Method for preparing single-photon light source and component

A single-photon light source and single-photon technology, applied in electrical components, semiconductor devices, nano optics, etc., can solve the problems of low-quality single-photon light source and poor light source spectrum type, and achieve good light source spectrum type and small half-height width , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

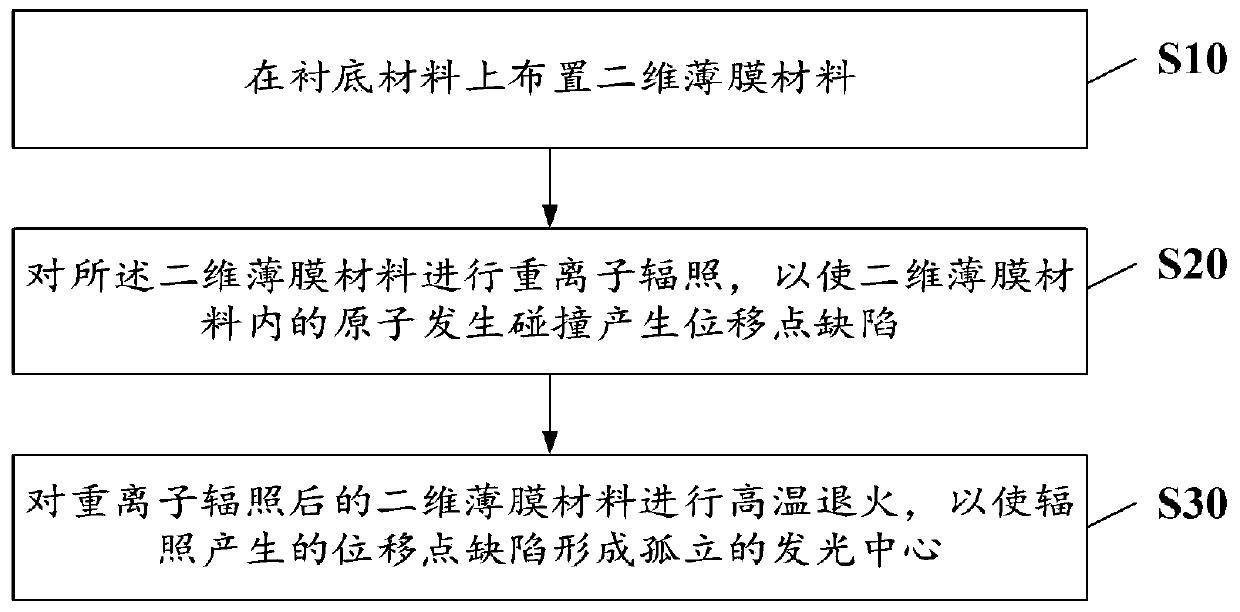

[0030] Please refer to figure 1 , figure 1 A flow chart of a method for preparing a single-photon light source provided in this embodiment is shown. The specific preparation method includes:

[0031] Step S10: Arranging a two-dimensional thin film material on the substrate material.

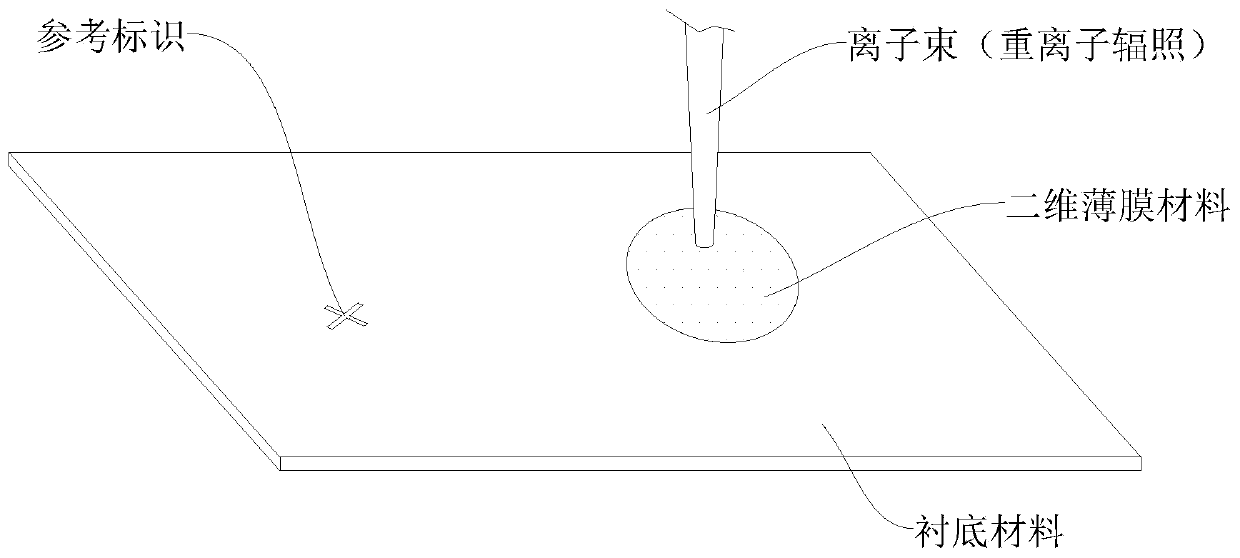

[0032] Step S20: performing heavy ion irradiation on the two-dimensional thin film material, so that atoms in the two-dimensional thin film material collide to generate displacement point defects.

[0033] Step S30: performing high-temperature annealing on the two-dimensional thin film material irradiated by heavy ions, so that the displaced point defects generated by the irradiation form isolated luminescent centers.

[0034] In step S10, the two-dimensional thin film material includes but not limited to semiconductor thin film materials such as boron nitride, gallium nitride, gallium arsenide, diamond and silicon carbide. In this embodiment, a more preferred material is a boron nitride two-...

no. 2 example

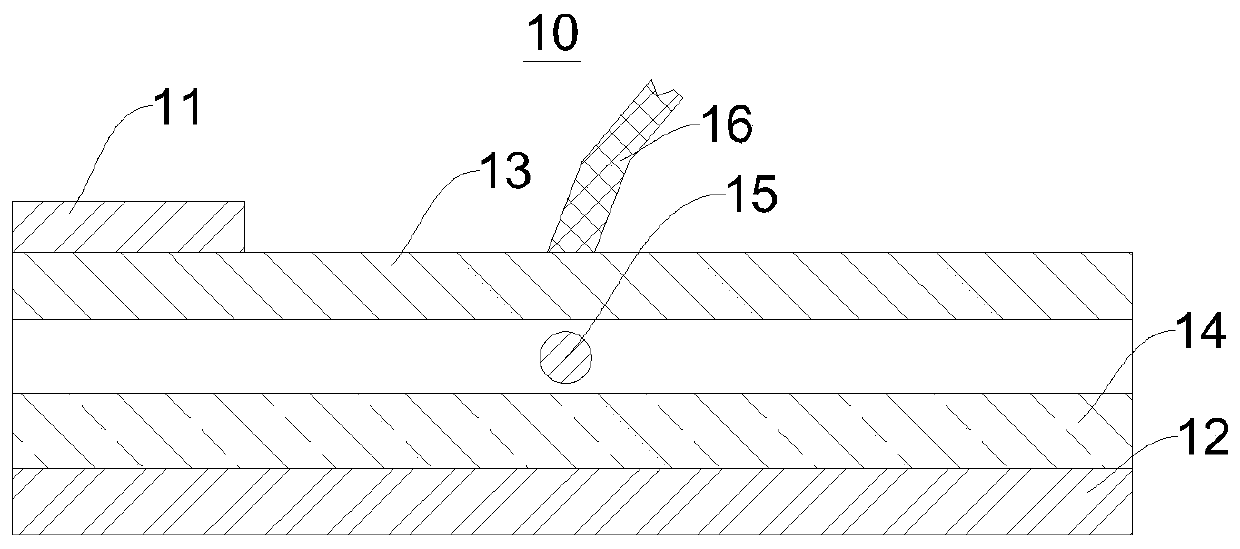

[0046] Based on the same inventive concept, the second embodiment of the present application provides a single-photon component 10 , and the single-photon light-emitting center in the single-photon component 10 can be manufactured by using the preparation method of the single-photon light source in the first embodiment. Please refer to image 3 Specifically, the single photon component 10 includes: a first electrode 11, a second electrode 12, a P-type material 13, an N-type material 14, a two-dimensional film material 15 with a single-photon emission center, and a Guided mode fiber 16 for the optical signal of the photon luminescence center; the P-type material 13 and the N-type material 14 are located on both sides of the two-dimensional thin film material 15, and the first electrode 11 is located on the P-type material 13 The side away from the two-dimensional thin film material 15, the second electrode 12 is located on the side of the N-type material 14 away from the two-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com