3D honeycomb-like foam carbon material, preparation method and applications thereof

A honeycomb and foam carbon technology, applied in the field of materials, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

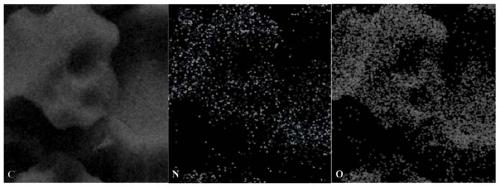

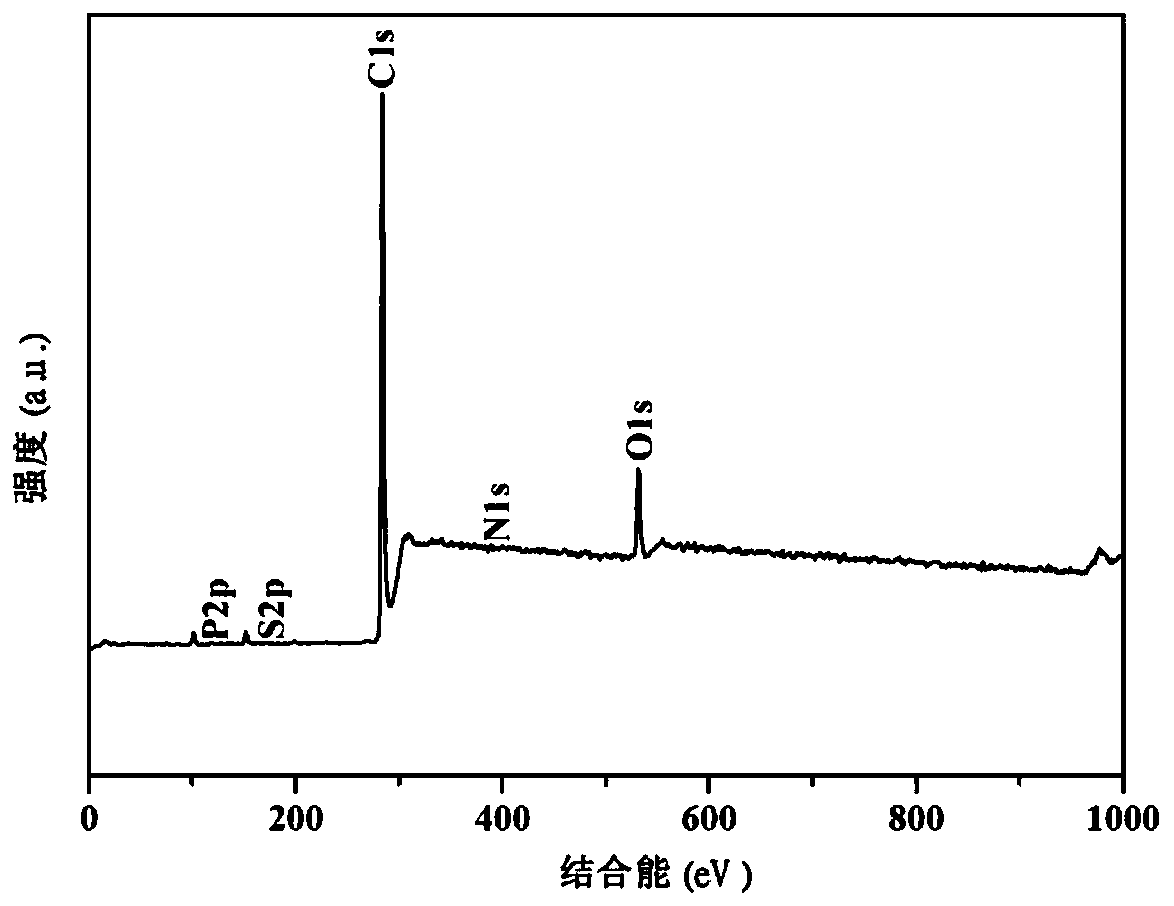

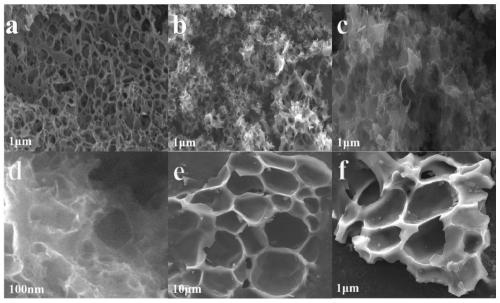

[0032] Preparation of 3D honeycomb foam carbon material

[0033] (1) Add tartary buckwheat flour with a particle size of 60 mesh in the KOH solution at a mass ratio of 2:1 to alkali, and stir at a speed of 40r / min for 1.5h to obtain a gel;

[0034] (2) Dry the gel prepared in step (1) at 80°C for 12h, then place it in a tube furnace, under the protection of argon, raise the temperature at a rate of 3°C / min to 200°C for 1h, and then continue Raise the temperature at a rate of 3°C / min to 400°C for 2 hours, then raise the temperature to 700°C at a rate of 3°C / min, then hold it for 2 hours, and finally cool to room temperature to prepare a 3D cellular foam carbon material precursor;

[0035] (3) The 3D honeycomb foam carbon material precursor prepared in step (2) was repeatedly suction-filtered and washed with 15% hydrochloric acid solution and deionized water, and then dried at 80°C for 12 hours to obtain a 3D honeycomb carbon foam material.

Embodiment 2

[0037] Preparation of 3D honeycomb foam carbon material

[0038] (1) Add tartary buckwheat powder with a particle size of 40 mesh in the NaOH solution at a mass ratio of 2:3 to the alkali, and stir for 2 hours at a speed of 30 r / min to obtain a gel;

[0039](2) Dry the gel prepared in step (1) at 70°C for 16h and place it in a tube furnace under the protection of helium, raise the temperature to 200°C at a rate of 5°C / min, keep it warm for 1h, and then continue Raise the temperature to 400°C at a rate of 5°C / min and then hold it for 2 hours, then raise the temperature to 700°C at a rate of 5°C / min, hold it for 2 hours, and finally cool it to room temperature to prepare a 3D cellular foam carbon material precursor;

[0040] (3) The 3D honeycomb foam carbon material precursor prepared in step (2) was repeatedly suction-filtered and washed with 15% hydrochloric acid solution and deionized water, and then dried at 70°C for 16 hours to obtain a 3D honeycomb carbon foam material. ...

Embodiment 3

[0042] Preparation of 3D honeycomb foam carbon material

[0043] (1) Add tartary buckwheat powder with a particle size of 80 mesh to the KOH solution at a mass ratio of 1:2 to the alkali, and stir for 2 hours at a speed of 20 r / min to obtain a gel;

[0044] (2) Dry the gel prepared in step (1) at 60°C for 20 hours, then place it in a tube furnace, under the protection of argon, heat it up to 100°C at a rate of 4°C / min, keep it warm for 2 hours, and then continue Raise the temperature to 300°C at a rate of 4°C / min and then hold it for 2 hours, then raise the temperature to 700°C at a rate of 4°C / min, hold it for 2 hours, and finally cool it to room temperature to prepare a 3D cellular foam carbon material precursor;

[0045] (3) The 3D honeycomb foam carbon material precursor prepared in step (2) was repeatedly suction-filtered and washed with 10% hydrochloric acid solution and deionized water, and then dried at 60°C for 20 hours to obtain a 3D honeycomb carbon foam material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com