A new type of heat-resistant and flame-retardant foam and its preparation process

A preparation process and heat-resistance technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of being easily ignited by sparks, insufficient resource utilization, and no flame retardancy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

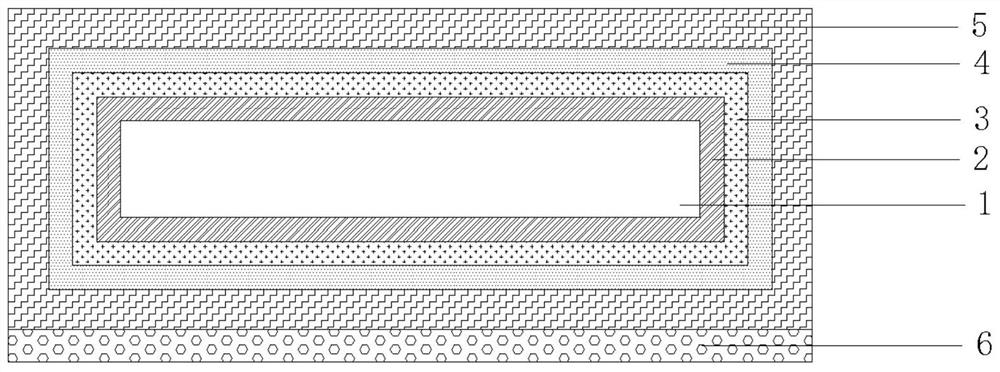

[0097] Such as figure 1 A new type of heat-resistant and flame-retardant foam is shown, including: PET ultra-thin buffer foam layer substrate 1, antibacterial layer 2, moisture-proof layer 3, heat-resistant and flame-retardant layer 4, aluminum foil cloth 5 and embossed release layer Model paper 6; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by an antibacterial layer 2; the outer side of the antibacterial layer 2 is surrounded by a moisture-proof layer 3; the outer side of the moisture-proof layer 3 is surrounded by a heat-resistant flame Layer 4; the outer side of the heat-resistant and flame-retardant layer 4 is surrounded by an aluminum foil cloth 5; one side of the aluminum foil cloth 5 away from the heat-resistant and flame-retardant layer 4 is provided with an embossed release paper 6.

[0098] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0099] Waste foam: 15 p...

Embodiment 2

[0150] Such as figure 1 A new type of heat-resistant and flame-retardant foam is shown, including: PET ultra-thin buffer foam layer substrate 1, antibacterial layer 2, moisture-proof layer 3, heat-resistant and flame-retardant layer 4, aluminum foil cloth 5 and embossed release layer Model paper 6; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by an antibacterial layer 2; the outer side of the antibacterial layer 2 is surrounded by a moisture-proof layer 3; the outer side of the moisture-proof layer 3 is surrounded by a heat-resistant flame Layer 4; the outer side of the heat-resistant and flame-retardant layer 4 is surrounded by an aluminum foil cloth 5; one side of the aluminum foil cloth 5 away from the heat-resistant and flame-retardant layer 4 is provided with an embossed release paper 6.

[0151] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0152] Waste foam: 30 c...

Embodiment 3

[0203] Such as figure 1 A new type of heat-resistant and flame-retardant foam is shown, including: PET ultra-thin buffer foam layer substrate 1, antibacterial layer 2, moisture-proof layer 3, heat-resistant and flame-retardant layer 4, aluminum foil cloth 5 and embossed release layer Model paper 6; the outer side of the PET ultra-thin buffer foam layer substrate 1 is surrounded by an antibacterial layer 2; the outer side of the antibacterial layer 2 is surrounded by a moisture-proof layer 3; the outer side of the moisture-proof layer 3 is surrounded by a heat-resistant flame Layer 4; the outer side of the heat-resistant and flame-retardant layer 4 is surrounded by an aluminum foil cloth 5; one side of the aluminum foil cloth 5 away from the heat-resistant and flame-retardant layer 4 is provided with an embossed release paper 6.

[0204] In addition, the PET ultra-thin cushioning foam layer substrate 1 is formed by the following proportions by weight:

[0205] Waste foam: 22.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com