Fluidized bed filler with reinforced denitrification function and preparation method thereof

A fluidized bed and functional technology, applied in the direction of chemical instruments and methods, sustainable biological treatment, water pollutants, etc., can solve the problems of inability to enhance the removal efficiency of total nitrogen in a targeted manner, and achieve enhanced removal efficiency of total nitrogen and enhanced contact and high mass transfer efficiency, total nitrogen removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

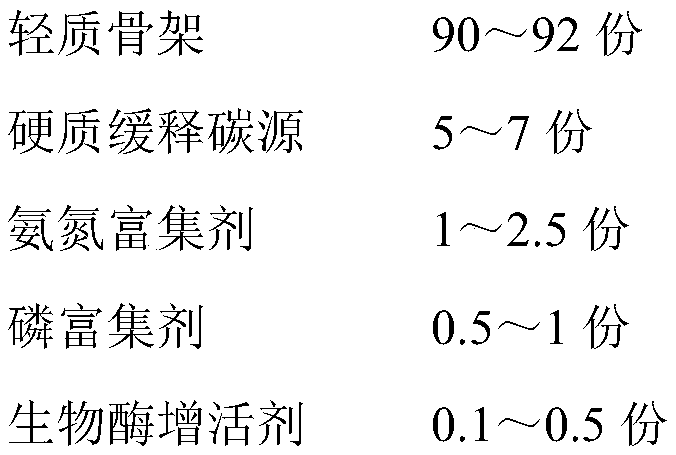

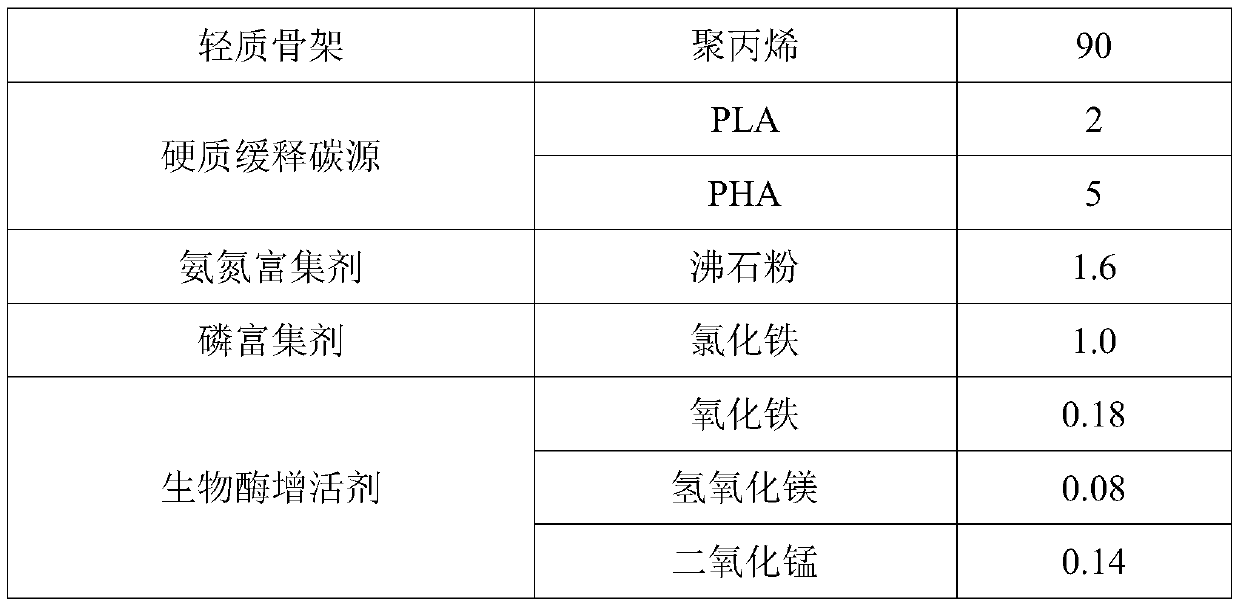

[0048] A fluidized bed filler with enhanced denitrification function, the components are as shown in Table 1, all in parts by weight:

[0049] Table 1

[0050]

[0051] The preparation method of the above-mentioned fluidized bed packing with enhanced denitrification function comprises the following steps:

[0052] (1) Place the above-mentioned raw materials in a mixer and fully mix them to obtain mixed raw materials;

[0053] (2) Put the mixed raw material prepared in step (1) into a 75-type single-screw extruder, heat it to 180-190° C., and extrude it through an extrusion die to obtain a cylindrical filler rod with a diameter of 25 mm;

[0054] (3) Cut the cylindrical filler rod prepared in step (2) into filler particles with a length of 8 mm.

Embodiment 2

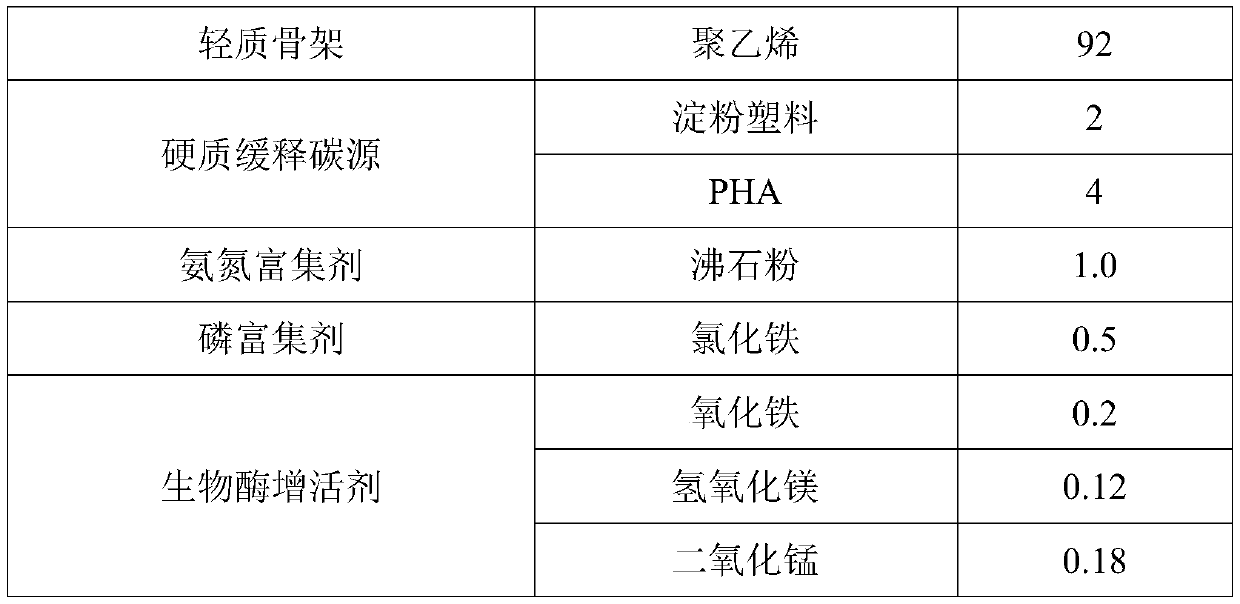

[0056] The fluidized bed filler with enhanced denitrification function as described in Example 1, the difference is that the components are as shown in Table 2, all in parts by weight:

[0057] Table 2

[0058]

Embodiment 3

[0060] The fluidized bed filler with enhanced denitrification function as described in Example 1, the difference is that the components are as shown in Table 3, all in parts by weight:

[0061] table 3

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com