Preparation method and application of bisphenol A electrochemical luminescence aptamer sensor

An aptamer sensor, electrochemical technology, applied in chemiluminescence/bioluminescence, electrochemical variables of materials, analysis by chemical reaction of materials, etc., to achieve the effect of improving stability, high sensitivity, and solving poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

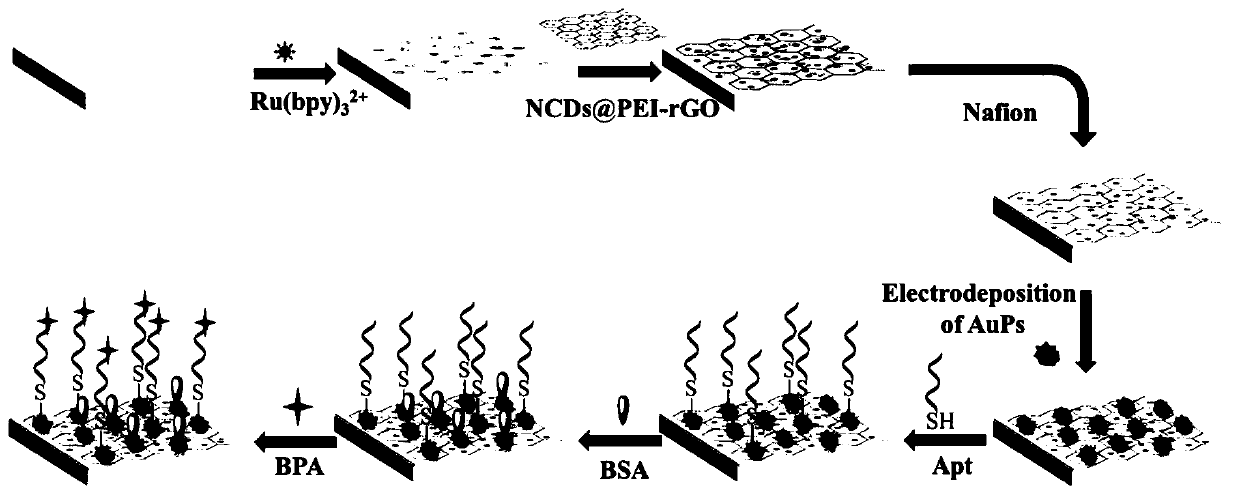

[0031] according to figure 1 Described preparation process:

[0032](1) Preparation of NCDs@PEI-reduced graphene oxide (rGO) composites

[0033] First, add 3g of citric acid, 3g of urea and 6g of polyethyleneimine (PEI) into 10mL of secondary water, react in an 800W microwave oven for 5min, and after cooling to room temperature, the obtained product is dissolved in secondary water again, at 12000rpm Centrifuge for 20min. The resulting upper layer solution was dialyzed in secondary water with a 50 kDa dialysis bag for three days and three nights to remove unreacted precursors. Finally, dry and concentrate in a vacuum oven at 60°C.

[0034] NCDs@PEI (2mg·mL) obtained above -1 ) was added to an equal volume of 2mg·mL -1 In rGO, mix ultrasound to prepare uniform NCDs@PEI-rGO (1mg mL -1 ), placed at room temperature for later use.

[0035] (2) The glassy carbon electrode (d=3mm GCE) was ground successively with 0.3 μm and 0.05 μm Al2O3 powder, and dried in air after ultrason...

Embodiment 2

[0045] (1) Preparation of NCDs@PEI-reduced graphene oxide (rGO) composites

[0046] First, add 3g of citric acid, 3g of urea and 6g of polyethyleneimine (PEI) into 10mL of secondary water, react in an 800W microwave oven for 5min, and after cooling to room temperature, the obtained product is dissolved in secondary water again, at 12000rpm Centrifuge for 20min. The resulting upper layer solution was dialyzed in secondary water with a 50 kDa dialysis bag for three days and three nights to remove unreacted precursors. Finally, dry and concentrate in a vacuum oven at 60°C.

[0047] NCDs@PEI (2mg·mL) obtained above -1 ) was added to an equal volume of 2mg·mL -1 In rGO, mixed with ultrasound to prepare uniform NCDs@PEI-rGO (1mg·mL -1 ), placed at room temperature for later use.

[0048] (2) The glassy carbon electrode (d=3mm GCE) was ground successively with 0.3 μm and 0.05 μm Al2O3 powder, and dried in air after ultrasonication in ethanol and water.

[0049] (3) 3 μL 0.5mmoL...

Embodiment 3

[0057] (1) Preparation of NCDs@PEI-reduced graphene oxide (rGO) composites

[0058] First, add 3g of citric acid, 3g of urea and 6g of polyethyleneimine (PEI) into 10mL of secondary water, react in an 800W microwave oven for 5min, and after cooling to room temperature, the obtained product is dissolved in secondary water again, at 12000rpm Centrifuge for 20min. The resulting upper layer solution was dialyzed in secondary water with a 50 kDa dialysis bag for three days and three nights to remove unreacted precursors. Finally, dry and concentrate in a vacuum oven at 60°C.

[0059] NCDs@PEI (2mg·mL) obtained above -1 ) was added to an equal volume of 2mg·mL -1 In rGO, mixed with ultrasound to prepare uniform NCDs@PEI-rGO (1mg·mL -1 ), keep at room temperature for later use.

[0060] (2) The glassy carbon electrode (d=3mm GCE) was ground successively with 0.3 μm and 0.05 μm Al2O3 powder, and dried in air after ultrasonication in ethanol and water.

[0061] (3) 3 μL 0.5mmoL·L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com