High-performance molybdenum-based rare-earth ferrite magnetic core material

A ferrite core, high-performance technology, applied in the field of magnetic core material manufacturing, can solve the problems of cumbersome preparation process, high preparation cost, difficult operation, etc., and achieve the effects of simple process, improved mechanical strength, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

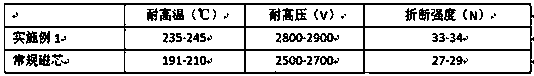

Examples

Embodiment 1

[0015] A high-performance molybdenum-based rare earth ferrite core material, including the following raw materials in weight fractions, 5 parts of iron sulfide, 11 parts of iron sulfate, 15 parts of potassium molybdate, 27 parts of ferric oxide, and ferric oxide 21 parts, 5 parts of lanthanum chloride, 9 parts of copper hydroxide, 2 parts of zinc carbonate, 7 parts of manganese dioxide, 2 parts of bentonite, 13 parts of zirconium dioxide, 11 parts of titanium tetrachloride, and 8 parts of molybdenum trioxide;

[0016] A method for preparing a high-performance molybdenum-based rare earth ferrite core material, the preparation steps are as follows: (1) ferric sulfide, ferric sulfate, potassium molybdate, ferric oxide, ferric oxide, lanthanum chloride, hydrogen Copper oxide, zinc carbonate and manganese dioxide are mixed evenly, then ground into powder in a nodular ink tank, and then dried at 75°C to obtain a mixed powder, and the mixed powder is calcined at 550°C for 3 hours; (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com