Lubricating coating and preparation method thereof

A technology of lubricating coating and transition layer, applied in the field of lubricating coating and its preparation, can solve problems such as difficulty in obtaining service life and coating failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

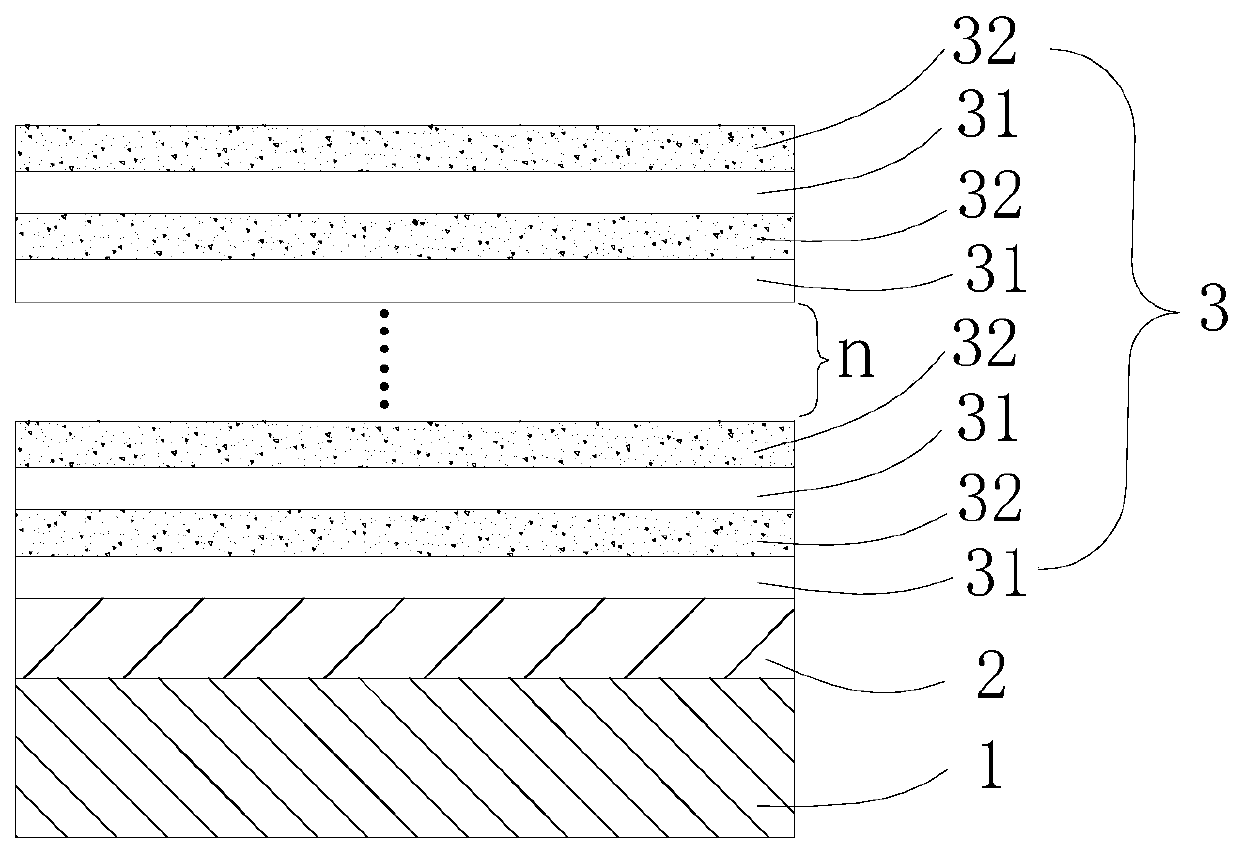

[0038] The present invention also provides a kind of preparation method of lubricating coating, comprises the following steps:

[0039] S1, providing the matrix;

[0040] S2, forming a transition layer on the surface of the substrate;

[0041] S3, using a V-Al alloy with a V content of 17at.% to 33at.% and an Al content of 67at.% to 83at.% as a target material, and depositing a functional layer on the surface of the transition layer by using a DC magnetron sputtering method, Wherein, the sputtering current of the target is 0.8A~1.2A, the bias voltage applied on the substrate is -50V~-200V, the amount of nitrogen gas is 35sccm~45sccm, and the amount of argon gas is 60sccm ~80sccm, after that, the hydrocarbon gas is introduced every 1 minute~10 minutes for 1 minute~10 minutes. VAlN layer and VAlCN layer.

[0042] In step S1, the substrate includes one of cemented carbide, titanium alloy, zirconium alloy and steel. And it is preferable to polish the surface of the substrate, ...

Embodiment 1

[0052] The cemented carbide substrate is surface polished, decontaminated by ultrasonic cleaning with acetone, dried and placed in the vacuum chamber of the vacuum coating equipment.

[0053] Pump down the vacuum chamber to below 3×10 -5 Torr, heated to 250°C, 40sccm argon gas was introduced into the vacuum chamber, the pressure was 2.3mTorr, the bias voltage applied to the substrate was -150V, and the substrate was etched for 20min with a linear ion source.

[0054] Tungsten is used as the target material, the sputtering current of the tungsten target is set to 3A, the flow rate of argon gas is 60 sccm, and the air pressure is 3.6 mTorr, and a tungsten transition layer of 300 nm is deposited by DC magnetron sputtering.

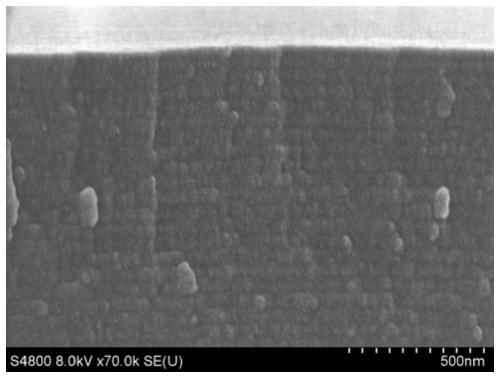

[0055] A V-Al alloy with a V content of 33 at.% and an Al content of 67 at.% was used as the target material, and 35 sccm of nitrogen gas and 70 sccm of argon gas were used, and methane gas was fed for 1 min every 2 min, and the flow rate of methane gas was 5...

Embodiment 2

[0060] The surface of the bearing steel substrate is polished, decontaminated by ultrasonic cleaning with acetone, dried and placed in the vacuum chamber of the vacuum coating equipment.

[0061] Pump down the vacuum chamber to below 3×10 -5 Torr, heated to 250°C, 40sccm argon gas was introduced into the vacuum chamber, the pressure was 2.3mTorr, the bias voltage applied to the substrate was -150V, and the substrate was etched for 20min with a linear ion source.

[0062] Chromium was used as the target material, the sputtering current of the chromium target was set to 3A, the argon gas flow rate was 60 sccm, and the air pressure was 3.6 mTorr, and a chromium transition layer of 200 nm was deposited by DC magnetron sputtering.

[0063] Adopt the V-Al alloy that V content is 33%, Al content is 67at.% as target material, pass into nitrogen 40sccm, argon 70sccm, pass into acetylene gas 1min every 5min, the flow rate of passing into acetylene gas is 5sccm, control The gas pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com