Alkaline silane rare-earth-doped treating agent for metal surface treatment and preparation method and application thereof

A technology of metal surface treatment and rare earth doping, applied in the direction of metal material coating process, etc., to achieve the effect of inhibiting corrosion reaction, good effect, simple and novel method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

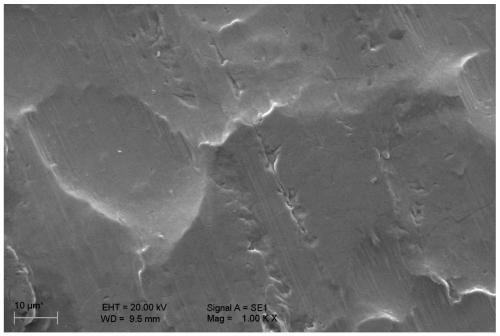

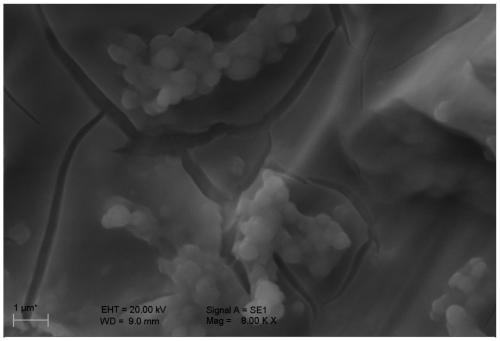

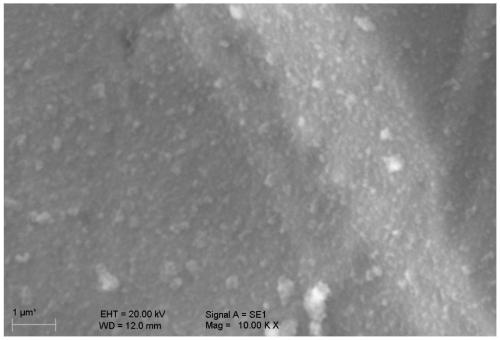

Image

Examples

Embodiment 1

[0071] A kind of alkaline silane rare earth doping treatment agent for metal surface treatment

[0072] 1. The raw materials include the following components formulated by weight percentage:

[0073]

[0074] Two, the preparation method is as follows:

[0075] Prepare according to the ratio of the above raw materials, first add water, then add triethanolamine, 3-aminopropyltrimethoxysilane, cerium nitrate, ethylene glycol, hydroxyethyl hexahydro-s-triazine, potassium citrate in turn under stirring . Fully stir and disperse evenly for half an hour, then test whether the pH is in the preferred range, if the pH is not in the required range, use an appropriate amount of NaOH to adjust the pH to 9.5, and the target product alkaline silane rare earth doping treatment agent can be obtained.

[0076] In actual use, the product is diluted with water at a weight ratio of 1:100 to obtain a usable alkaline silane treatment bath. The basic silane rare earth doping treatment agent in ...

Embodiment 2

[0078] A kind of alkaline silane rare earth doping treatment agent for metal surface treatment

[0079] 1. The raw materials include the following components formulated by weight percentage:

[0080]

[0081] Two, the preparation method is as follows:

[0082] Prepare according to the ratio of the above raw materials, first add water, then add triethanolamine, tetraethyl orthosilicate, 3-aminopropyltrimethoxysilane, cerium nitrate, ethylene glycol, hydroxyethyl hexahydro s-triazine, potassium citrate. Fully stir and disperse evenly for half an hour, then test whether the pH is in the preferred range, if the pH is not in the required range, use an appropriate amount of NaOH to adjust the pH to 9.5, and the target product alkaline silane rare earth doping treatment agent can be obtained.

[0083] In actual use, the product is diluted with water at a weight ratio of 1:100 to obtain a usable alkaline silane treatment bath. The basic silane rare earth doping treatment agent i...

Embodiment 3

[0085] A kind of alkaline silane rare earth doping treatment agent for metal surface treatment

[0086] 1. The raw materials include the following components formulated by weight percentage:

[0087]

[0088]

[0089] Two, the preparation method is as follows:

[0090] Prepare according to the ratio of the above raw materials, first add water, then add triethanolamine, glycidoxypropyltriethoxysilane, cerium nitrate, ethylene glycol, 1,2-benzisothiazole-3 - Ketones, Sodium Citrate. Fully stir and disperse evenly for half an hour, then test whether the pH is in the preferred range, if the pH is not in the required range, use an appropriate amount of NaOH to adjust the pH to 9.5, and the target product alkaline silane rare earth doping treatment agent can be obtained.

[0091] In actual use, the product is diluted with water at a weight ratio of 1:100 to obtain a usable alkaline silane treatment bath. The basic silane rare earth doping treatment agent in this embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com