A kind of low-density colored silica particles with porous structure and its preparation

A silicon dioxide, porous structure technology, applied in inorganic chemistry, silicon compounds, chemical instruments and methods, etc., can solve the problems of lack of friction performance, high production energy consumption, difficult stirring, etc., and achieve bright color and low production cost. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

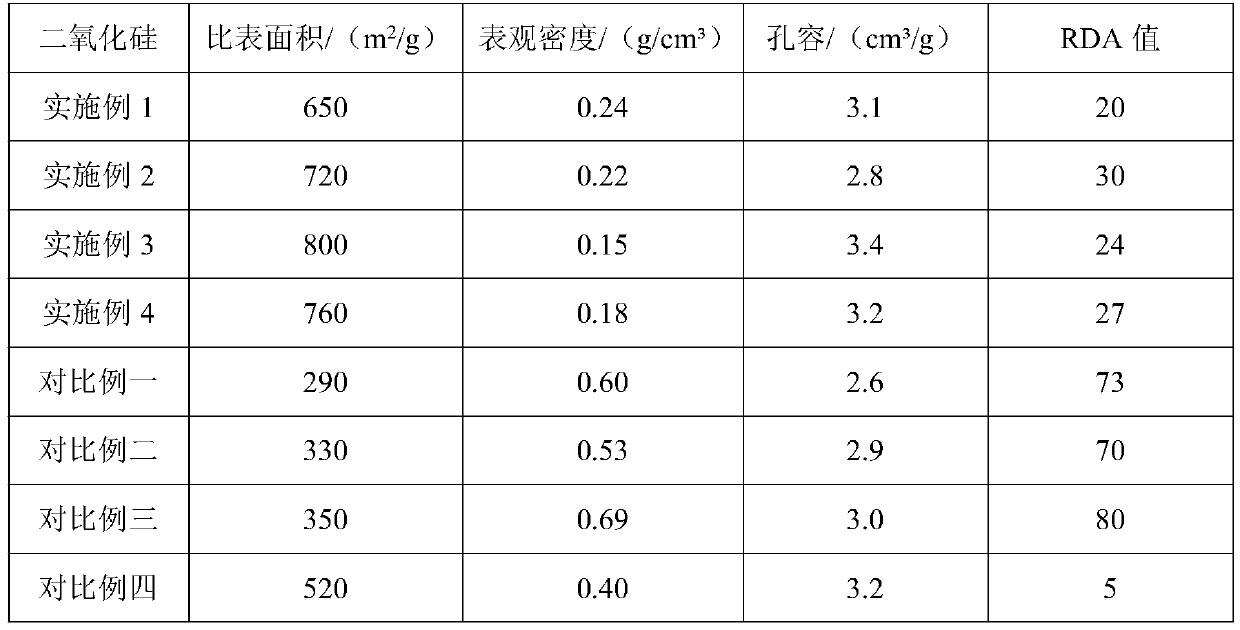

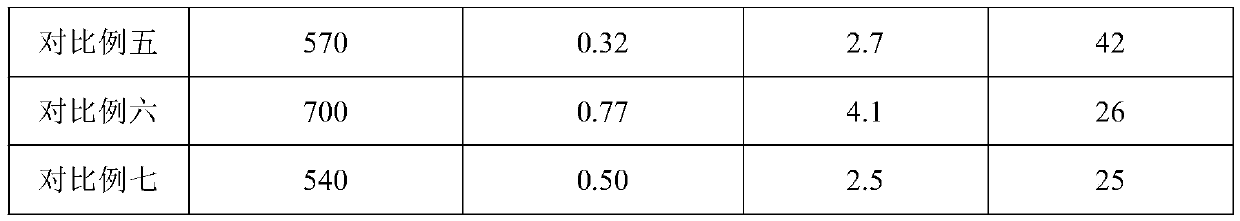

Examples

Embodiment 1

[0026] Embodiment 1, the present invention has the low-density green silica particle of porous structure and its preparation

[0027] S1. Inject 0.5m of sulfuric acid solution with a concentration of 0.5mol / L into the preparation tank 3 , then dropwise add a water glass solution with a concentration of 0.5mol / L and a modulus of 1.0 to a pH value of 1.5, and stir for 0.5h to prepare an acidic silica sol solution for subsequent use;

[0028] S2, inject concentration into reaction tank and be the sulfuric acid solution 3m of 0.8mol / L 3 , then add 1 kg of hydroxyethyl cellulose, stir for 20 min, then add dropwise the acidic silica sol solution and the water glass solution with a concentration of 0.8mol / L and a modulus of 3.3 at the same time, after the acidic silica sol solution has been added dropwise , continue to drop the water glass solution until the pH value is 3, then add 2 kg of edible green No. 3 solution with a mass percentage concentration of 10%, continue to drop the ...

Embodiment 2

[0031] Example 2. Low-density red silica particles with porous structure of the present invention and its preparation

[0032] S1. Inject 0.9m of sulfuric acid solution with a concentration of 0.8mol / L into the preparation tank 3 , then dropwise add a water glass solution with a concentration of 0.8mol / L and a modulus of 1.5 until the pH value is 2.5, and stir for 1 hour to obtain an acidic silica sol solution for subsequent use;

[0033] S2, inject concentration into reaction tank and be the sulfuric acid solution 4m of 1.2mol / L 3, then add 3 kg of hydroxyethyl cellulose, stir for 30 min, then add dropwise the acidic silica sol solution and the water glass solution with a concentration of 1.2mol / L and a modulus of 3.5 at the same time, after the acidic silica sol solution has been added dropwise , continue to drop the water glass solution until the pH value is 4, then add 3 kg of edible red No. 3 solution with a mass percentage concentration of 10%, continue to drop the wate...

Embodiment 3

[0036] Embodiment 3, the low-density blue silica particle with porous structure of the present invention and its preparation

[0037] S1. Inject 0.7m of sulfuric acid solution with a concentration of 0.6mol / L into the preparation tank 3 , then dropwise add a water glass solution with a concentration of 0.6mol / L and a modulus of 1.0 until the pH value is 2.0, and stir for 0.5h to prepare an acidic silica sol solution for subsequent use;

[0038] S2. Inject 3.5m of sulfuric acid solution with a concentration of 1.0mol / L into the reaction tank 3 , then add 2 kg of hydroxyethyl cellulose, stir for 25 min, then add dropwise the acidic silica sol solution and the water glass solution with a concentration of 1.0mol / L and a modulus of 3.4 at the same time, after the acidic silica sol solution has been added dropwise , continue to drop the water glass solution until the pH value is 3, then add 2 kg of edible blue No. 1 solution with a mass percentage concentration of 10%, continue to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com