Manufacturing method of hangover-eliminating enzyme powder and composition for relieving hangover comprising thereof

The technology of a hangover enzyme and composition is applied in the field of the preparation of a hangover-eliminating enzyme powder and a composition for eliminating hangover containing the component, which can solve the problems of insufficient effect, inability to eliminate hangover and detoxification, and little effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

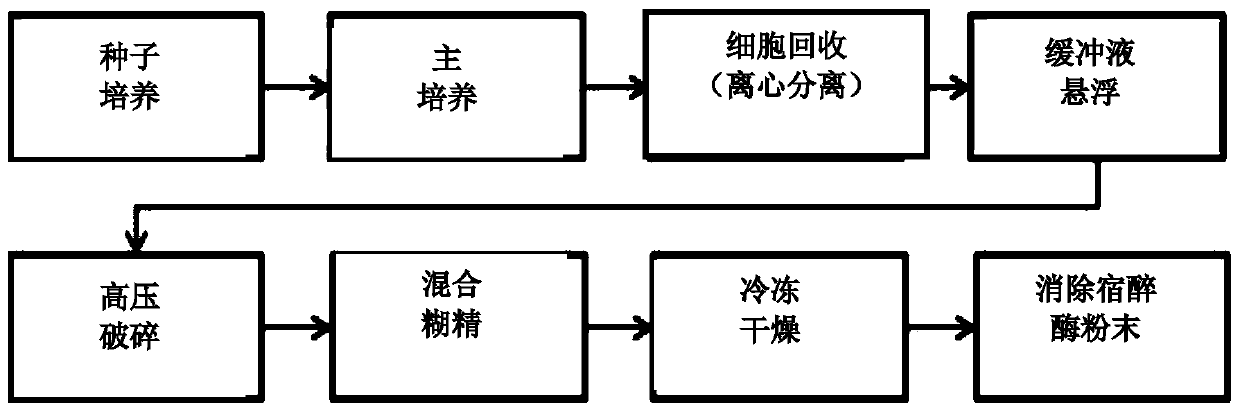

[0083] Hangover Elimination Enzyme Powder

[0084] An acetic acid strain (Acetobacter pasteurianus VA2, Acetobacter pasteurianus VA2) was subjected to acetic acid fermentation to express ADH and ALDH, and to prepare an enzyme complex comprising the ADH and ALDH. The specific method is as follows.

[0085] The acetic acid bacteria were cultured for 16 to 24 hours in a pre-medium of yeast extract powder 0.5%, D-mannitol 2.5% and peptone 0.3%. Mix yeast extract powder 0.5% to 1%, soytone 0.5% to 1.5%, hydrous crystalline glucose 2.5% to 7.5%, manganese sulfate 0.01% to 0.05%, and mix fermentation alcohol 1% to 5% in this medium , inoculate the pre-cultured strain, and cultivate it at 25 to 30° C. at 200 to 300 rpm for 24 to 36 hours. After cultivation, the pH is preferably 3.5 to 4.0, and the acetic acid concentration is preferably 2.0 to 4.0% by weight. Then the supernatant was removed by centrifugation (10,000×g, 20 minutes), and the precipitate was washed 2 to 3 times with...

preparation example 2

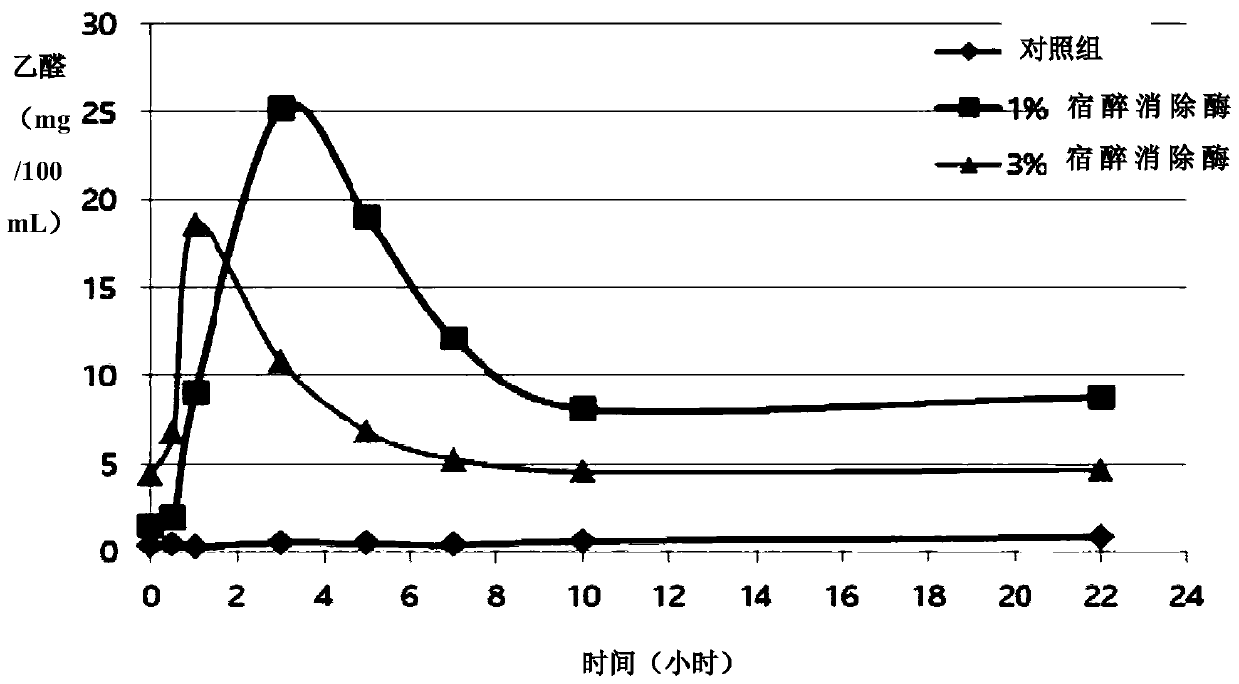

[0087] Hangover Elimination Enzyme Complex

[0088] A hangover-eliminating enzyme complex was prepared by adding grain fermented enzyme powder (Application No. 10-2017-0080405) to the hangover-eliminating enzyme powder obtained in . Then, 103 mg / kg of hangover-eliminating enzyme powder and 103 mg / kg of grain fermentation enzyme powder (1:1 weight ratio), hereinafter expressed as CA+FG, were administered to the animal model.

Embodiment 1

[0092] Determination of Enzyme Activity of Hangover Enzyme Powder

[0093] Activity Analysis Method of Alcohol Dehydrogenase

[0094] First, 200 μl of the above-prepared sample was placed in an E-tube, and the enzyme activity was removed by heating at 100° C. for 30 minutes or more. 1.3 mL of 50 mM sodium phosphate buffer (pH 8.8, sodium phosphate buffer) and 1.5 mL of 15 mM β-NAD solution were mixed with 0.1 mL of 95% (v / v) ethanol to prepare a substrate reaction solution so that the total solution was 2.9mL.

[0095] 6.67 μl of the sample and 193.3 μl of the prepared reaction solution were mixed and dispensed into a 96-well microplate (blank = enzyme solution heated at 100° C. for 30 minutes). After that, after measuring the absorbance at 340 nm and 25° C. for 0-10 minutes using a multiple reader (Multiple reader), the activity of alcohol dehydrogenase was analyzed using the following .

[0096] Activity analysis method of acetaldehyde dehydrogenase

[0097] First, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com