N-CQDs lithium-ion imprinting sensor and preparation method and application thereof

An ion imprinting and sensor technology, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve problems such as complexity and environmental pollution of finished products, and achieve the effects of high conversion rate, simple and feasible operation, and excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

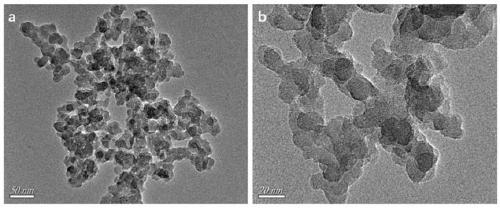

[0025] (1) Weigh 0.525g of CA, dissolve it in 10ml of deionized aqueous solution with pH=13, and stir until completely dissolved. Then, 235 μl of EDA was added dropwise to the solution, sealed, and stirred for 5 minutes. Then pour the above solution into a 30ml polytetrafluoroethylene reactor, set the hydrothermal temperature to 200°C and the time to 8h, and then put it into an oven for reaction. After the reaction was completed, the sample was cooled to room temperature with the furnace, and the sample was dialyzed with a 0.22 μm dialysis membrane for 48 hours. Finally, dry in a vacuum oven at 60°C.

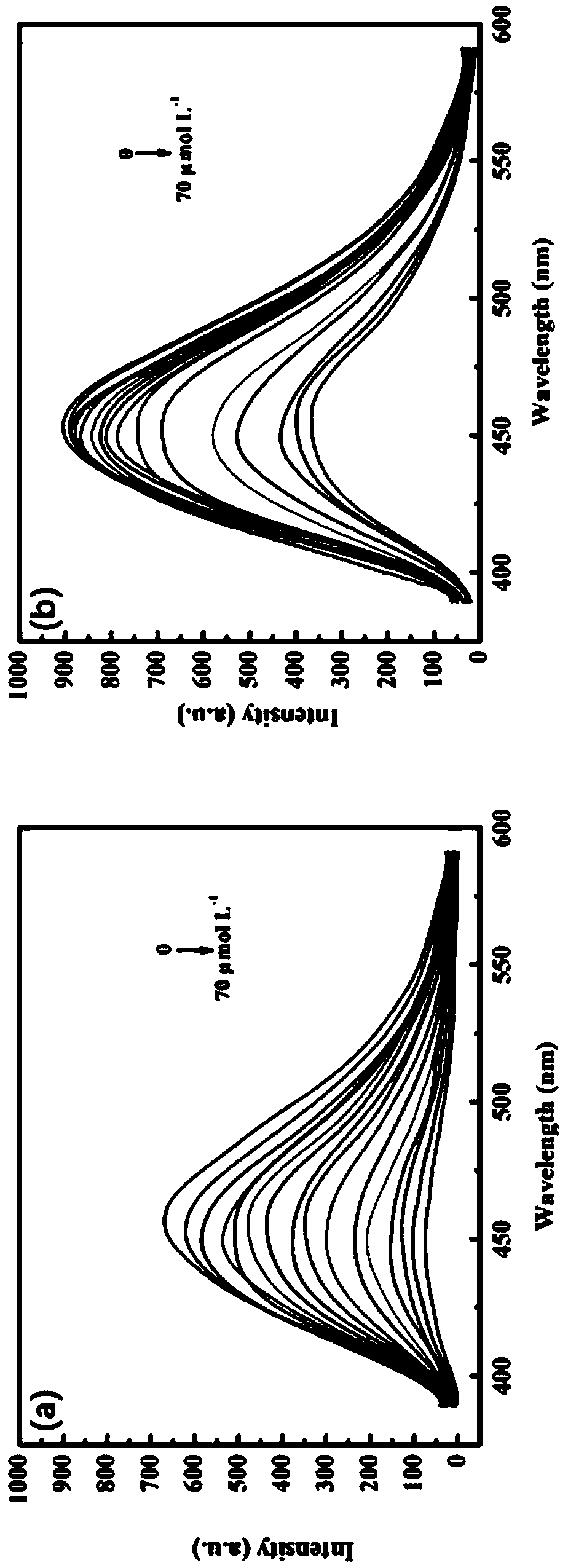

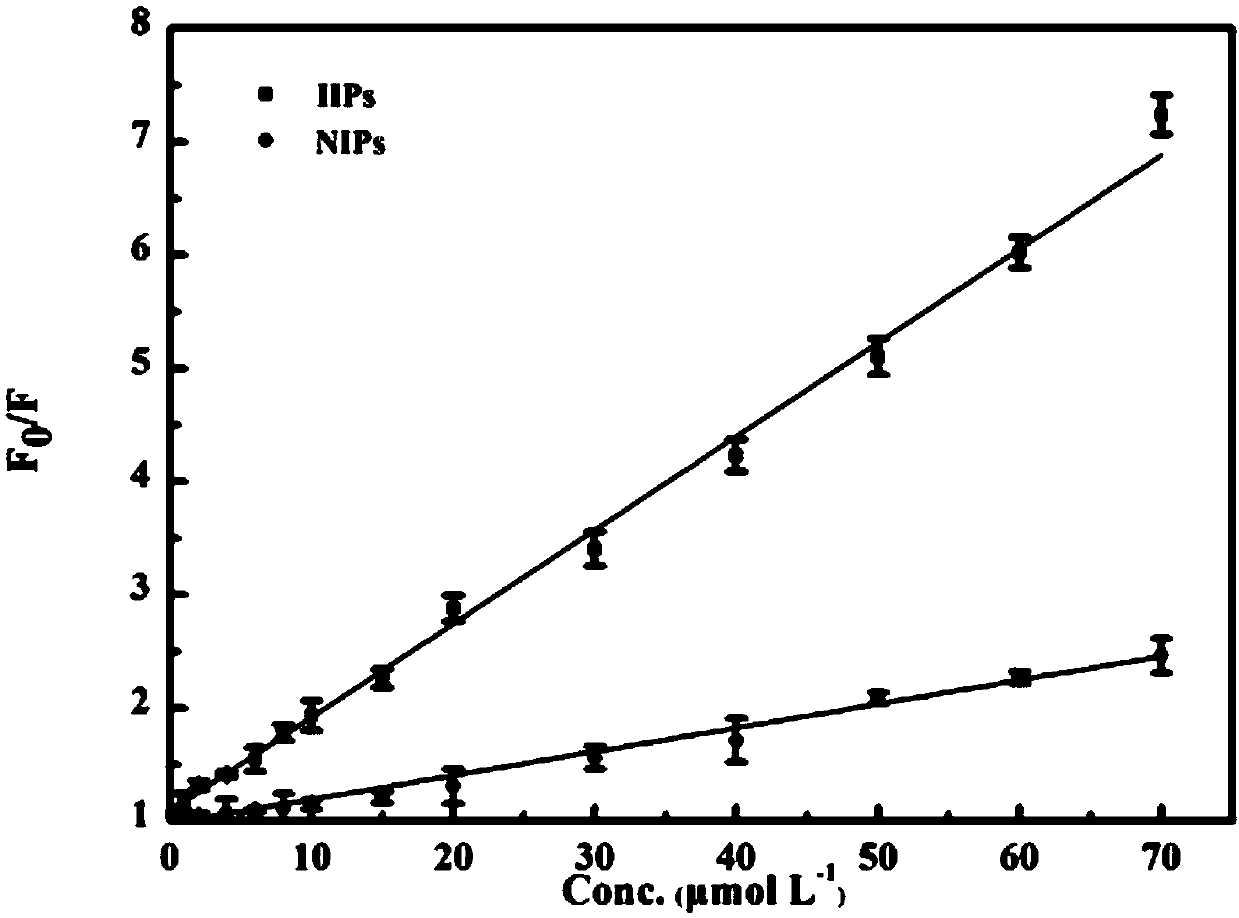

[0026] (2) 0.2mmol B15C5 and 0.2mmol LiNO 3 Added to 15ml of acetonitrile solution, stirring at room temperature for 30min. Then, 1.2mmol methacrylic acid (MAA) was added dropwise to the solution, and stirred at room temperature for 30min to complete MAA and B15C5:Li +self-assembly. Add 45 mg of dry N-CQDs to the above solution and sonicate for 15 min. Subsequently, 4.0 mm...

Embodiment 2

[0028] (1) Weigh 0.525 g of CA, dissolve it in 10 ml of deionized aqueous solution with pH=10, and stir until completely dissolved. Then, 335 μl of EDA was added dropwise to the solution, sealed and stirred for 5 minutes. Then pour the above solution into a 30ml polytetrafluoroethylene reactor, set the hydrothermal temperature to 180°C and the time to 7h, and then put it into an oven for reaction. After the reaction was completed, the sample was cooled to room temperature with the furnace, and the sample was dialyzed with a 0.22 μm dialysis membrane for 48 hours. Finally, dry in a vacuum oven at 60°C.

[0029] (2) 0.2mmol B15C5 and 0.2mmol LiNO 3 Added to 20ml of acetonitrile solution, stirring at room temperature for 30min. Then, 1.2mmol methacrylic acid (MAA) was added dropwise to the solution, and stirred at room temperature for 30min to complete MAA and B15C5:Li + self-assembly. Add 50 mg of dry N-CQDs to the above solution and sonicate for 20 min. Subsequently, 4.5 ...

Embodiment 3

[0031] (1) Weigh 0.525 g of CA, dissolve it in 10 ml of deionized aqueous solution with pH=7, and stir until completely dissolved. Then, 435 μl of EDA was added dropwise to the solution, sealed, and stirred for 5 minutes. Then pour the above solution into a 30ml polytetrafluoroethylene reactor, set the hydrothermal temperature to 150°C and the time to 5h, and then put it into an oven for reaction. After the reaction was completed, the sample was cooled to room temperature with the furnace, and the sample was dialyzed with a 0.22 μm dialysis membrane for 48 hours. Finally, dry in a vacuum oven at 60°C.

[0032] (2) 0.2mmol B15C5 and 0.2mmol LiNO 3 Added to 25ml of acetonitrile solution, stirring at room temperature for 30min. Then, 1.2 mmol methacrylic acid (MAA) was added dropwise to the solution, and stirred at room temperature for 30 min to complete the self-assembly of MAA and B15C5: Li+. Add 55 mg of dry N-CQDs to the above solution and sonicate for 25 min. Subsequent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com