Preparation method of high-frequency noise-reduction asphalt

A technology of noise reduction and asphalt, applied in building components, building insulation materials, buildings, etc., can solve the problems of noise reduction performance and noise reduction aging that cannot be further improved, improve high-frequency noise reduction, facilitate distribution, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

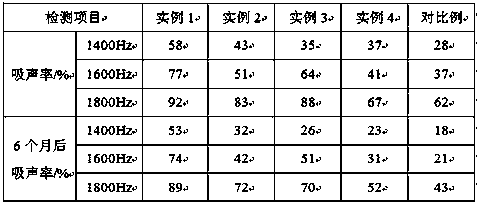

Examples

example 1

[0027] Mix potassium carbonate and titanium dioxide in a grinder at a molar ratio of 1.5:4.0, mix and grind for 25 hours to obtain a mixed powder, and then calcinate the mixed powder at a temperature of 850°C for 20 hours at a constant temperature to obtain a potassium tetratitanate powder blank. Wash the potassium tetratitanate powder blank with 18% hydrochloric acid for 8 times, and dry it at 90°C for 2 hours to obtain potassium tetratitanate powder; add lignosulfonic acid with a mass fraction of 18% Sodium solution and formaldehyde are mixed in a beaker at a mass ratio of 30:1, and sodium sulfite, which is 3 times the mass of formaldehyde, is added to the beaker, and stirred and reacted for 2 hours at a temperature of 70°C and a speed of 400r / min to obtain pretreated wood Sodium sulfonate solution, mix the pretreated sodium lignosulfonate solution and potassium iodide in a three-necked flask at a mass ratio of 120:1, and add 0.3 times the mass fraction of the pretreated sodi...

example 2

[0029]Mix the sodium lignosulfonate solution with a mass fraction of 18% and formaldehyde in a beaker at a mass ratio of 30:1, and add sodium sulfite three times the mass of formaldehyde to the beaker, at a temperature of 70°C and a speed of 400r / min After stirring and reacting for 2 hours under the same conditions, the pretreated sodium lignosulfonate solution was obtained. The pretreated sodium lignosulfonate solution and potassium iodide were mixed in a three-necked flask at a mass ratio of 120:1, and the pretreated lignin was added to the three-necked flask. 0.3 times the mass fraction of sodium sulfonate solution is 90% 1,6-dibromohexane ethanol solution, control the addition rate of 1,6-dibromohexane ethanol solution to 8mL / min, and use a mass fraction of 12 % sodium hydroxide solution to control the pH of the material in the three-necked flask to 12, and after stirring and reacting for 4 hours at a temperature of 80°C and a rotation speed of 380r / min, a treatment agent m...

example 3

[0031] Mix potassium carbonate and titanium dioxide in a grinder at a molar ratio of 1.5:4.0, mix and grind for 25 hours to obtain a mixed powder, and then calcinate the mixed powder at a temperature of 850°C for 20 hours at a constant temperature to obtain a potassium tetratitanate powder blank. Wash the potassium tetratitanate powder blank with 18% hydrochloric acid for 8 times, and dry it at 90°C for 2 hours to obtain potassium tetratitanate powder; add lignosulfonic acid with a mass fraction of 18% Sodium solution and formaldehyde are mixed in a beaker at a mass ratio of 30:1, and sodium sulfite, which is 3 times the mass of formaldehyde, is added to the beaker, and stirred and reacted for 2 hours at a temperature of 70°C and a speed of 400r / min to obtain pretreated wood Sodium sulfonate solution, mix the pretreated sodium lignosulfonate solution and potassium iodide in a three-necked flask at a mass ratio of 120:1, and add 0.3 times the mass fraction of the pretreated sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com