In-vitro fine granule fat preparation integrated machine

An all-in-one, fine-particle technology, applied in medical science, surgery, etc., can solve problems such as fat cell necrosis, ensure cell activity, solve low ADSCs content, and improve clinical liposuction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

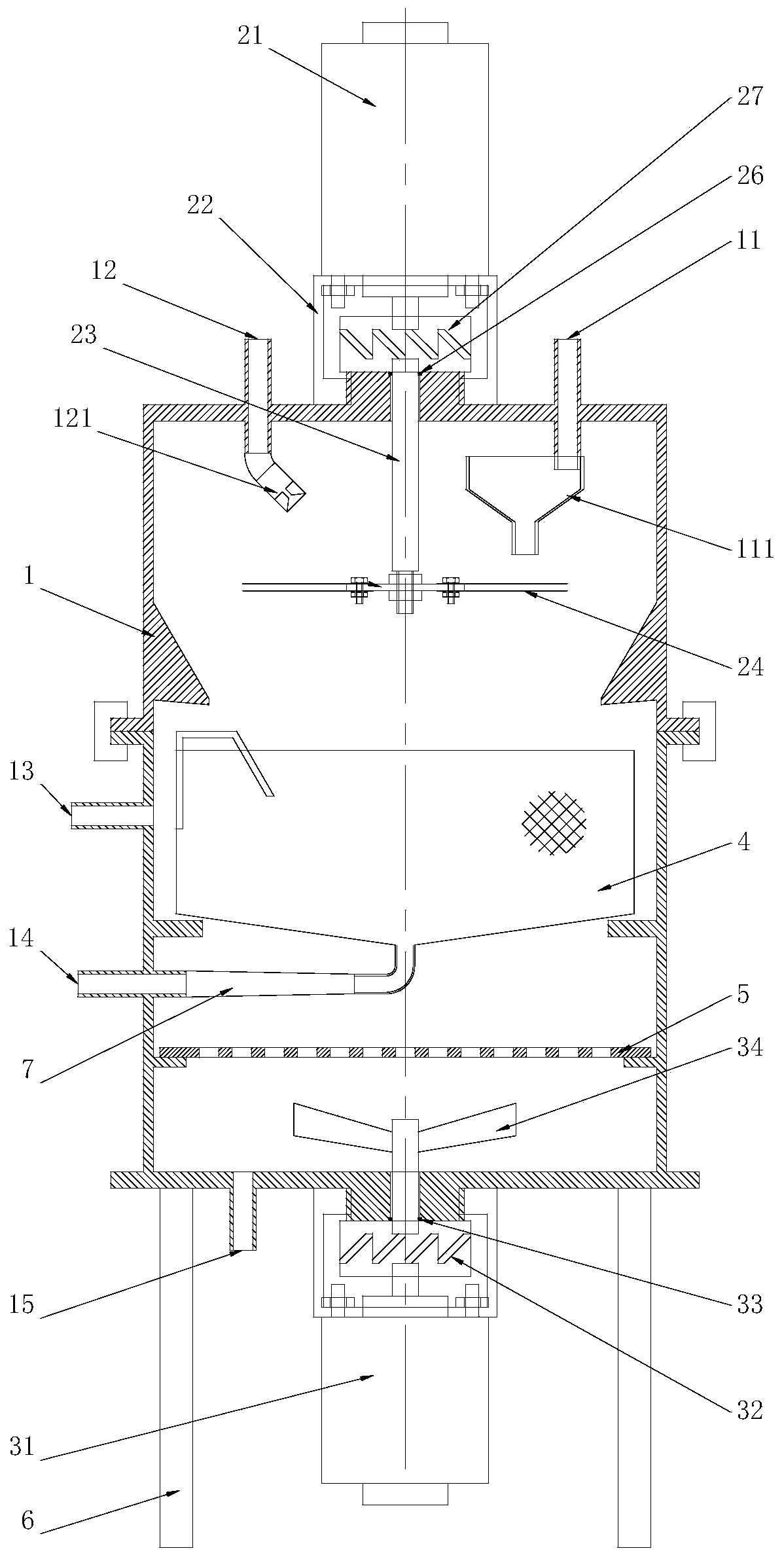

[0031] Such as figure 1 As shown, this embodiment, as the core of the device, includes a cylinder 1, the cylinder 1 is supported on the ground by the feet 6, a cavity is formed in the middle of the cylinder 1, and a liposuction port is provided on the cylinder 1 11. Water inlet 12, negative pressure drainage port 13, fat discharge collection port 14 and sewage outlet 15, the inlet of the liposuction port 11 is connected with a large-diameter liposuction tube (φ of the large-diameter liposuction tube ≥ 4mm, side hole Caliber area S≥10mm 2 ), the negative pressure outlet 13 is connected with a high negative pressure suction pipe (the high negative pressure here is a negative pressure value of 0.02~0.07Mpa), and a fat particle cutting device is arranged in the cylinder body 1.

[0032] The fat particle cutting device includes a blade set arranged directly below the liposuction port 11 in the cylinder body 1 and a first motor 21 that drives the blade set to rotate, and the first ...

Embodiment 2

[0040] This embodiment is further improved on the basis of Embodiment 1. The cylinder body 1 is provided with a nozzle on the water inlet, and the nozzle faces the blade group. The four sides and the bottom surface of the disc 4 are filter screens and upper openings. The filter screen aperture of the collecting disc 4 is smaller than the fat particles after cutting. The bottom of the collecting disc 4 is provided with a valve through the hose line 7 and the fat discharge collection port. In communication, the negative pressure drain port 13 of the cylinder body 1 is arranged on the outer side of the collecting pan 4, not higher than the upper opening of the collecting pan 4. With this embodiment, fat particles can be cleaned while cutting large fat particles. After cleaning, blood water is drawn out from the outlet of the cavity through negative pressure, while small fat particles remain in the collection tray due to the filtering effect of the filter. Inside, the syringe can ...

Embodiment 3

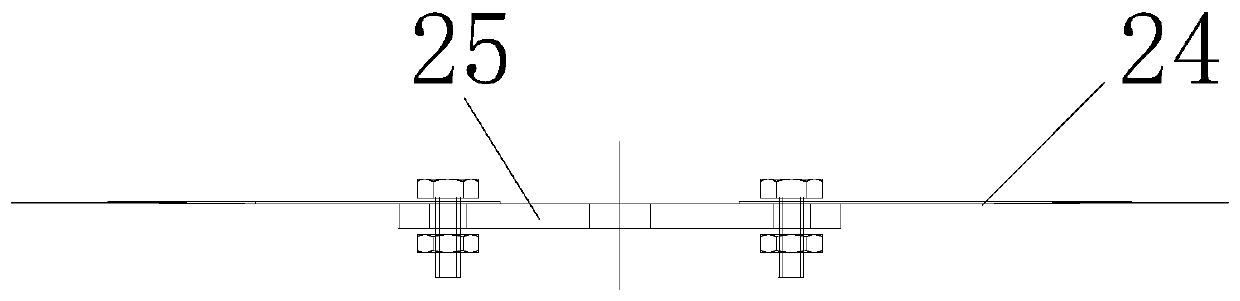

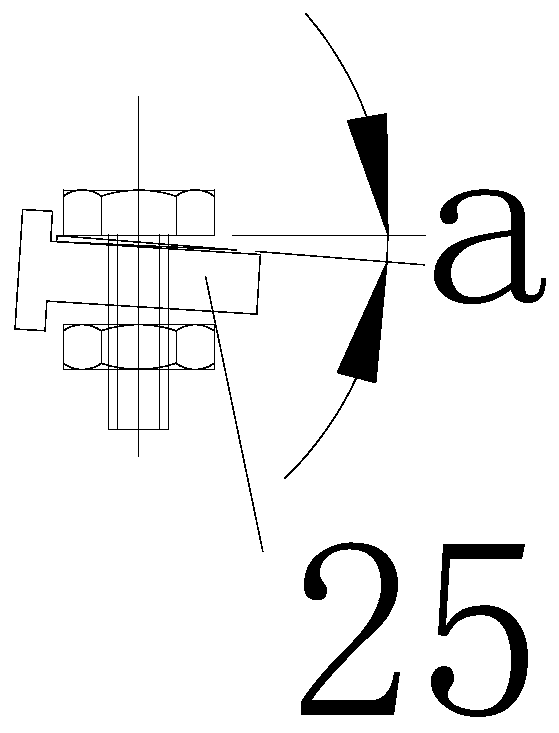

[0043] This embodiment is further improved on the basis of Embodiment 2. A stirring device is provided below the collecting pan 4 in the cylinder body 1. The collecting pan 4 and the stirring device are separated by a protective net 5. The stirring device includes a The stirring blade 34 and the second motor 31 that drives the stirring blade to rotate, the second motor 31 is connected with the second rotating shaft through the second transmission device 32, the stirring blade 34 is installed on the second rotating shaft, and the first The two rotating shafts are sealed and connected with the cylinder body 1 through the second sealing member 33, and the cavity includes a cutting area, a collecting area and a stirring area sequentially from top to bottom, the fat particle cutting device is arranged in the cutting area, and the collecting plate Set in the collection area, the stirring device is set in the stirring area, so that the stirring device will stir the cut and broken fat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com