A kind of preparation method of cefcapene hydrochloride intermediate bcn

A technology of cefcapene hydrochloride and intermediates, applied in organic chemistry and other fields, can solve the problems of long industrial routes and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

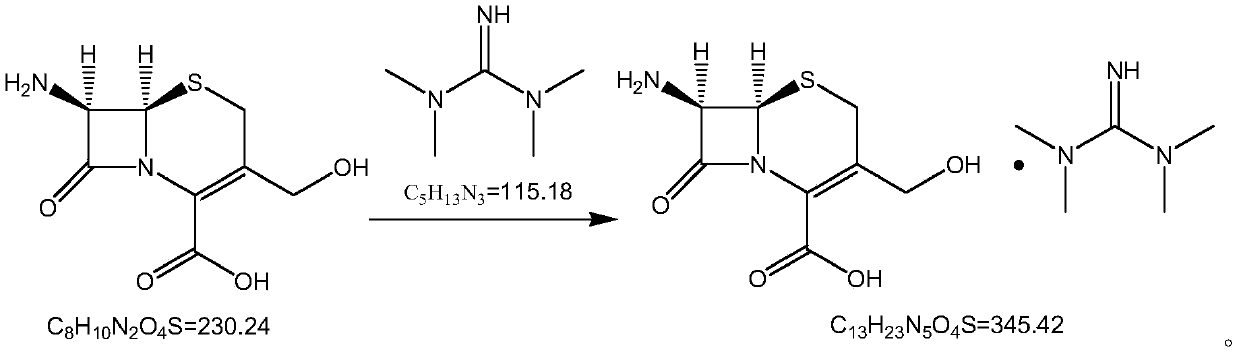

[0023] The invention provides a kind of preparation method of cefcapene hydrochloride intermediate BCN, comprising the following steps:

[0024] In a nitrogen atmosphere, 3-deacetyl-7-aminocephalosporanic acid is mixed with tetramethylguanidine and an organic solvent for a salt-forming reaction to obtain D-7-ACA-MG salt;

[0025] In a nitrogen atmosphere, mix (Z)-2-(2-tert-butoxycarbonylaminothiazol-4-yl)-2-pentenoic acid, mixed anhydride reagent, methylene chloride and amines for mixed anhydride acylation Reaction to obtain mixed anhydride BAPA-MS;

[0026] Mixing the D-7-ACA-MG salt with the mixed anhydride BAPA-MS for condensation reaction to obtain a condensation product;

[0027] The condensation product, chlorosulfonyl isocyanate and dichloromethane are mixed for carbamylation reaction and then hydrolyzed in a mixed solution of ethyl acetate and water to obtain a BCN precursor;

[0028] The BCN precursor is mixed with diisopropylamine for salt formation and crystalliza...

Embodiment 1

[0064] Synthesis of D-7-ACA-MG Salt

[0065] Under the protection of nitrogen, in a dry and clean R0205 reactor, add 400kg of dichloromethane, 45kg of D-7-ACA (3-deacetyl-7-aminocephalosporanic acid), cool down to 5°C, and add dropwise within 30 minutes Tetramethylguanidine 22.5kg, after dripping, stir until dissolved, and the reactor is cooled to -5°C for subsequent use;

[0066] Synthesis of Mixed Anhydride BAPA-MS

[0067] Under nitrogen protection, in a dry and clean R0204 reactor, add 58.3kg of BAPA and 550kg of dichloromethane, start stirring, cool to -15°C, add 22.39kg of methanesulfonyl chloride and 39.56kg of diisopropylamine, and heat up to 0 ℃ heat preservation and stirring for 2 hours, cool down to -25 ℃ for later use;

[0068] condensation reaction

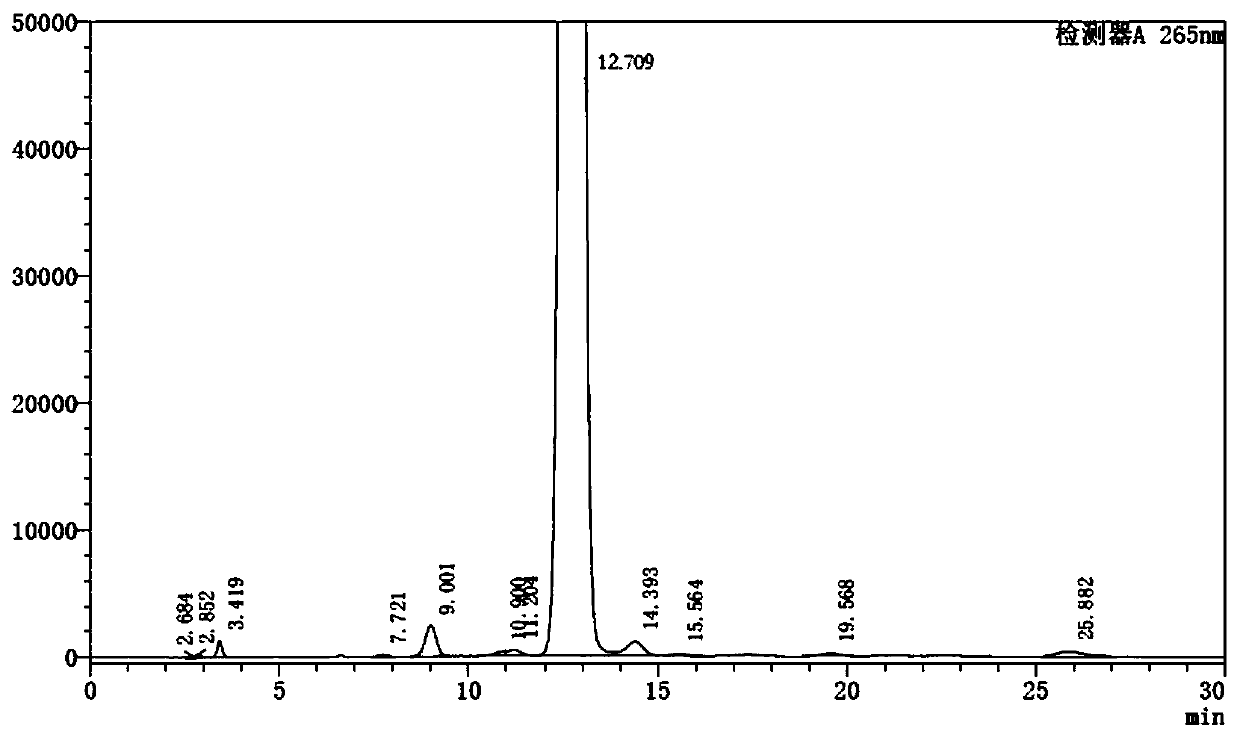

[0069] Quickly press the D-7-ACA-MG salt solution prepared in the R0205 reactor into the R0204 reactor. -MG salt <1.0%, determined by peak area normalization method), after the liquid phase control results come ou...

Embodiment 2

[0085] Synthesis of D-7-ACA-MG Salt

[0086] Under the protection of nitrogen, in a dry and clean R0205 reaction kettle, add 400kg of dichloromethane, 45kg of D-7-ACA (3-deacetyl-7-aminocephalosporanic acid), cool down to 0°C, and add dropwise within 30 minutes Tetramethylguanidine 22.5kg, after dripping, stir until dissolved, and the reactor is cooled to 1°C for subsequent use;

[0087] Synthesis of Mixed Anhydride BAPA-MS

[0088] Under nitrogen protection, in a dry and clean R0204 reactor, add 58.3kg of BAPA and 550kg of dichloromethane, start stirring, cool to 1°C, add 23.57kg of methanesulfonyl chloride and 39.56kg of diisopropylamine, and heat up to 0°C after adding Insulate and stir for 2 hours, cool down to -23°C for later use;

[0089] condensation reaction

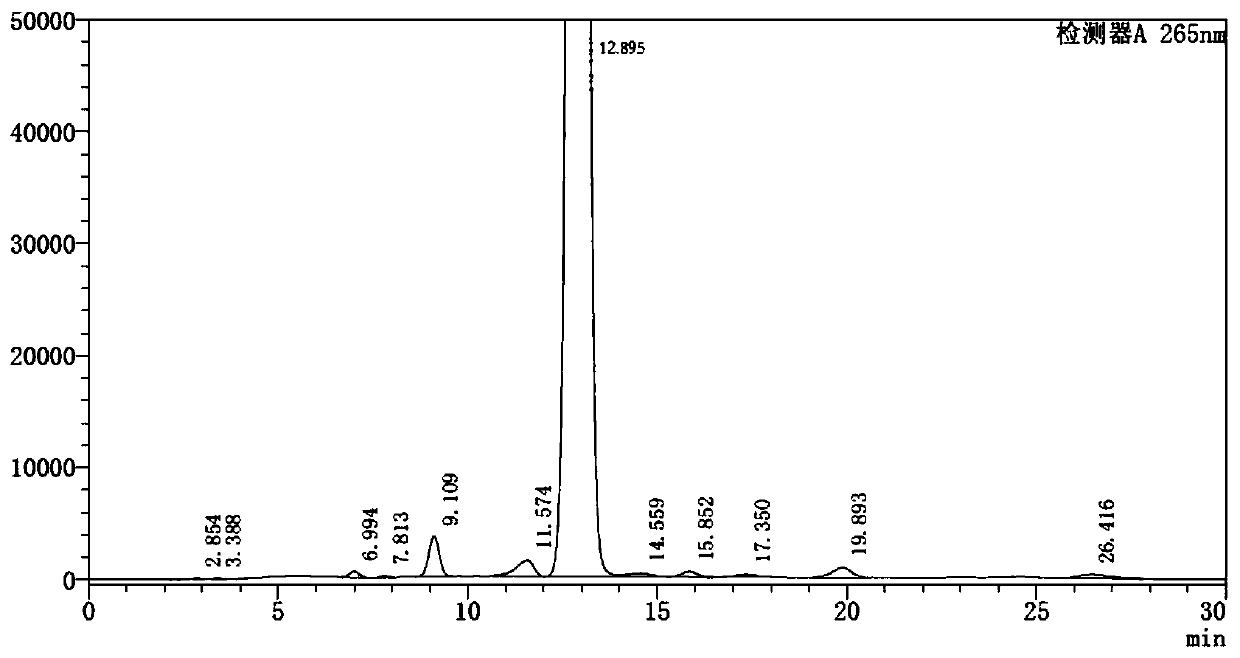

[0090] Quickly press the D-7-ACA-MG salt solution prepared in the R0205 reactor into the R0204 reactor. -MG salt <1.0%, determined by peak area normalization method), after the liquid phase control results co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com