Preparation method and application of oil tea fruit shell activated carbon

A technology of camellia husk and activated carbon, which is applied in chemical instruments and methods, textile industry wastewater treatment, inorganic chemistry and other directions, can solve the problems of increased production cost of activated carbon, high corrosion of equipment and high energy consumption of activated carbon, and achieves clean production, The effect of long service life and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

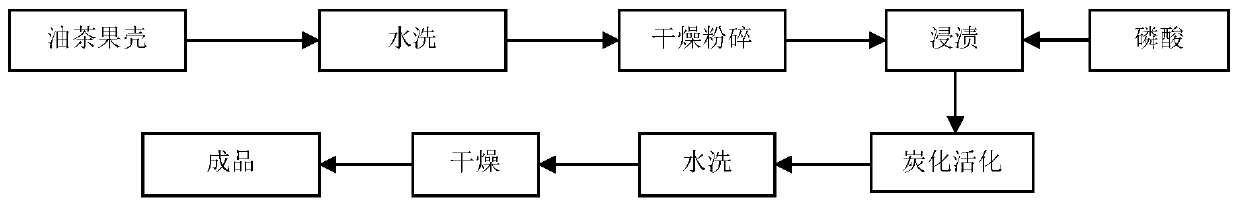

[0036] A preparation method of camellia oleifera husk activated carbon, comprising the following steps:

[0037] (1) the camellia oleifera shell is washed, dried, pulverized and sieved to obtain the camellia oleifera shell powder for subsequent use;

[0038] (2) impregnating the camellia oleifera shell powder prepared in step (1) and the phosphoric acid solution with a concentration of 50-70wt% in a mass ratio of 1:2-4, wherein the impregnating time is 4-18h;

[0039] (3) Place the material obtained in step (2) in a high-temperature box furnace, and heat it from room temperature to a final temperature of 400-650°C under vacuum conditions, carbonize and activate simultaneously, keep warm, stop heating, and naturally cool to room temperature;

[0040] (4) Soak the product obtained in step (3) with deionized water, and repeatedly rinse until neutral; after washing, put it into a drying box for drying, and pulverize after drying to obtain the camellia oleifera husk activated carbo...

Embodiment 1

[0043] A preparation method of camellia oleifera husk activated carbon, comprising the following steps:

[0044] (1) the camellia oleifera shell is washed, dried, pulverized, and passed through a 100-mesh sieve to obtain the camellia oleifera shell powder for subsequent use;

[0045] (2) impregnating the camellia oleifera shell powder and phosphoric acid with a concentration of 50wt% in a mass ratio of 1:2 for 12h;

[0046] (3) Heat the impregnated Camellia oleifera shell powder in a high-temperature box furnace under reduced pressure from room temperature to 550° C. for 1 hour, keep it warm for a period of time; stop heating, and naturally cool to room temperature;

[0047] (4) Soak the product obtained in step (3) with deionized water, and repeatedly rinse until neutral; after washing, put it into a drying box for drying, and pulverize after drying to obtain the camellia oleifera husk activated carbon;

[0048] (5) The camellia oleifera husk activated carbon prepared in step ...

Embodiment 2

[0050] Change the mass ratio of Camellia oleifera husk powder and phosphoric acid solution into 1:3 in embodiment 1, and all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

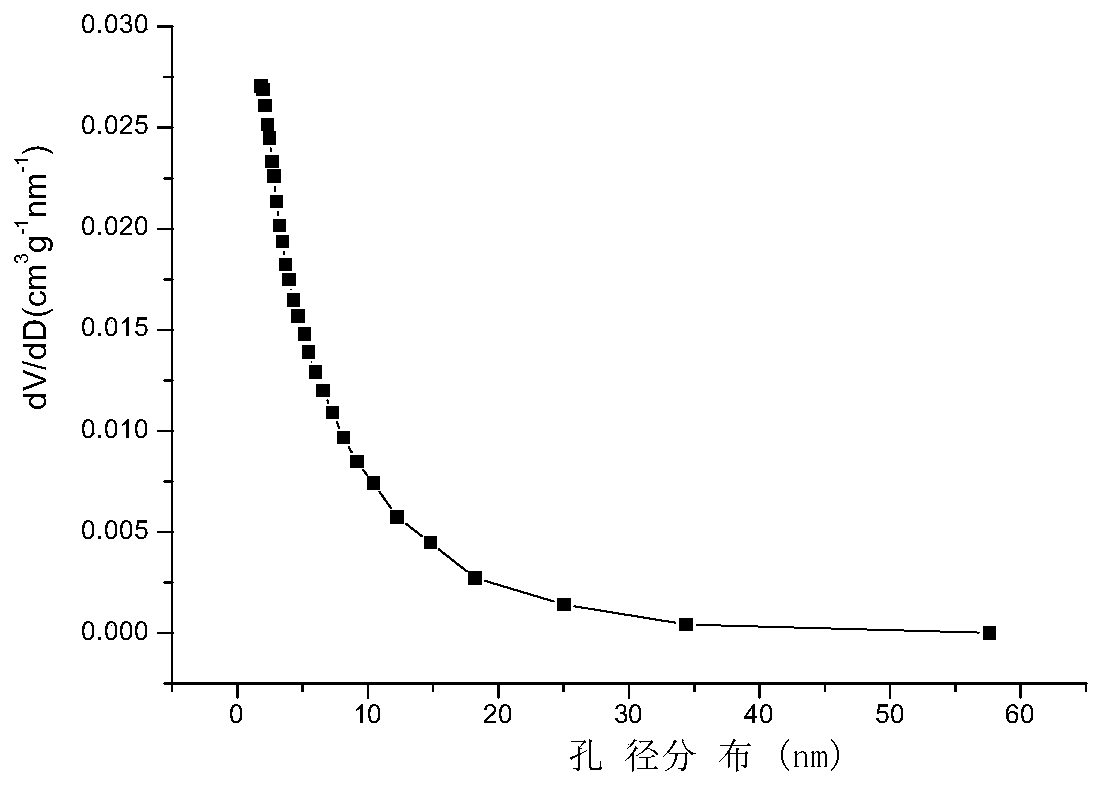

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com