A medium capable of promoting spore production of Bacillus subtilis and its application

A Bacillus subtilis culture medium technology, applied in the field of microbial engineering, can solve the problem of low number of spores produced by Bacillus subtilis, achieve the effects of reducing elimination rate, improving digestibility, and promoting spore production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The method for preparing animal feed (such as poultry feed, especially broiler feed) provided by the present invention includes liquid culture of Bacillus subtilis according to the above method, spray drying of the obtained culture solution, and mixing of the obtained dried product with basic nutrients .

[0023] According to the present invention, the spray drying is generally performed in a spray dryer. The inlet temperature of the spray dryer can be 150-200°C, and the outlet temperature can be 100-120°C. The duration of spray drying can be 10-60s. The carrier used in spray drying can be various commonly used carriers, generally those that do not affect the nutrition and taste of animal feed, preferably at least one of corn flour, corn husk, corn cob and water-soluble starch. The weight ratio of the carrier used in spray drying to the material to be dried (culture solution) is (0.5-1.5):1.

[0024] According to a preferred embodiment of the present invention, relative t...

Embodiment 1

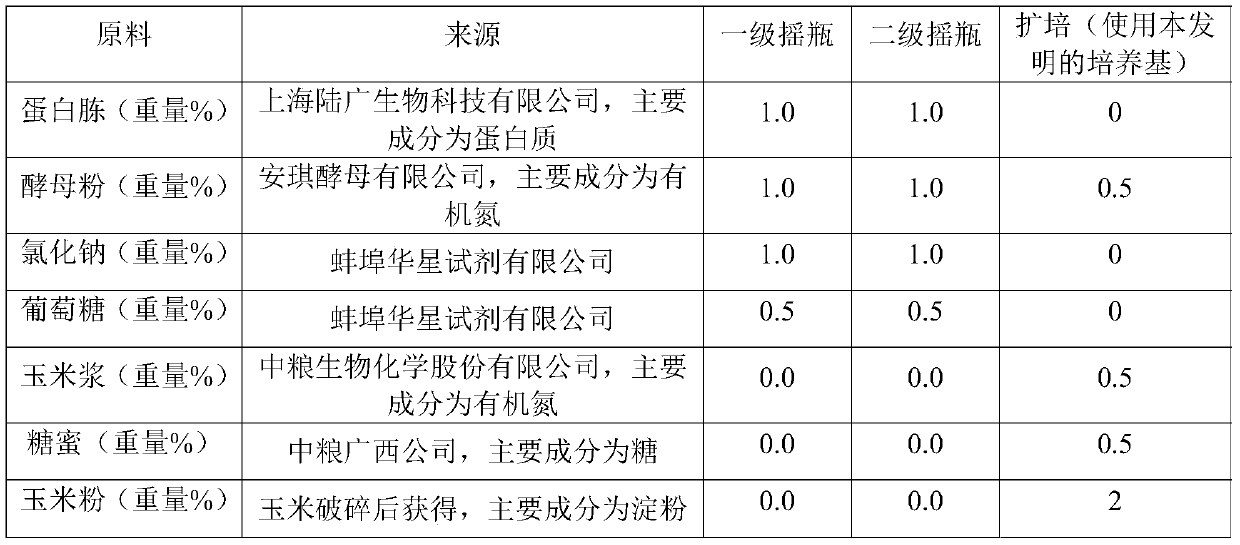

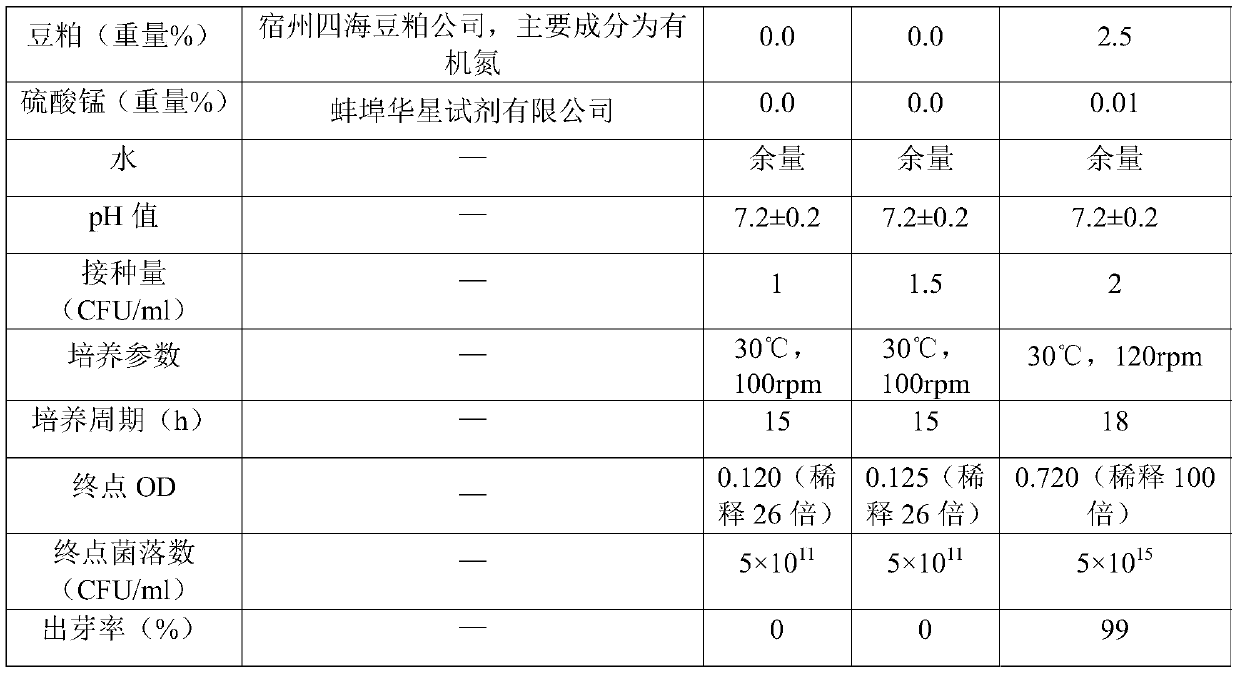

[0029] (1) According to the medium and conditions in Table 1, use a 250ml flask to perform primary shake flask and secondary shake flask (activation) on Bacillus subtilis, and then use an expansion tank with an effective volume of 400L to expand Bacillus subtilis Training.

[0030] Table 1

[0031]

[0032]

[0033] (2) Then spray-dry the culture solution in the expansion tank (see Table 1 for the characterization results such as germination rate) under the following conditions:

[0034] Spray carrier: corncob, the weight ratio of culture solution is 1:1

[0035] Inlet temperature: 150℃

[0036] Outlet temperature: 100℃

[0037] Duration: 10s

[0038] (3) Add the dried product obtained in step (2) to the diet of broilers, and add 5×10 per gram of diet. 14 The amount of CFU bacteria was added to obtain feed 1.

Embodiment 2

[0040] The feed was prepared according to the method of Example 1, except that 10 per gram of diet was added 14 The amount of CFU bacteria was added with the dried material to obtain feed 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com