamboo pulp from bamboos

A technology of extract and bamboo, applied in mechanical equipment, manufacturing tools, textiles and papermaking, etc., can solve the problems of failure to realize industrial engineering production, high material loss rate, high labor intensity, etc., and achieve good development value and promotion prospect , high purity and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

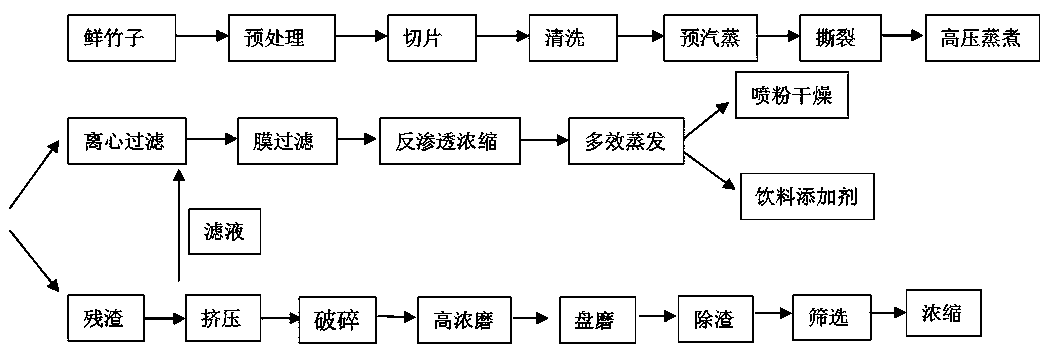

[0029] A method for preparing extract and bamboo pulp from bamboo disclosed in this embodiment specifically includes the following steps:

[0030] (1) Select fresh bamboo with a moisture content of 30%-65%, and impregnate it with a pre-treatment machine to remove mud dust and impurities on the bamboo chips. Bamboo slices are processed by a drum slicer, and the thickness of the bamboo slices is less than 15mm, the width is 5-20mm, and the length is 20-60mm. The sliced bamboo pieces are transported to the washing machine by the conveyor belt, and the impurities in the bamboo are washed with pure water. The cleaned bamboo chips are processed by a screw extrusion and tearing machine, and the bamboo chips are squeezed and torn into bundles and filaments, so that the bamboo extract can be cooked and hydrolyzed at high temperature and high pressure. (2) The bamboo chips obtained after tearing and slicing in the previous step are transported to the high-pressure cooker, the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com