Method for preparing diphenyl carbonate through phenol ester exchange

A technology of diphenyl carbonate and dimethyl carbonate, which is applied in the field of phenol transesterification to prepare diphenyl carbonate, can solve the problem of low catalyst reactivity, achieve no obvious decline in activity, good technical effect, high reactivity and selectivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

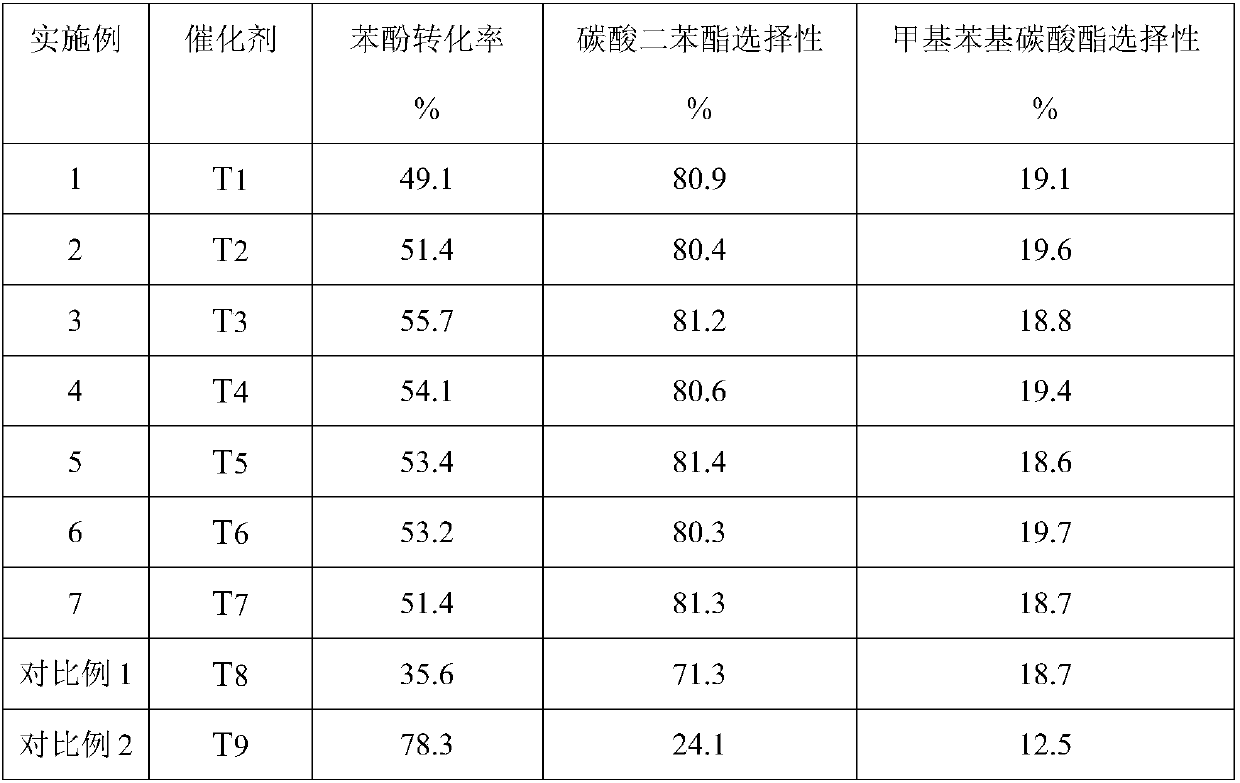

Examples

Embodiment 1

[0031] Take 50ml of tetrabutyl titanate and put it into a dry hydrothermal kettle, add 4ml of HF aqueous solution, seal the reaction kettle and overnight at 160°C for 24h, cool to room temperature, centrifuge, wash 5 times with 0.1M NaOH, and spend overnight at 110°C A sample can be obtained after drying, which is designated as sample T1, and its (001) crystal plane exposure ratio is about 30%.

Embodiment 2

[0033] Take 50ml of tetrabutyl titanate and put it into a dry hydrothermal kettle, add 6ml of HF aqueous solution, seal the reaction kettle and overnight at 160°C for 24h, cool to room temperature, centrifuge, wash 5 times with 0.1M NaOH, and spend overnight at 110°C A sample can be obtained after drying, which is designated as sample T2, and its (001) crystal plane exposure ratio is about 40%.

Embodiment 3

[0035] Take 50ml of tetrabutyl titanate and put it into a dry hydrothermal kettle, add 12ml of HF aqueous solution, seal the reaction kettle and overnight at 160°C for 24h, cool to room temperature, centrifuge, wash 5 times with 0.1M NaOH, and spend overnight at 110°C After drying, a sample can be obtained, which is designated as sample T3, and its (001) crystal plane exposure ratio is about 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com