Preparation method and application of double-hetero-element-doped porous carbon nanorod negative electrode material

A technology of negative electrode materials and heteroelements is applied in the field of negative electrode materials for lithium/sodium ion batteries, and achieves the effects of good large-scale application potential, simple operation process, and cheap preparation of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

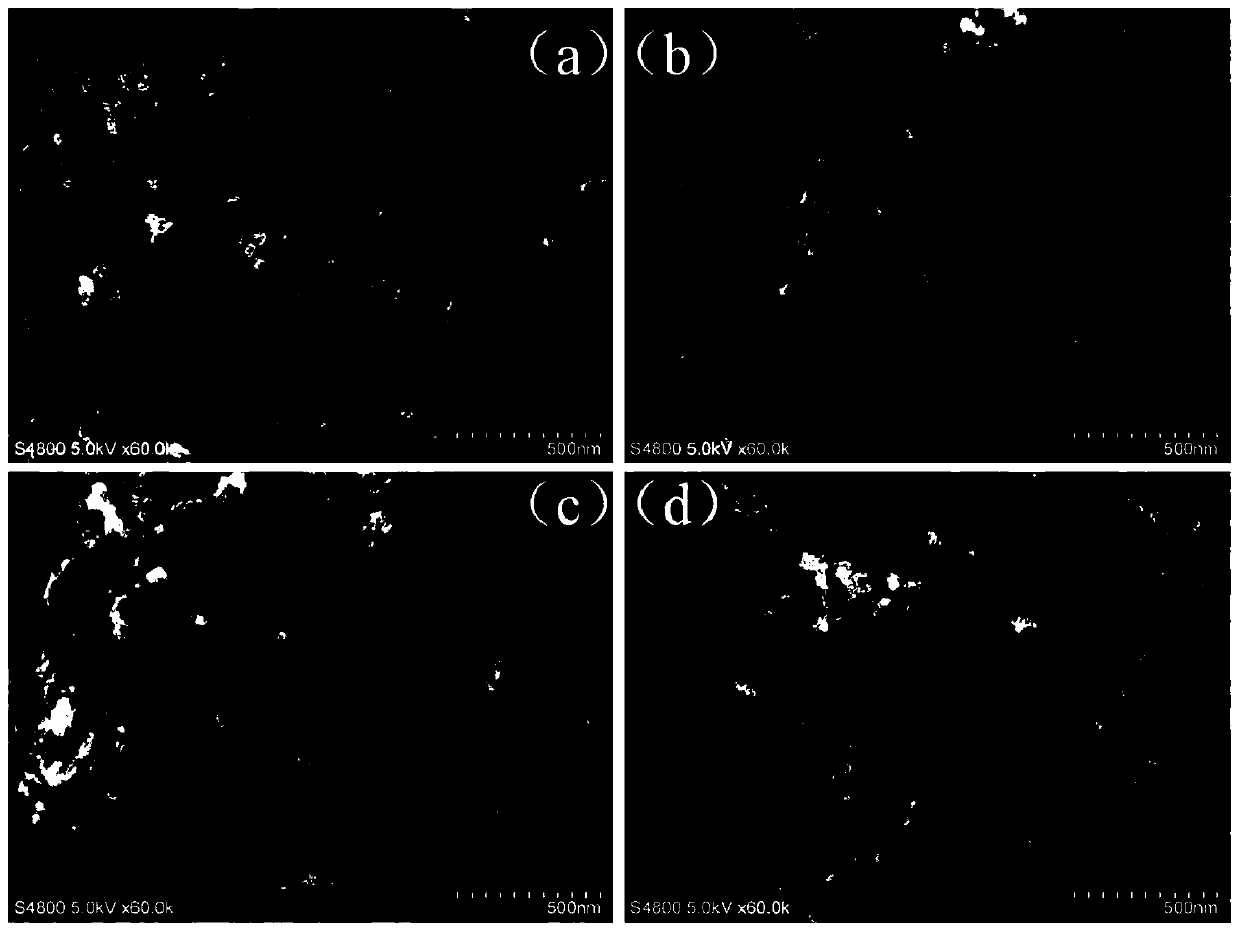

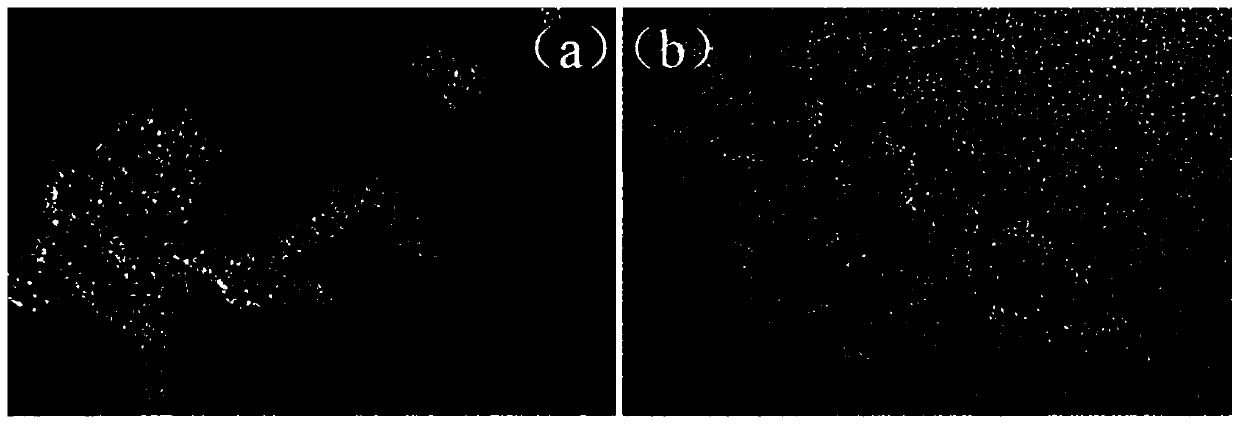

[0026] Disperse 1.71 g of ammonium persulfate in 60 mL of deionized water, add 1 g of LuDOX-40 SiO 2 (40nm) gel and 1g of phytic acid aqueous solution, fully ultrasonically stirred under ice bath conditions until uniform dispersion; another 0.55mL aniline was dispersed in 60mL deionized water, fully ultrasonically stirred under ice bath conditions until uniformly dissolved, then stirred at high speed In the case of , quickly pour the prepared solution into the solution in the previous step, let it sit for 24 hours, then filter it with suction, wash it with deionized water for 3 to 5 times, and dry it in vacuum at 70°C for 3 to 5 hours to prepare a blue-black precipitate; The precipitate was treated at 600 °C for 12 h under Ar protection gas, treated with 10% dilute HF acid solution for 12 h, washed with deionized water for 3 to 5 times, and vacuum-dried at 70 °C for 3 h to prepare heteroelement-doped porous carbon nanorod material.

[0027] After the sintered material was ful...

Embodiment 2

[0029] Disperse 0.8 g of ammonium persulfate in 60 mL of deionized water, add 1 g of JK-5-25 SiO 2 (5nm) gel and 1g of phytic acid aqueous solution, fully ultrasonically stirred under ice bath conditions until uniformly dispersed; another 0.275 mL of aniline was dispersed in 60mL deionized water, fully ultrasonically stirred under ice bath conditions until uniformly dissolved, and stirred at high speed In the case of , quickly pour the prepared solution into the solution in the previous step, let it sit for 24 hours, then filter it with suction, wash it with deionized water for 3 to 5 times, and dry it in vacuum at 70°C for 3 to 5 hours to prepare a blue-black precipitate; The precipitate was treated at 700 °C for 12 h under Ar protection gas, treated with 15% dilute HF acid solution for 8 h, washed with deionized water for 3 to 5 times, and vacuum-dried at 70 °C for 3 h to prepare heteroelement-doped porous carbon nanorod material.

[0030] After the sintered material was fu...

Embodiment 3

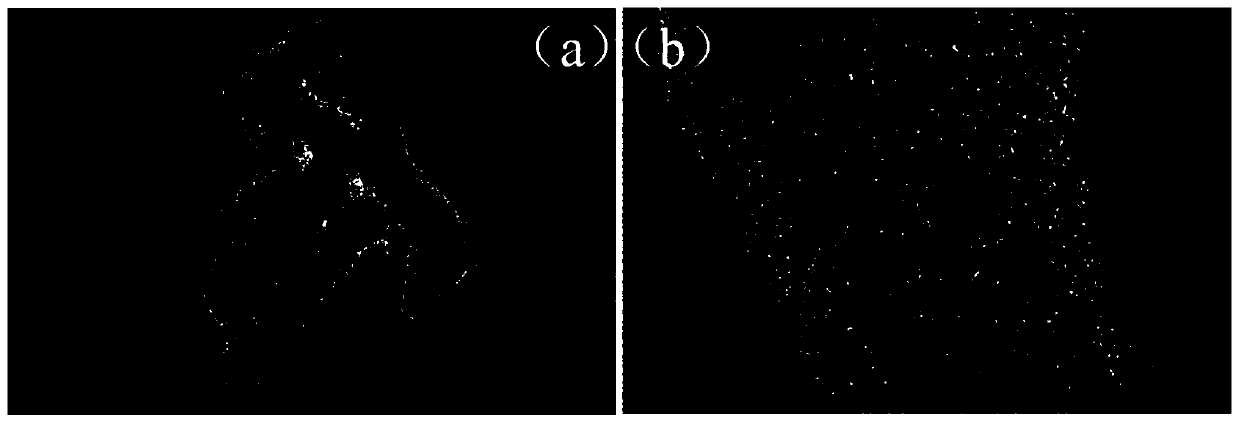

[0032] Disperse 2.4 g of ammonium persulfate in 60 mL of deionized water, add 5 g of JK-5-25 SiO 2(5nm) and 1.65 g of phytic acid aqueous solution, fully ultrasonically stirred under ice bath conditions until uniform dispersion; another 0.55 mL of aniline was dispersed in 60 mL of deionized water, fully ultrasonically stirred under ice bath conditions until uniformly dissolved, then stirred at high speed In the case of , quickly pour the prepared solution into the solution in the previous step, let it sit for 24 hours, then filter it with suction, wash it with deionized water for 3 to 5 times, and dry it in vacuum at 70°C for 3 to 5 hours to prepare a blue-black precipitate; The precipitate was treated at 1000 °C for 5 h under the protective gas of He gas, treated with 20% dilute HF acid solution for 5 h, washed with deionized water for 3 to 5 times, and dried in vacuum at 70 °C for 3 h to prepare heteroelement-doped porous carbon nanorod material.

[0033] After the sintered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com