Preparation method of cobalt-based bimetallic sulfide negative electrode material and application thereof

A negative electrode material and bimetal technology, which is applied to the preparation field of negative electrode material cobalt nickel sulfide, can solve the problems of low energy density of capacitors and the like, and achieve the effect of improving electrochemical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Put the cleaned nickel foam in the center of the high temperature diffusion furnace. Before heating, argon gas with a flow rate of 100 sccm was introduced for 30 minutes to remove the air, and then the temperature in the furnace was rapidly increased to 1000 °C at a rate of 10 °C / min. At this time, hydrogen gas was introduced with a flow rate of 50 sccm to maintain After 30 minutes, methane is introduced, the flow rate of methane is 5 sccm, the time of methane is 4 minutes, methane and hydrogen are turned off at the same time after 4 minutes, and the temperature in the furnace is lowered to room temperature under an argon atmosphere, and graphene on the surface can be obtained. layer of nickel foam.

[0034] Step 2: Weigh 1mmol of ferric nitrate and 1mol of nickel nitrate and dissolve in 35mL of deionized water, stir for 10min to obtain a transparent solution, add 4mmol of hexamethylenetetramine and 2mmol of ammonium fluoride under magnetic stirring to dissolve ...

Embodiment 2

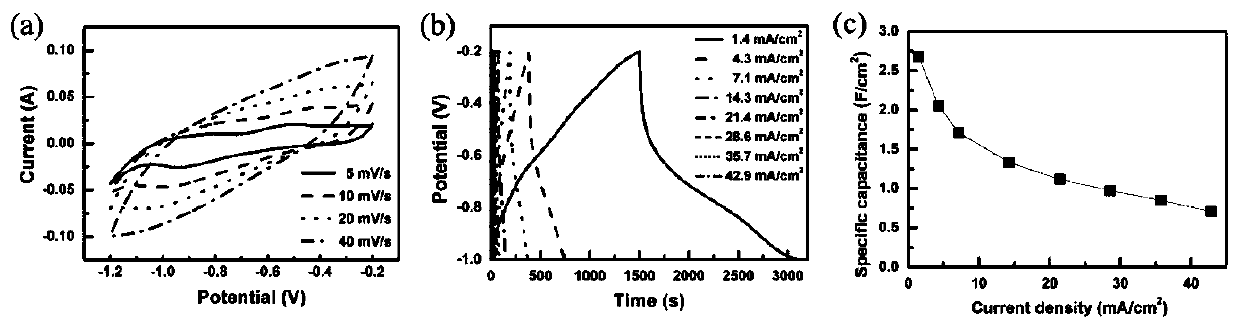

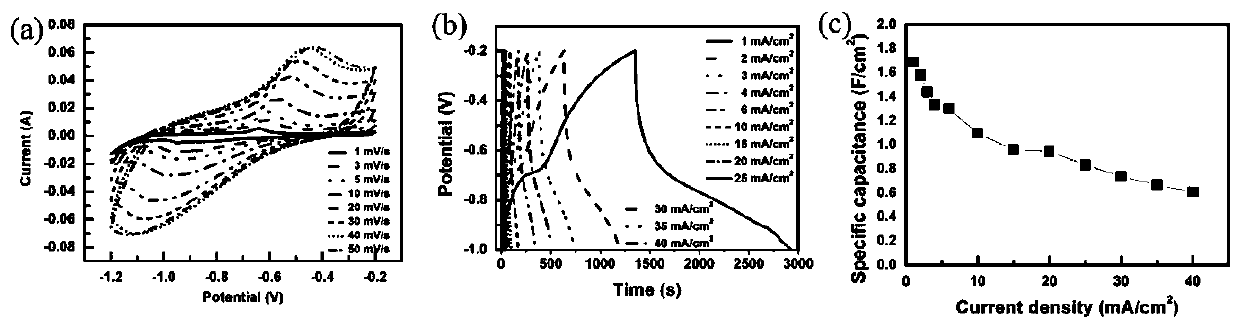

[0038] Compared with embodiment 1, embodiment 2 replaces nickel nitrate with ferric nitrate, and all the other are identical with embodiment 1, figure 2 The electrochemical performance of the sample obtained for Example 2.

Embodiment 3

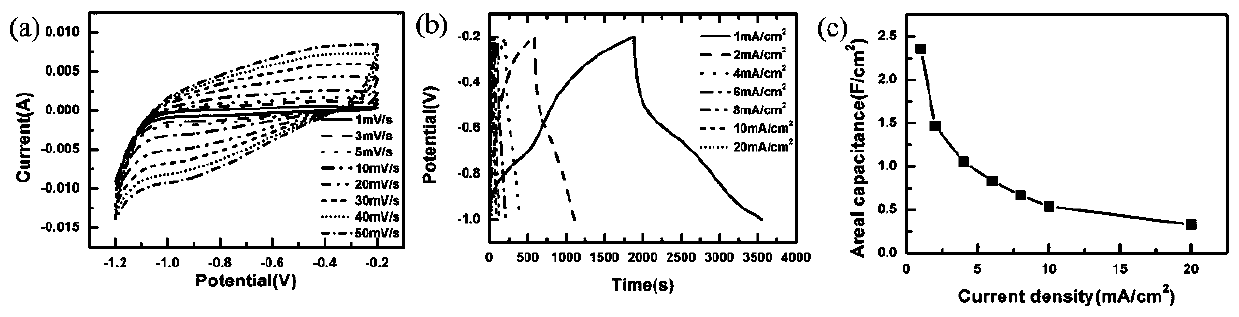

[0040] Compared with embodiment 1, embodiment 3 replaces nickel nitrate with ammonium molybdate, and all the other are identical with embodiment 1, image 3 The electrochemical performance of the sample obtained for Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com