Regeneration method of hydrogenation catalyst used for preparing aromatic amine antioxidant

A technology of hydrogenation catalyst and antioxidant, which is applied in the direction of catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of catalyst activity degradation, loss of active components, harsh reaction conditions, etc. Achieve the effects of reducing consumption costs, increasing application times, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

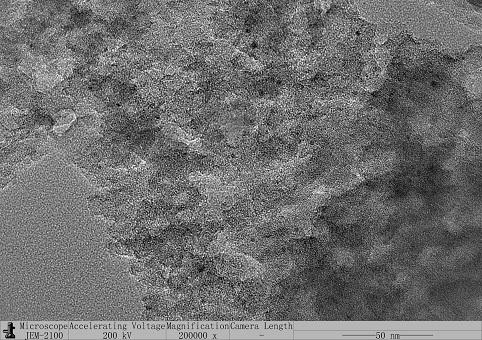

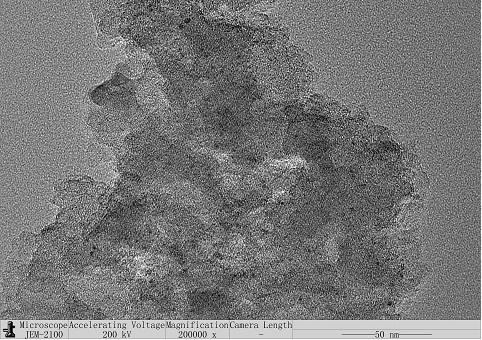

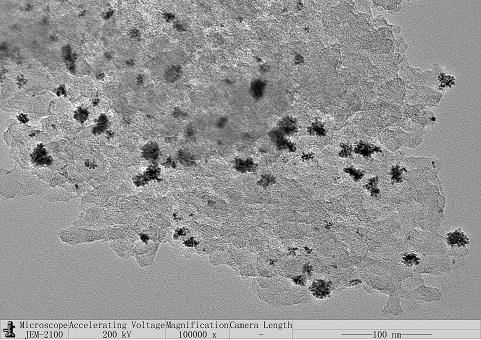

Image

Examples

Embodiment 1

[0026] Embodiment 1: the Pt / C catalyst regeneration of antioxidant IPPD preparation comprises the following steps:

[0027] (1) Disperse 1kg of the catalyst to be treated (denoted as Pt / C-1U, with an isoelectric point of 7.2) into 50kg of N-methylpyrrolidone to form a suspension, and transport it into the 2 In the replaced 100L regeneration kettle 1, heat up to 120°C for stirring and washing; after washing, the mixed material liquid is sent to a precision filter for filtration, and then 50kg of methanol is used to backflush the catalyst into the regeneration kettle 1, and the temperature is raised to 60°C for stirring again Wash and filter.

[0028] (2) Use 50kg of deionized water to recoil the catalyst to pre-use N 2 In the replaced 100L high-pressure regeneration kettle 2, the temperature was raised to 230°C for hydrothermal treatment; after the hydrothermal treatment, the mixed material liquid was sent to a precision filter for filtration to obtain the regenerated catalyst...

Embodiment 2

[0032] Embodiment 2: comparative experiment of regeneration method

[0033]Only the method of step (1) in Example 1 was used to wash and regenerate Pt / C-1U, and the treated catalyst was recorded as Pt / C-2R, and its isoelectric point was determined to be 7.

[0034] Perform performance evaluation on the regenerated Pt / C-2R: the evaluation experiment and analysis method are the same as in Example 1. The result is as follows.

[0035]

[0036] As can be seen from the experimental results in the table above, using the treated Pt / C-2R, after 6.2 hours of reaction, about 10% of 4-aminodiphenylamine was not converted, and the purity of the product by IPPD chromatographic analysis was only 88.7%. There is a slight improvement before, but the catalyst activity recovery effect is not obvious. It shows that the ideal regeneration effect cannot be achieved only by simple washing treatment.

Embodiment 3

[0038] The Pt / C-1U and Pt / C-1R before and after regeneration in Example 1 were respectively used as ketone-amine condensation reaction catalysts to evaluate the acid-catalyzed Schiff base formation performance: the molar ratio of acetone to 4-aminodiphenylamine was 5:1 , the mass ratio of catalyst dosage on dry basis to 4-aminodiphenylamine is 1:100, the reaction temperature is 90°C, and the kettle is replaced with nitrogen.

[0039] Samples were taken from the sampling port every 30 minutes, and the amount of Schiff base generated in the reaction solution was analyzed by gas chromatography. The specific analysis conditions were as follows: vaporization temperature 300°C, FID detector temperature 300°C, initial column temperature 80°C, initial column temperature The maintenance time is 2min, the heating rate is 15°C / min, the final column temperature is 300°C, the final column temperature is maintained for 5min, and the capillary column type is HP-5 (30m×0.32mm×0.25μm). Pt / C-1U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com