Preparation method of nano-yttrium-stabilized zirconia-alumina composite powder

A technology of zirconia powder and composite powder, applied in the field of powder material preparation, can solve the problems of narrow particle size distribution, difficult to synthesize high-performance composite powder, small particle size, etc., and achieve the effect of simple operation and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

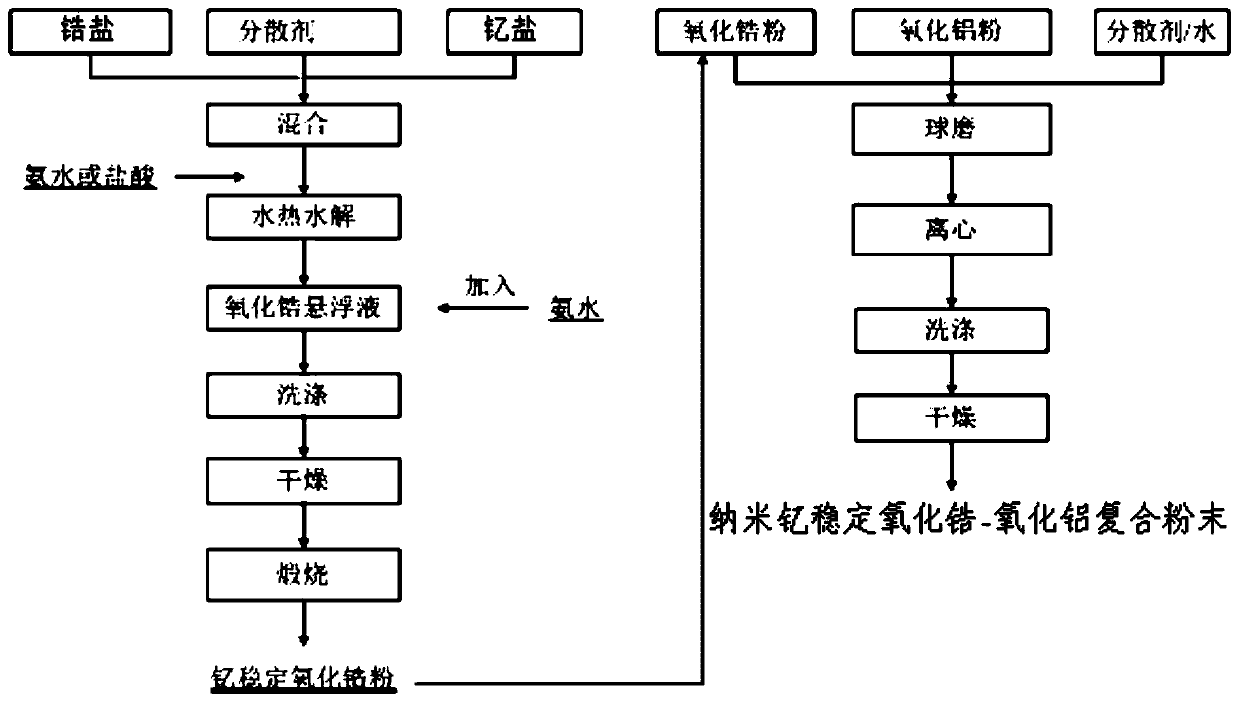

[0032] A method for preparing nano-yttrium stabilized zirconia-alumina powder by hydrothermal hydrolysis-ball milling mixing mode, the preparation method comprising the following steps:

[0033] 1) Reaction solution preparation method: prepare zirconium oxychloride, yttrium chloride, dispersant raw material solution, its Zr 4+Concentration 0.1~2.5mol / L, Zr 4+ with Y 3+ The molar concentration ratio is 99:2~90:20, the concentration of dispersant is 0.5~5g / L, the raw material solution is placed in the reaction kettle, under the condition of temperature 25~90℃, high speed stirring 300~10000r / min, through the mist Add the concentration of 0.5-6mol / L ammonia solution or 0.1-3mol / L hydrochloric acid solution at 1-10000mL / min to adjust the raw material solution H + Concentration, so that Zr in the solution 4+ Partial hydrolysis to generate crystal nuclei, adjust the solution H + The concentration is 0.1-5mol / L to control the amount of crystal nuclei generated by hydrolysis, that ...

Embodiment 1

[0040] (1) Preparation of ZrOCl 2 , YCl 3 , hydroxypropyl cellulose mixed solution, solution C Zr 4+ =0.6mol / L, C Y 3+ =0.0245mol / L (the molar ratio is Zr 4+ :Y 3+ =98:4), the final H + The concentration is 1.2mol / L, and the concentration of hydroxypropyl cellulose is 0.5g / L to obtain the hydrothermal reaction solution;

[0041] (2) Transfer the obtained solution to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, raise the temperature to 180° C. for 12 hours of hydrothermal reaction, and cool after the hydrothermal reaction is completed to obtain a hydrated zirconia suspension;

[0042] (3) Add 10% dilute ammonia solution dropwise at 10 mL / min to Y 3+ Uniformly precipitate on the surface of hydrated zirconia in the form of yttrium hydroxide until the pH of the hydrated zirconia suspension is greater than 9. After the yttrium sinking reaction is completed, statically age for 24 hours and centrifuge to obtain the hydrated zirconia precipitat...

Embodiment 2

[0046] (1) Preparation of ZrOCl 2 , YCl 3 , hydroxypropyl cellulose mixed solution, the raw material solution is placed in the reaction kettle, under 60 ℃ water bath, 500r / min stirring, by adding 2.8mol / L ammonia solution to adjust the final reaction solution H + concentration, so that the solution final C H + =1.2mol / L, C Zr 4+ =1.0mol / L, C Y 3+ =0.0408mol / L (molar ratio Zr 4+ :Y 3+ =98:4), the hydroxypropyl cellulose concentration is 0.5g / L, obtains hydrothermal reaction solution;

[0047] (2) Transfer the solution obtained in (1) to a polytetrafluoroethylene-lined stainless steel hydrothermal reaction kettle, raise the temperature to 180 ° C for 12 hours of hydrothermal reaction, after the hydrothermal reaction is completed, take out the hydrothermal reaction kettle to cool, and obtain hydration oxidation zirconium suspension;

[0048] (3) Add 10% dilute ammonia solution dropwise at 10 mL / min to Y 3+ Uniformly precipitate on the surface of hydrated zirconia in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com