Normal-temperature air drying type single-component water-based acrylic anticorrosion finish paint

A water-based acrylic, self-drying technology, used in anti-corrosion coatings, coatings, polyether coatings, etc., can solve the problems of slow natural drying, large environmental pollution, large VOC emissions, etc., and achieve less chemical reaction and VOC emissions. Low, water resistance and good outdoor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

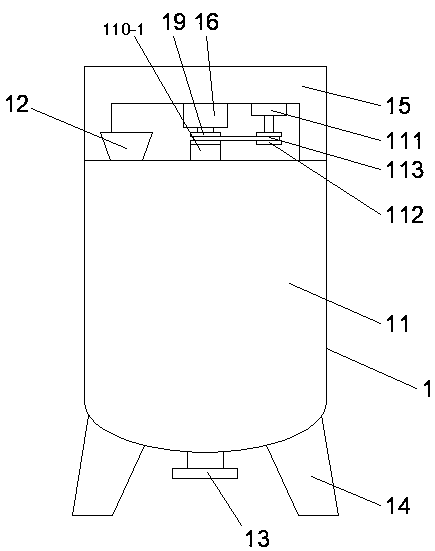

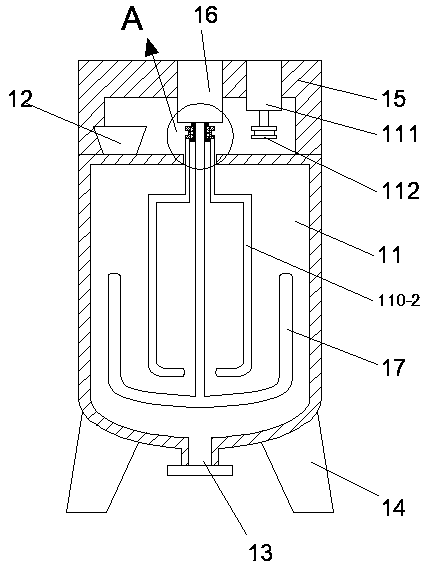

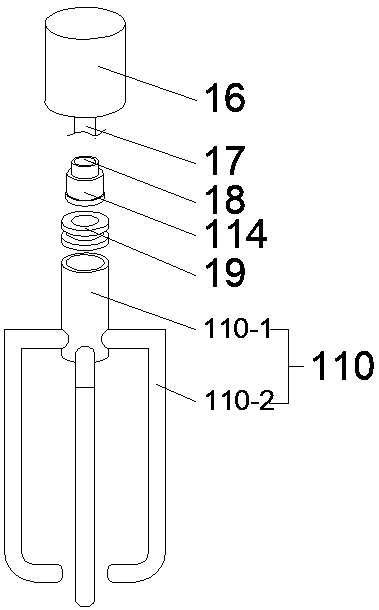

Image

Examples

Embodiment 1

[0040] A kind of preparation method of normal temperature self-drying type one-component waterborne acrylic acid anticorrosion finish paint, it is characterized in that, preparation steps are as follows:

[0041] (1) To prepare a toughening agent, put polyamide and polyurethane into a mixing device in a weight ratio of 3:2 and mix them, and mix them uniformly to obtain a toughening agent;

[0042] (2) Put water-based acrylic resin, dispersant, defoamer, polyethylene glycol dioleate, toughener, lauryl alcohol ester, and deionized water into the paint let-down reactor for reaction and mixing. The mixing time 1H, mixing speed 550r / min; then put mica powder, talc powder, diatomaceous earth, titanium dioxide into the paint let-down reaction kettle and stir and mix, stirring time 1H, stirring speed 750r / min, after stirring evenly, the finished product is obtained.

[0043] The composition includes in parts by weight:

[0044] 30 parts water-based acrylic resin

[0045] Mica powder...

Embodiment 2

[0078] Compared with Embodiment 1, the differences of this embodiment are:

[0079] A kind of preparation method of normal temperature self-drying type one-component waterborne acrylic acid anticorrosion finish paint, it is characterized in that, preparation steps are as follows:

[0080] (1) To prepare a toughening agent, put polyamide and polyurethane into a mixing device in a weight ratio of 3:2 and mix them, and mix them uniformly to obtain a toughening agent;

[0081] (2) Put water-based acrylic resin, dispersant, defoamer, polyethylene glycol dioleate, toughener, lauryl alcohol ester, and deionized water into the paint let-down reactor for reaction and mixing. The mixing time 2H, mixing speed 600r / min; then put mica powder, talc powder, diatomaceous earth, titanium dioxide into the paint let-down reactor and stir and mix, stirring time 3H, stirring speed 900r / min, the finished product is obtained after stirring evenly.

[0082] The composition includes in parts by weigh...

Embodiment 3

[0095] Compared with Embodiment 1, the differences of this embodiment are:

[0096] A kind of preparation method of normal temperature self-drying type one-component waterborne acrylic acid anticorrosion finish paint, it is characterized in that, preparation steps are as follows:

[0097] (1) To prepare a toughening agent, put polyamide and polyurethane into a mixing device in a weight ratio of 3:2 and mix them, and mix them uniformly to obtain a toughening agent;

[0098] (2) Put water-based acrylic resin, dispersant, defoamer, polyethylene glycol dioleate, toughener, lauryl alcohol ester, and deionized water into the paint let-down reactor for reaction and mixing. The mixing time 1.5H, mixing speed 580r / min; then put mica powder, talc powder, diatomaceous earth, titanium dioxide into the paint let-down reaction kettle and stir and mix, stirring time 2H, stirring speed 800r / min, the finished product is obtained after stirring evenly.

[0099] The composition includes in part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com