Weeding master batch for biodegradable agricultural film, and preparation method thereof

A biodegradable and agricultural film technology is applied in the field of herbicidal biodegradable agricultural film masterbatch and its preparation, which can solve the problems of rarely being effectively utilized, and achieve high light resistance, lower production costs, and low light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

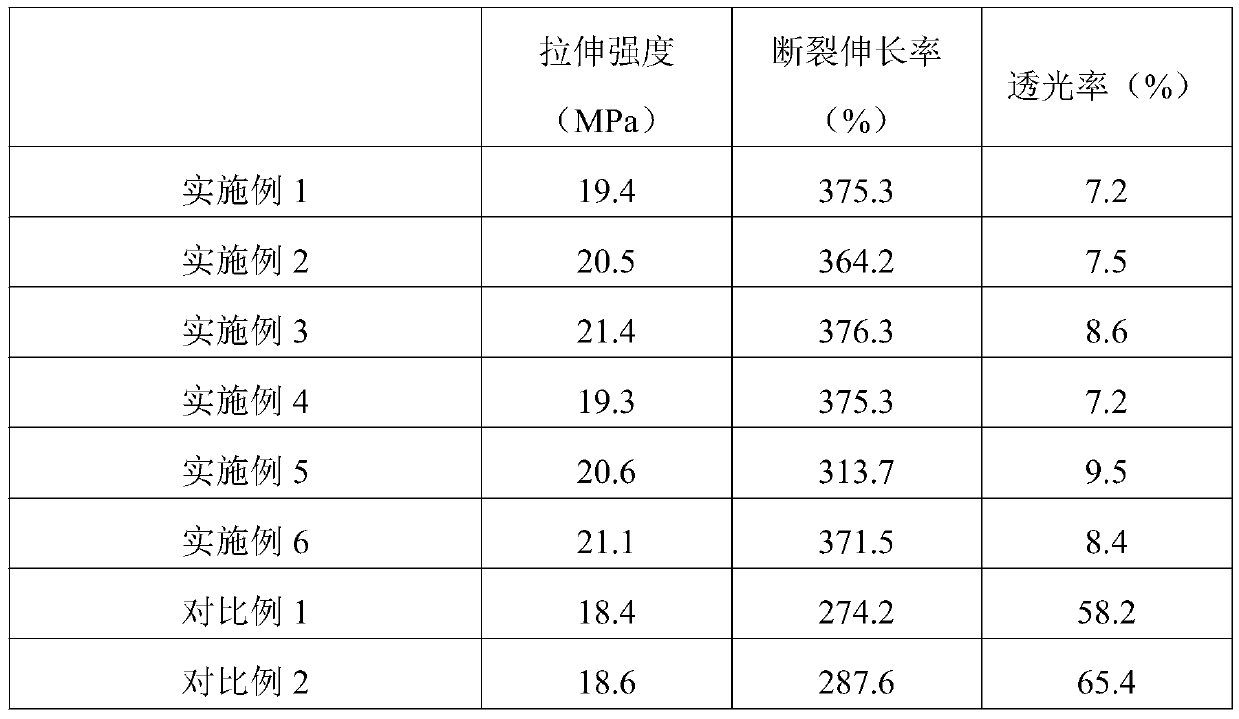

Examples

Embodiment 1

[0075] A kind of masterbatch for herbicide biodegradable agricultural film of the present embodiment is made up of the raw material of following parts by weight:

[0076] 60 parts of poly(butyleneadipate-co-terephthalate), PBAT, 10 parts of corn starch, 20 parts of pulping waste liquid extract, 10 parts of calcium carbonate, 2 citrates 1 part, 1 part of o-hydroxybenzophenone, 1 part of zinc stearate, 2 parts of phosphite.

[0077] The preparation method of the weeding biodegradable agricultural film masterbatch of the present embodiment is as follows:

[0078] Step 1, drying, pulverizing and sieving the pulping waste liquid extract to obtain the pulping waste liquid extract of 4500-5000 mesh;

[0079] 60 parts of PBAT, 10 parts of corn starch, 20 parts of pulping waste extract, 10 parts of calcium carbonate, 2 parts of citrate, 1 part of o-hydroxybenzophenone, 1 part of zinc stearate and 2 parts of phosphorous acid The ester is added into the high-speed blender in proportion...

Embodiment 2

[0082] A kind of masterbatch for herbicide biodegradable agricultural film of the present embodiment is made up of the raw material of following parts by weight:

[0083] 60 parts of polybutylene adipate / terephthalate (PBAT), 10 parts of tapioca starch, 20 parts of pulp residue, 10 parts of kaolin, 2 parts of citrate, 1 part of o-hydroxybenzophenone, stearic acid 1 part of zinc, 2 parts of phosphite.

[0084] The preparation method of the weeding biodegradable agricultural film masterbatch of the present embodiment is as follows:

[0085] Step 1, drying, pulverizing and sieving pulp residue to obtain pulp residue of 50-100 mesh;

[0086] Add 60 parts of PBAT, 10 parts of tapioca starch, 20 parts of pulp residue, 10 parts of kaolin, 2 parts of citrate, 1 part of o-hydroxybenzophenone, 1 part of zinc stearate and 2 parts of phosphite into the high-speed In a blender, mix for 10 minutes at a temperature of 10°C and a rotation speed of 10 rpm to obtain an initial mixture;

[00...

Embodiment 3

[0089] A kind of masterbatch for herbicide biodegradable agricultural film of the present embodiment is made up of the raw material of following parts by weight: polyadipate / butylene terephthalate (PBAT) 50 parts, polylactic acid (polylactic acid, PLA ) 10 parts, tapioca starch 10 parts, pulping waste liquid extract 20 parts, kaolin 10 parts, citrate 2 parts, o-hydroxybenzophenone 1 part, zinc stearate 1 part, phosphite 2 parts.

[0090] The preparation method of the weeding biodegradable agricultural film masterbatch of the present embodiment is as follows:

[0091] Step 1, drying, pulverizing, and sieving the pulping waste liquid extract to obtain a pulping waste liquid extract of 400 to 500 mesh;

[0092] 50 parts of PBAT, 10 parts of PLA, 10 parts of tapioca starch, 20 parts of pulping waste extract, 10 parts of kaolin, 2 parts of citrate, 1 part of o-hydroxybenzophenone, 1 part of zinc stearate and 2 Parts of phosphite were added in proportion to the high-speed blender, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com