Starch-coated modified calcium carbonate and preparation method thereof

A technology of calcium carbonate and starch, which is applied in the direction of chemical instruments and methods, addition of inorganic compounds, fibrous fillers, etc., can solve the disadvantages of paper tensile properties and tear resistance, the effect of calcium carbonate addition is not obvious, and the increase of calcium carbonate The amount of addition and other issues, to achieve the effect of obvious modification, simple but effective modification method, and improve the retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of preparation method of starch coating modified calcium carbonate, comprises the steps:

[0027] (1) Cornstarch and water are formulated into starch milk, and heavy calcium carbonate is added when stirring;

[0028] (2) Start to heat up after stirring evenly, add epichlorohydrin after heating up to 50°C, then continue to heat up to 80°C, and keep warm for 2 hours to obtain a mixed solution;

[0029] (3) pouring the mixed solution obtained in the step (2) into the ammonium sulfate solution of 30% by mass fraction, after the solid matter precipitates out, collect the solid, dry and grind to obtain this modified calcium carbonate;

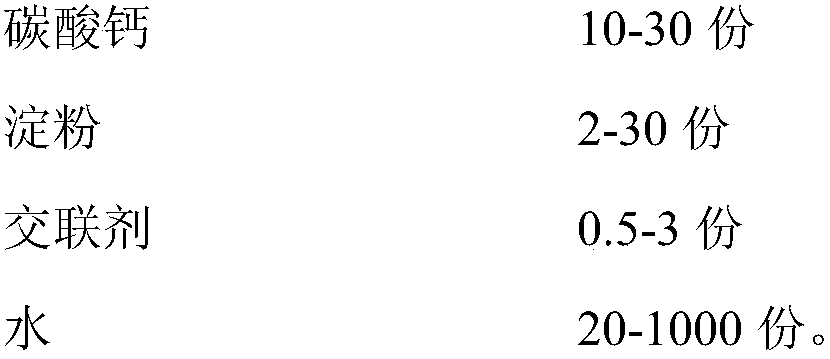

[0030] Wherein, calculated by mass parts, the consumption of each composition is as follows:

[0031]

Embodiment 2

[0033] The present embodiment provides a kind of preparation method of starch coating modified calcium carbonate, comprises the steps:

[0034] (1) Cornstarch and water are formulated into starch milk, and heavy calcium carbonate is added when stirring;

[0035] (2) After stirring evenly, start to heat up, heat up to 60°C, add sodium stearate, then continue to heat up to 85°C, and keep warm for 3 hours to obtain a mixed solution;

[0036] (3) pouring the mixed solution obtained in the step (2) into the ammonium sulfate solution of 30% by mass fraction, after the solid matter precipitates out, collect the solid, dry and grind to obtain this modified calcium carbonate;

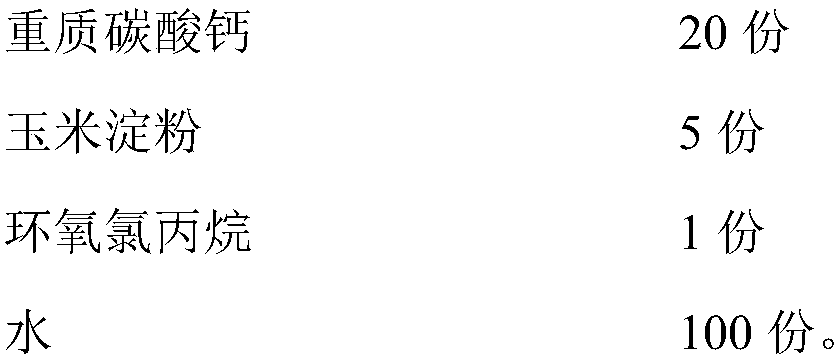

[0037] Wherein, calculated by mass parts, the consumption of each composition is as follows:

[0038]

Embodiment 3

[0040] The present embodiment provides a kind of preparation method of starch coating modified calcium carbonate, comprises the steps:

[0041] (1) Cornstarch and water are formulated into starch milk, and heavy calcium carbonate is added when stirring;

[0042] (2) Start to heat up after stirring evenly, add sodium stearate after the temperature is raised to 60°C, then continue to heat up to 85°C, and keep warm for 3 hours to obtain a mixed solution;

[0043] (3) pouring the mixed solution obtained in the step (2) into the ammonium sulfate solution that the mass fraction is 40%, after the solid matter precipitates out, collect the solid, dry and grind to obtain this modified calcium carbonate;

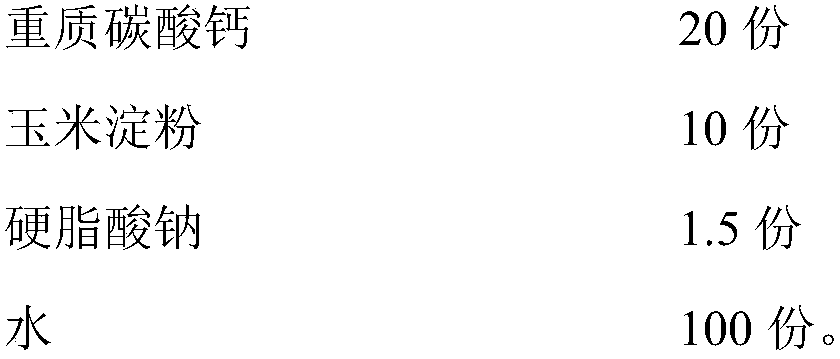

[0044] Wherein, calculated by mass parts, the consumption of each composition is as follows:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com