Rice enzymolysis protein powder with low granular sensation and preparation method and application of powder

A protein powder, grainy technology, applied in the field of rice protein, can solve the problems of high degree of hydrolysis, umami, bitter taste, etc., to achieve the effects of weak graininess, smooth protein taste, and improved sensitivity to enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

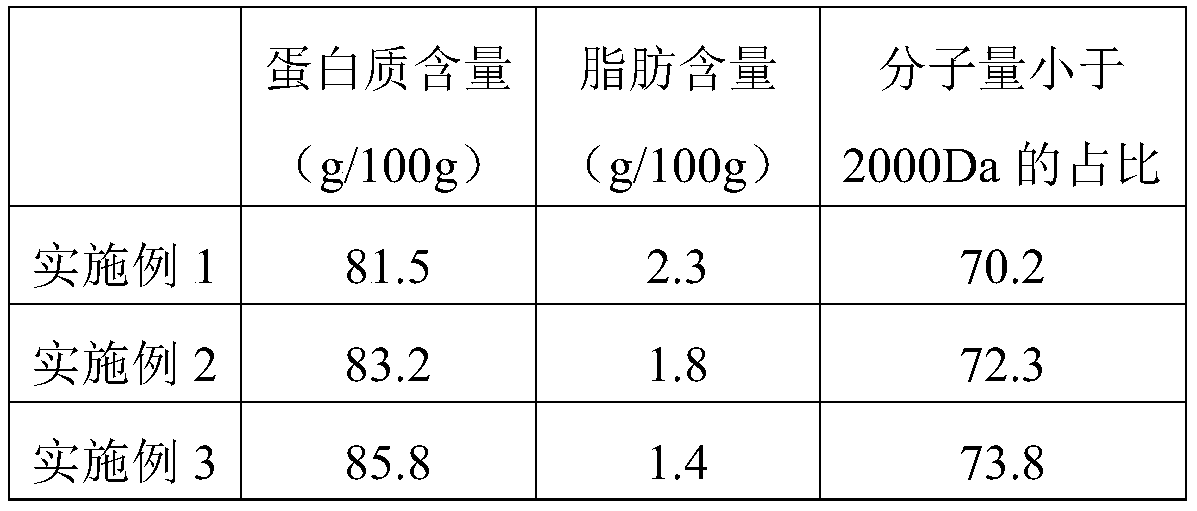

Examples

Embodiment 1

[0034] A rice enzymatic protein powder with low graininess, the preparation method of said rice enzymatic protein powder comprises the following steps:

[0035] (1) Pre-treatment of sugar-making rice dregs: using sugar-making rice dregs as the initial raw material, passing through a 40-mesh sieve to remove large particles of impurities;

[0036] (2) High-temperature extrusion pretreatment: add water to the rice dregs raw material obtained in step (1) to adjust the powder, adjust the moisture content to 20wt%, and carry out extrusion pretreatment on the material (the temperature of the inner cavity of the extruder is set to 130° C.);

[0037] (3) Refining treatment: use 10wt% NaOH aqueous solution to adjust the pH of the rice dregs feed liquid to 7.2, carry out solid-liquid separation of the feed liquid after alkali treatment and refinement, and obtain purified protein wet residue with a protein content higher than 80%;

[0038] (4) Wet crushing: the protein wet slag is slurrie...

Embodiment 2

[0045] A rice enzymatic protein powder with low graininess, the preparation method of said rice enzymatic protein powder comprises the following steps:

[0046] (1) Pre-treatment of sugar-making rice dregs: using sugar-making rice dregs as the initial raw material, passing through a 40-mesh sieve to remove large particles of impurities;

[0047](2) High-temperature extrusion pretreatment: add water to the rice dregs raw material obtained in step (1) to adjust the powder, adjust the moisture content to 15wt%, and carry out extrusion pretreatment on the material (the temperature of the inner cavity of the extruder is set to 150° C.);

[0048] (3) Refining treatment: use 10wt% lye (NaOH, NaOH 2 CO 3 1:1 mixing) to adjust the pH of the rice dregs feed liquid to 7.5, and separate the solid-liquid separation of the feed liquid after alkaline treatment to obtain purified protein wet residue with a protein content higher than 80%;

[0049] (4) Wet crushing: the protein wet slag is s...

Embodiment 3

[0056] A rice enzymatic protein powder with low graininess, the preparation method of said rice enzymatic protein powder comprises the following steps:

[0057] (1) Pre-treatment of sugar-making rice dregs: using sugar-making rice dregs as the initial raw material, passing through a 40-mesh sieve to remove large particles of impurities;

[0058] (2) High-temperature extrusion pretreatment: add water to the rice dregs raw material obtained in step (1) to adjust the powder, adjust the moisture content to 10wt%, and carry out extrusion pretreatment on the material (the temperature of the inner cavity of the extruder is set to 160° C.);

[0059] (3) Refining treatment: use 10wt% lye (NaOH, NaOH 2 CO 3 , NaHCO 3 1:1:1 compounding) to adjust the pH of the rice dregs feed liquid to 8.0, and separate the solid-liquid separation of the feed liquid after the alkali treatment to obtain purified protein wet dregs, the protein content of which is higher than 80%;

[0060] (4) Wet crushi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com