Preparation method and application of multifunctional PCS hybridized nanometer fiber biomedical elastomer

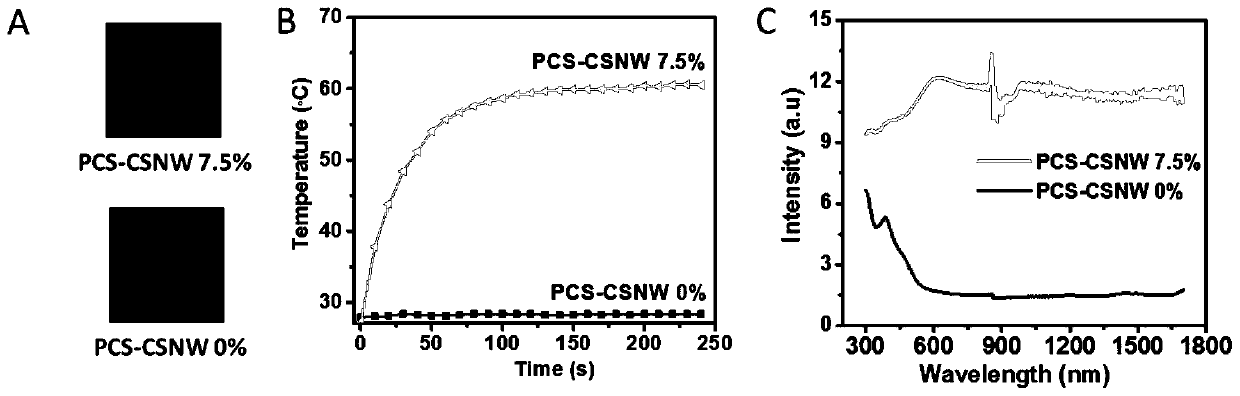

A nanofiber and biomedical technology, which is applied in the field of preparation of multifunctional PCS hybrid nanofiber biomedical elastomers, can solve the problems of no anti-microbial infection ability, few functions, no photothermal ability and photothermal treatment, etc. Achieve the effect of good monomer biocompatibility and strong photothermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] 1) Preparation of PCS prepolymer: Add citric acid and 1,8-octanediol at a molar ratio of 1:1 into a 50mL round-bottomed flask, conduct thermal polymerization in an oil bath at 160°C under the protection of nitrogen, and wait for all to melt Finally, after adding (3-aminopropyl)triethoxysilane, cool down to 140°C and react for 2 hours; the product is purified in deionized water, freeze-dried and retained;

[0044] 2) Preparation of CSNW nanofibers: First, 1.0 mmol of cuprous (I) chloride (CuCl) and 10.0 ml of oleylamine (OM) were added to a three-necked flask (50 mL) at room temperature, and heated in vacuum to 130°C to remove oxygen and water. At the same time, 2.5 mmol of sodium diethyldithiocarbamate (NaDDTC) was dispersed in 6.0 ml of OM by ultrasonic waves, injected into the CuCl / OM solution at 260 °C, and then the mixture was kept at 260 °C for 15 min, the color It is gray-black. The precipitate (CSNW) was collected by centrifugation at 8500 rpm for 10 min and wa...

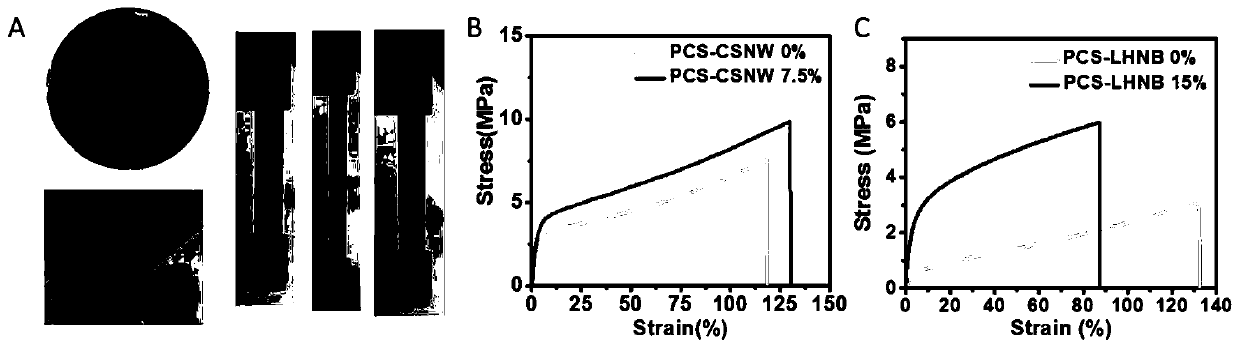

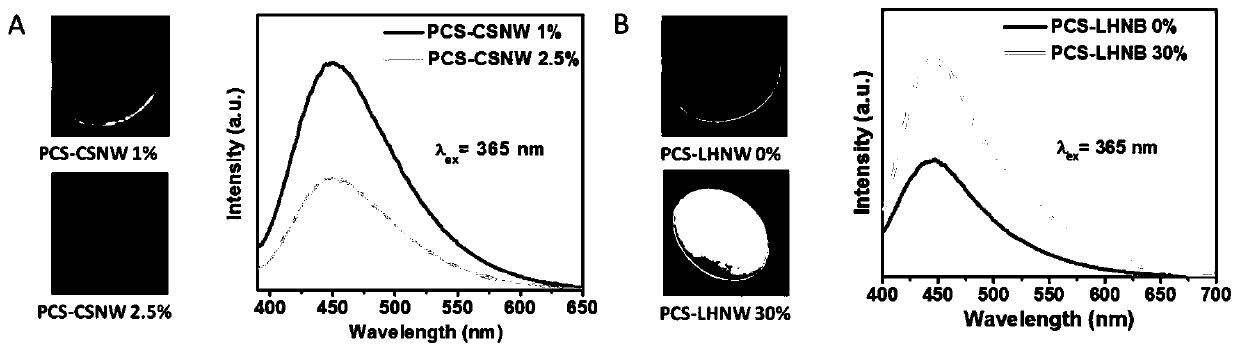

Embodiment 1

[0058] 1) Preparation of PCS prepolymer: citric acid with a total mass of 6g, 1,8-octanediol and (3-aminopropyl) triethoxysilane according to 1:1:0.4, first citric acid and 1, Add 8-octanediol into a 50mL round-bottomed flask, stir it under nitrogen atmosphere and put it into an oil bath at 160°C to melt; after it is completely melted, immediately lower the temperature to 140°C, add (3-aminopropyl)triethoxy Silane, reacted under nitrogen atmosphere for 2h. The reaction product was dissolved in DMSO, purified by dialysis in deionized water for 2 days, and freeze-dried for later use;

[0059] 2) Preparation of CSNW nanofibers: First, 1.0 mmol of cuprous (I) chloride (CuCl) and 10.0 ml of oleylamine (OM) were added to a three-necked flask (50 mL) at room temperature, and heated in vacuum to 130°C to remove oxygen and water. At the same time, 2.5 mmol of sodium diethyldithiocarbamate (NaDDTC) was dispersed in 6.0 ml of OM by ultrasonic waves, injected into the CuCl / OM solution a...

Embodiment 2

[0062] 1) Preparation of PCS prepolymer: citric acid with a total mass of 6g, 1,8-octanediol and (3-aminopropyl) triethoxysilane according to 1:1:0.4, first citric acid and 1, Add 8-octanediol into a 50mL round-bottomed flask, stir it under nitrogen atmosphere and put it into an oil bath at 160°C to melt; after it is completely melted, immediately lower the temperature to 140°C, add (3-aminopropyl)triethoxy Silane, reacted under nitrogen atmosphere for 2h. The reaction product was dissolved in DMSO, purified by dialysis in deionized water for 2 days, and freeze-dried for later use;

[0063] 2) Preparation of CSNW nanofibers: First, 1.0 mmol of cuprous (I) chloride (CuCl) and 10.0 ml of oleylamine (OM) were added to a three-necked flask (50 mL) at room temperature, and heated in vacuum to 130°C to remove oxygen and water. At the same time, 2.5 mmol of sodium diethyldithiocarbamate (NaDDTC) was dispersed in 6.0 ml of OM by ultrasonic waves, injected into the CuCl / OM solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com