Electronically conductive metal organic frame film and preparation method and application thereof

A metal-organic framework, electronic conduction technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problem of inability to obtain thickness and quality EC-MOFs nanoporous thin film, and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First the glass substrate is cleaned. That is, the glass substrate was ultrasonically washed for half an hour in a mixed solution of acetone, isopropanol and water with a volume ratio of 1:1:1, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Put it in the prepared piranha solution (volume ratio of sulfuric acid:hydrogen peroxide is 7:3), heat to 100°C, cook for about half an hour, cool down, then pour out the piranha solution, (Note: Piranha The solution is very corrosive, and corresponding protection measures must be taken), ultrasonically washed twice with deionized water, and stored in deionized water.

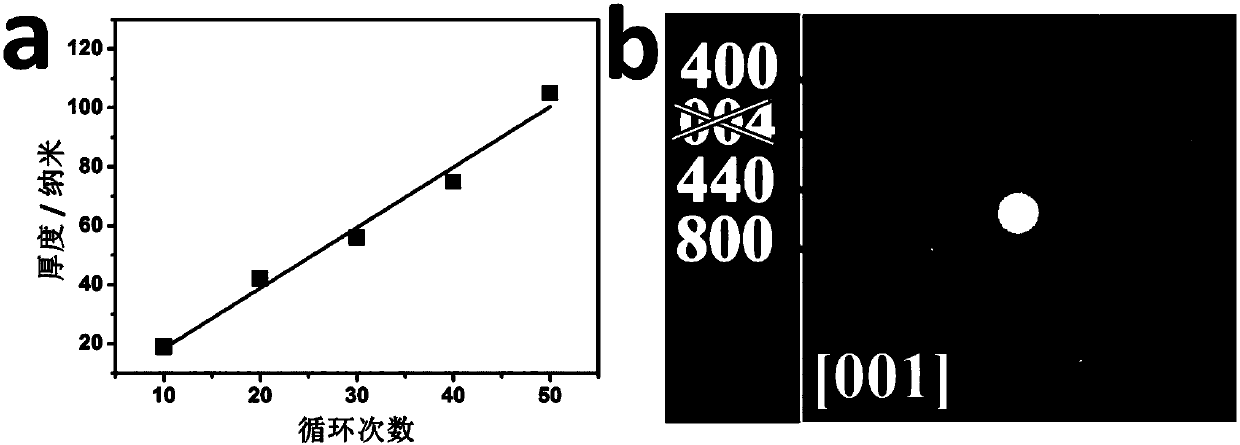

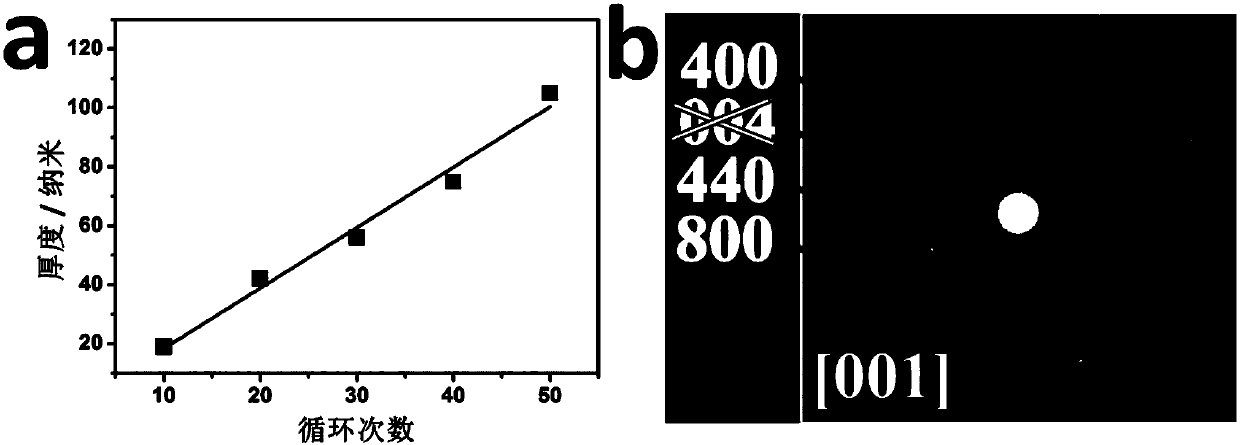

[0043] Prepare 0.01-1mol / L copper acetate solution and 0.01-1mol / L methanol solution of HHTP organic ligand, fix the above glass substrate on a substrate, first take 3mL copper acetate solution, spray for about 20 seconds, then Spray with 4 mL of ethanol and dry with nitrogen. Then take 6 mL o...

Embodiment 2

[0047] First the sapphire substrate is cleaned. That is, the sapphire substrate was ultrasonically washed for half an hour in a mixed solution of acetone, isopropanol and water with a volume ratio of 1:1:1, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Configure 0.01mol / L ethanol solution of copper nitrate and 0.1mol / L ethanol solution of 2,3,6,7,10,11-hexaaminotriphenylene (HATP) organic ligand, and fix the above substrate on a substrate First, take 3mL of copper acetate ethanol solution, spray for about 20 seconds, then spray with 4mL of ethanol, and blow dry with nitrogen. Immediately after that, 6 mL of ethanol solution of BHT organic ligand was sprayed for about 40 seconds, followed by spray washing with 4 mL of ethanol, and blown dry with nitrogen. This is a cycle, the thickness of the grown film is one layer, and this step is repeated to grow a film with a specific thickness.

Embodiment 3

[0049] Firstly, the Si substrate is cleaned. That is, the substrate was ultrasonically washed for half an hour in a mixed solution of acetone, isopropanol and water with a volume ratio of 1:1:1, and then ultrasonically washed with deionized water for 10 minutes. Then rinse with ethanol and blow dry with nitrogen. Configure 0.01mol / L ethanol solution of nickel nitrate and 0.1mol / L ethanol solution of 2,3,6,7,10,11-hexaaminotriphenylene (HATP) organic ligand, and fix the above substrate on a substrate First, take 3mL of nickel nitrate ethanol solution, spray for about 20 seconds, then spray with 4mL of ethanol, and blow dry with nitrogen. Immediately after that, 6 mL of ethanol solution of BHT organic ligand was sprayed for about 40 seconds, followed by spray washing with 4 mL of ethanol, and blown dry with nitrogen. This is a cycle, the thickness of the grown film is one layer, and this step is repeated to grow a film with a specific thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com