Uracil Schiff-base and preparation method and use thereof

A technology of uracil-Schiff base and semi-uracil, applied in the field of uracil-Schiff base and its preparation, can solve the problems of poor stabilization effect, opaque PVC products, poor PVC compatibility, etc., and achieves strong stability and high transparency , the effect of no three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

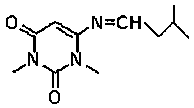

[0022] In a 1000 ml three-necked flask equipped with a stirring device, add 700 ml of water, add sulfuric acid to adjust pH: 3-4, add 5.60 g of 1,3-dimethyl-6-aminouracil, keep pH: 3-4 , until the uracil is completely dissolved, drop 3.11 g of isovaleraldehyde, a yellow precipitate is formed in the stirring reaction, filter, wash the filter cake three times, and dry to obtain the uracil Schiff base, whose structural formula is shown in formula (III). Yield: 95.1%, light yellow solid, melting range: 165-178℃, close to PVC melt flow temperature, purity: 95.5%, moisture: 3.5%, other impurities: ≤1.0%; 1H NMR (DMSO)δ : 0.83-0.88 (6H, 6Hz, 2CH3), 1.3 (1H, 1.3Hz, 1CH), 1.8-2.1 (2H, 1CH2,) 3.2 (6H, 1H, 2CH3), 4.2 (1H, 1.5 Hz, 1CH), ; IR(KBr): 3383, 3198, 2955, 1698, 1670, 1610 , 1496 , 1376 , 1050 , 788, 500 cm -1 .

[0023]

[0024] Formula (III).

Embodiment 2

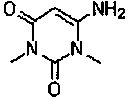

[0026] In a 1000 ml three-necked flask equipped with a stirring device, add 700 ml of water, add acetic acid to adjust pH: 3-4, add 5.60 g of 1,3-dimethyl-6-aminouracil, keep pH: 3-4 , until the uracil is completely dissolved, add 0.1g phase transfer catalyst, raise the temperature to 80°C, add 7.66g C14 aldehyde (myristal) dropwise, a yellow precipitate is formed in the stirring reaction, filter, wash the filter cake 3 times, and dry to obtain urea Pyrimidine Schiff base, whose structural formula is shown in formula (IV). Yield: 96.2%, light yellow solid, melting range: 141-156℃, good compatibility with PVC, purity: 94.8%, moisture: 3.7%, other impurities: ≤1.5%; 1H NMR (DMSO)δ: 0.83 -0.88 (6H, 6Hz, 2CH3), 1.3 (1H, 1.3 Hz, 1CH), 1.8-2.2 (24H, 12CH2), 3.2 (6H, 1H, 2CH3), 4.2 (1H, 1.5 Hz, 1CH), ; IR ( KBr): 3383, 3250, 3198, 2955, 1698, 1670, 1610 , 1496 , 1376 , 1050 , 788, 500 cm -1 . )

[0027]

[0028] Formula (IV)

Embodiment 3

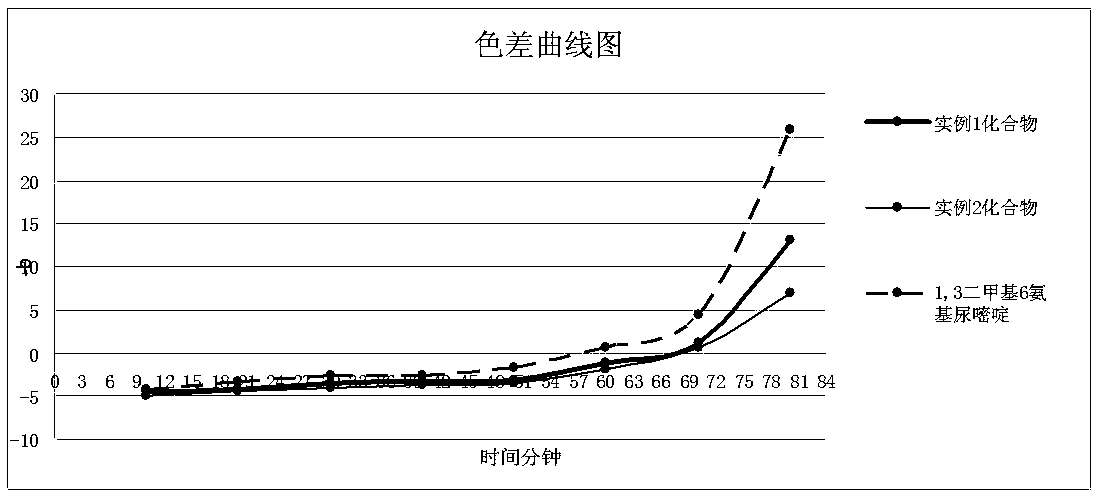

[0030] The compound of formula III in Example 1 and the compound of formula IV in Example 2, 1,3-dimethyl-6-semiuracil (DMAU), were respectively used as PVC heat stabilizers for double-roll test. The formula for the double-roll test is shown in Table 1:

[0031] Table 1: Uracil Schiff base PVC heat stabilizer double-roll test formula table

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com