An organic-inorganic composite silicate high temperature resistant film-forming drilling fluid system

A composite silicate and organosilicate technology, applied in the field of drilling fluid, to achieve uniform film formation, good filtration loss reduction, and the effect of satisfying the well wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

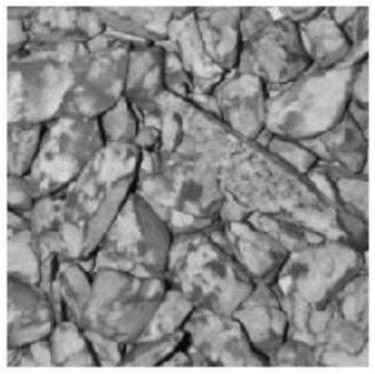

[0035] Example 1: The organic-inorganic composite silicate high temperature resistant film-forming drilling fluid system in this example contains methyl silicate with a concentration of 0.2mol / L and silicate C with a concentration of 0.06mol / L, and is prepared by the following steps Obtained: Add weighed methyl silicate and silicate C into 300mL of distilled water, stir magnetically for 20min, put them into a high-temperature reactor with 40g of cuttings, react at 180°C for 16h, and dry Weigh its quality after treatment, and observe the filming phenomenon on the surface of cuttings, see figure 1 .

Embodiment 2

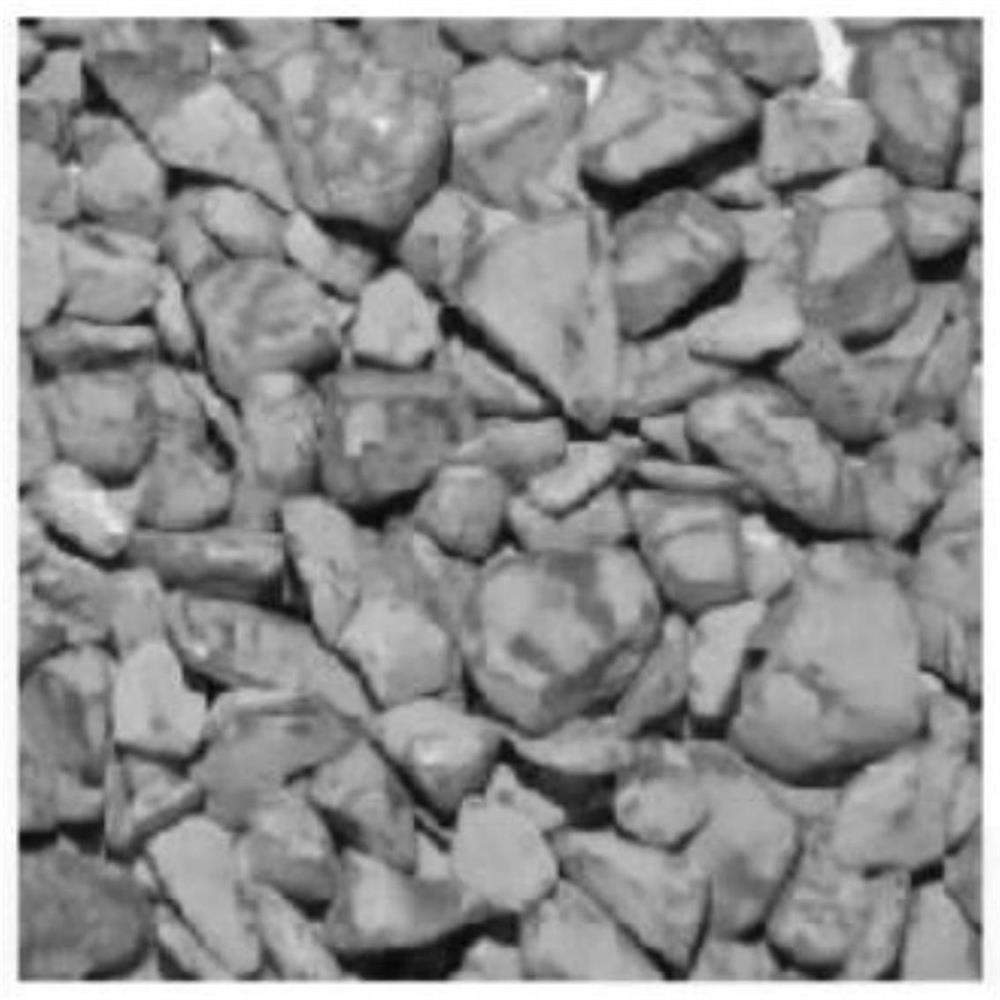

[0036] Example 2: The organic-inorganic composite silicate high temperature resistant film-forming drilling fluid system in this example contains 2% organosilane by mass fraction and 1% silicate D by mass fraction, and is prepared by the following steps: Add the weighed organosilane and silicate D into 300mL of distilled water, stir magnetically for 20min, put it into a high-temperature reaction kettle with 40g of cuttings, react at 180°C for 16h, and weigh it after drying , and observe the film formation phenomenon on the surface of cuttings, see figure 2 .

Embodiment 3

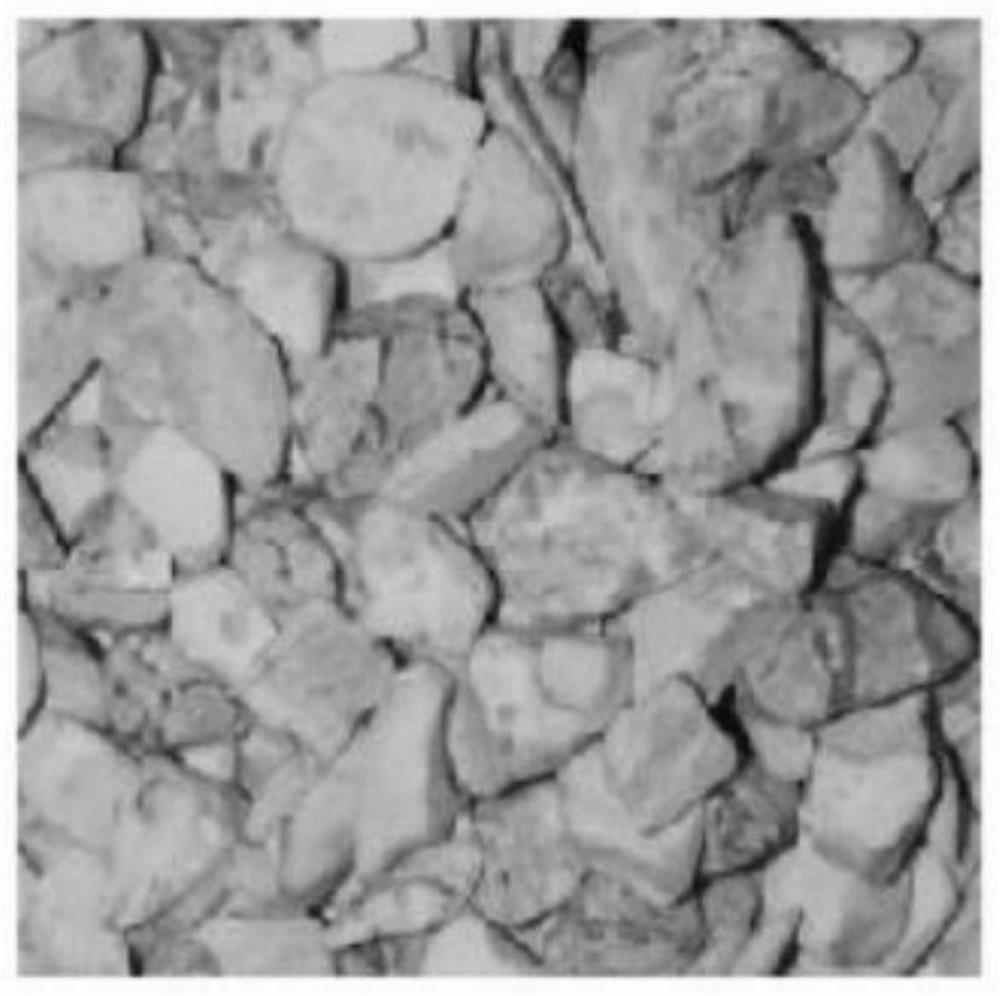

[0037] Example 3: The organic-inorganic composite silicate high temperature resistant film-forming drilling fluid system in this example contains methyl silicate with a concentration of 0.2mol / L and silicate C with a concentration of 0.06mol / L, and is prepared by the following steps Obtained: Add weighed methyl silicate A and silicate C into 300mL of distilled water, stir magnetically for 20min, put them into a high-temperature reaction kettle with 40g of cuttings, react at 220°C for 16h, bake Weigh its mass after dry treatment, and observe the film formation phenomenon on the surface of cuttings, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com