Composite film for guiding tissue repair and preparation method and application thereof

A technology to guide tissue and tissue repair, applied in medical science, prosthesis, etc., can solve problems such as difficult regeneration process, slow living process, cell shedding and death, etc., to improve protection effect, accelerate repair, and speed up repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

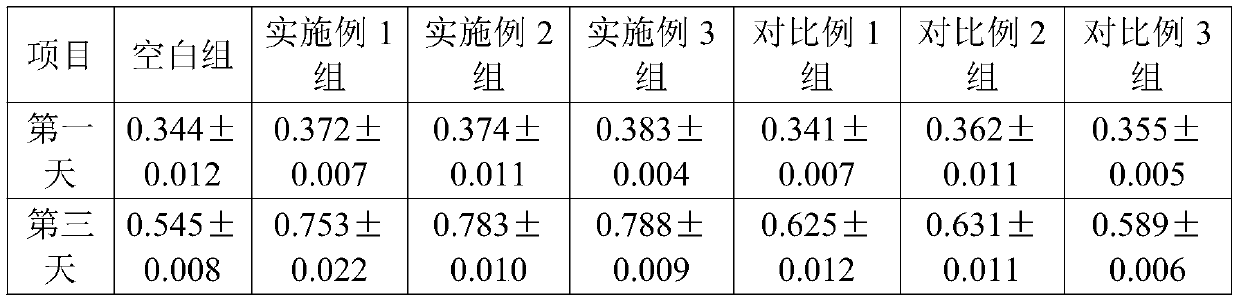

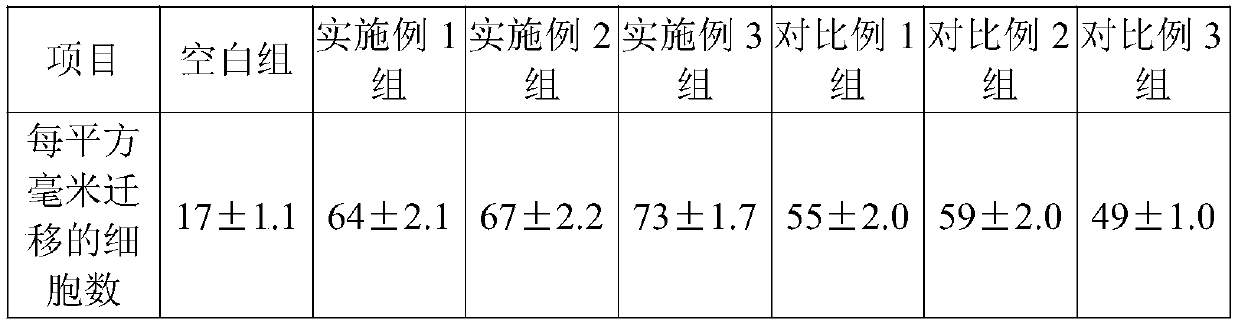

Examples

Embodiment 1

[0033] Example 1 A Composite Membrane for Guided Tissue Repair

[0034] A composite membrane that guides tissue repair, comprising a protective barrier layer made of chitosan and polyethylene glycol and a layer made of hyaluronic acid, sodium alginate, arginine-glycine-aspartame A tissue repair layer made of amino acid sequences and nano-microspheres that guides the growth of tissue cells.

[0035] The molecular weight of the polyethylene glycol is 4000Da.

[0036] The preparation method of the composite membrane for guiding tissue repair comprises the following steps:

[0037] S1 10mg chitosan is dissolved in 1% aqueous acetic acid solution by mass percentage to obtain a 1% chitosan solution by mass percentage, and 220 mg polyethylene glycol is dissolved in deionized water to obtain 22% polyethylene glycol by mass percentage. Diol solution, the resulting chitosan solution and polyethylene glycol solution were mixed and stirred for 24 hours to obtain a protective solution, w...

Embodiment 2

[0045] Example 2 A Composite Membrane for Guided Tissue Repair

[0046] A composite membrane that guides tissue repair, comprising a protective barrier layer made of chitosan and polyethylene glycol and a layer made of hyaluronic acid, sodium alginate, arginine-glycine-aspartame A tissue repair layer made of amino acid sequences and nano-microspheres that guides the growth of tissue cells.

[0047] The molecular weight of the polyethylene glycol is 8000Da.

[0048] The preparation method of the composite membrane for guiding tissue repair comprises the following steps:

[0049] S1 is that 30mg chitosan is dissolved in the acetic acid aqueous solution of 3% by mass percentage, is the chitosan solution of 3% by mass percentage, and 320mg polyethylene glycol is dissolved in deionized water, is the polyethylene glycol of 32% by mass percentage. Diol solution, the resulting chitosan solution and polyethylene glycol solution were mixed and stirred for 30 hours to obtain a protecti...

Embodiment 3

[0057] Example 3 A Composite Membrane for Guided Tissue Repair

[0058] A composite membrane that guides tissue repair, comprising a protective barrier layer made of chitosan and polyethylene glycol and a layer made of hyaluronic acid, sodium alginate, arginine-glycine-aspartame A tissue repair layer made of amino acid sequences and nano-microspheres that guides the growth of tissue cells.

[0059] The molecular weight of the polyethylene glycol is 6000Da.

[0060] The preparation method of the composite membrane for guiding tissue repair comprises the following steps:

[0061] S1 20mg chitosan is dissolved in 0.2% aqueous acetic acid solution by mass percentage to obtain a 2% chitosan solution by mass percentage, and 280 mg polyethylene glycol is dissolved in deionized water to obtain 28% polyethylene glycol by mass percentage. Diol solution, the resulting chitosan solution and polyethylene glycol solution were mixed and stirred for 28 hours to obtain a protective solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com