Preparation method of nano-porous palladium-based amorphous alloy

An amorphous alloy and nanoporous technology, which is applied in the field of preparation of amorphous/crystalline composite nanoporous materials, can solve the problems such as the inability to maintain the essential characteristics of amorphous, and achieve the effect of simple operation and reliable results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

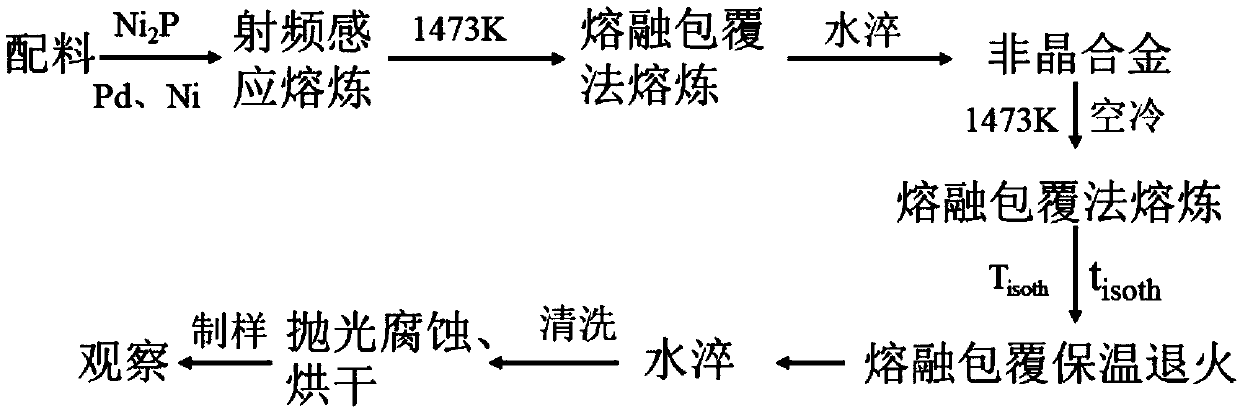

[0031] The schematic diagram of the preparation process of the present invention is as figure 1 shown.

[0032] 1) Select x=2.5 to prepare Pd 41.25 Ni 41.25 P 17.5 . Weigh 0.26253g of P and 0.99502g of Ni, both of which are sintered to form Ni 2 P ingot.

[0033] 2) Subsequent addition of 2.12627g of Pd and 0.17728g of Ni to Ni 2 In the P ingot, under the radio frequency induction heating, the elements are uniformly mixed to obtain Pd 41.25 Ni 41.25 P 17.5 alloy ingot.

[0034] 3) Take an appropriate amount of B 2 o 3 Put it into a cleaned quartz glass tube and dehydrate it at 923K for two hours.

[0035] 4) In a low vacuum environment at 1473K (10 -2 Torr) were treated by melt coating method, and the time was maintained at 90min.

[0036] 5) Take out the Pd 41.25 Ni 41.25 P 17.5 The quartz tube of the alloy sample is cooled in the air for 120s, placed in a 623K gold heating furnace, and kept at this temperature for 75min. After heat preservation, take out th...

Embodiment 2

[0043] 1) Choose x=3, prepare Pd 41.5 Ni 41.5 P 17 . Weigh 0.26253g of P and 0.99502g of Ni, both of which are sintered to form Ni 2 P ingot.

[0044] 2) Then add 2.19970g of Pd and 0.21850g of Ni to Ni 2 In the P ingot, under the radio frequency induction heating, the elements are uniformly mixed to obtain Pd 41.5 Ni 41.5 P 17 alloy ingot.

[0045] Same as 3) and 4) of the implementation example.

[0046] 5) Take out the Pd 41.5 Ni 41.5 P 17 The quartz tube of the alloy sample is cooled in the air for 120s, placed in a 613K gold heating furnace, and kept at this temperature for 60min. After heat preservation, take out the quartz tube containing the sample, put it in water and quench it to room temperature, take out the sample for cleaning, and slice it for later use.

[0047] The following steps are the same as step 6) to step 10) in implementation example 1.

Embodiment 3

[0049] 1) Select x=3.5 to prepare Pd 41.75 Ni 41.75 P 16.5 . Weigh 0.26253g of P and 0.99502g of Ni, both of which are sintered to form Ni 2 P ingot.

[0050] 2) Subsequent addition of 2.28058g of Pd and 0.26280g of Ni to Ni 2 In the P ingot, under the radio frequency induction heating, the elements are uniformly mixed to obtain Pd 41.75 Ni 41.75 P 16.5 alloy ingot.

[0051] The steps are the same as 3) and 4) in the implementation example 1.

[0052] 5) Take out the Pd 41.75 Ni 41.75 P 16.5 The quartz tube of the alloy sample is cooled in the air for 150s, placed in a 593K gold heating furnace, and kept at this temperature for 30min.

[0053] The next steps are the same as step 6) to step 10) in implementation example 1.

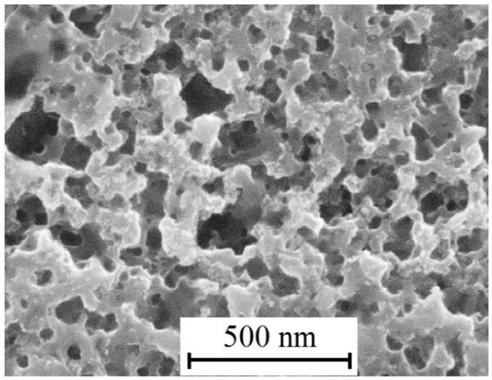

[0054] Microindentation tests showed that nanoporous Pd (40+x / 2) Ni (40+x / 2) P (20-x) It has the ability of local anti-injury. Scanning electron microscope image of indentation test Figure 5 shown. Figure 5 b and c represent the enlarge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com