High-precision electronics PUR (polyurethane resin) hot melt glue and preparation method thereof

A high-precision, hot-melt adhesive technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as degumming of plastic casings or circuit boards, expensive imported products, and poor universality. Achieving the effect of moderate price, outstanding low temperature resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

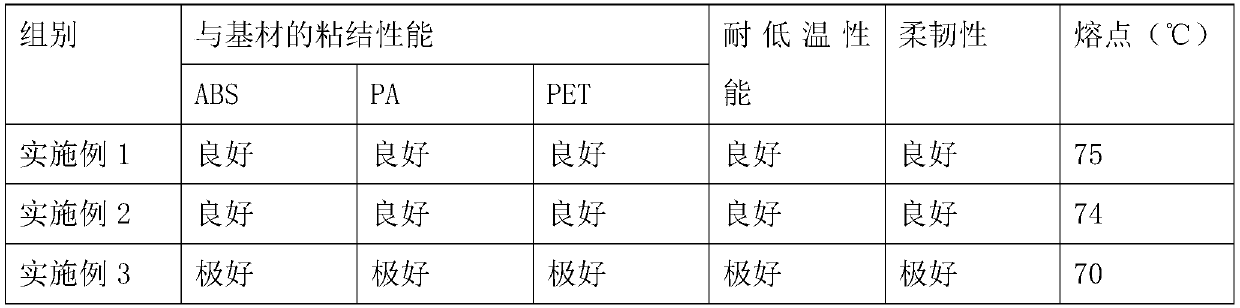

Examples

Embodiment 1

[0022] A PUR hot melt adhesive for high-precision electronics, its raw materials include isocyanate, synthetic resin and catalyst;

[0023] The synthetic resin is prepared from polyols and long-chain dibasic acids at 140° C. for 3 hours, and the mass ratio of polyols to dibasic acids is 100:75. The synthetic resin has a molecular weight of 1000-5000 and a functionality of 1.5. The polyhydric alcohol is 1,2 propanediol.

[0024] The isocyanate is toluene diisocyanate (TDI), and the total mole number of isocyanate is 1.01 times of the total mole number of hydroxyl groups.

[0025] A preparation method of PUR hot melt adhesive for high-precision electronics, prepared according to the following method:

[0026] S1. Synthetic resin and TDI are placed in the prepolymerization reactor, be heated to 40 ℃, after stirring while reacting for 1 hour, cooling, stirring does not stop during cooling, makes prepolymer; Described isocyanate is TDI (toluene Diisocyanate), the total number of...

Embodiment 2

[0029] A PUR hot melt adhesive for high-precision electronics, its raw materials include isocyanate, synthetic resin and catalyst;

[0030] The synthetic resin is prepared by reacting polyols and long-chain dibasic acids at 240° C. for 18 hours, and the mass ratio of polyols to dibasic acids is 100:225. The synthetic resin has a molecular weight of 1000-5000 and a functionality of 4. The polyol is trimethylolpropane.

[0031] The isocyanate is diphenylmethane diisocyanate (MDI), and the total mole number of the isocyanate is twice the total mole number of hydroxyl groups.

[0032] A preparation method of PUR hot melt adhesive for high-precision electronics, prepared according to the following method:

[0033] S1. Put synthetic resin, MDI, and chain extender in a prepolymerization reactor, heat to 150°C, react while stirring for 12 hours, then cool, and stir without stopping during cooling to obtain a prepolymer; The chain agent is 1,4 butanediol. The isocyanate is MDI (dip...

Embodiment 3

[0036] A PUR hot melt adhesive for high-precision electronics, its raw materials include isocyanate, synthetic resin and catalyst;

[0037] The synthetic resin is prepared by reacting polyols and long-chain dibasic acids at 200° C. for 10 hours, and the mass ratio of polyols to dibasic acids is 100:125. The synthetic resin has a molecular weight of 1000-5000 and a functionality of 2.5. The polyhydric alcohol is trimethylolpropane, and the dosage is 1% of the total moles of hydroxyl groups.

[0038] The isocyanate is hexamethylene diisocyanate (HDI), and the total mole number of the isocyanate is 1.5 times of the total mole number of hydroxyl groups.

[0039] A preparation method of PUR hot melt adhesive for high-precision electronics, prepared according to the following method:

[0040] S1. Put synthetic resin, HDI, and chain extender in a prepolymerization reactor, heat to 100°C, react while stirring for 6 hours, then cool, and stir without stopping during cooling to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com