Assembly type light steel passive house with near zero energy consumption

A prefabricated and passive house technology, applied in passive houses, heating methods, lighting and heating equipment, etc., can solve problems such as poor air tightness, inability to guarantee temperature, and large exchange of hot and cold air, so as to reduce energy consumption and improve The effect of thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

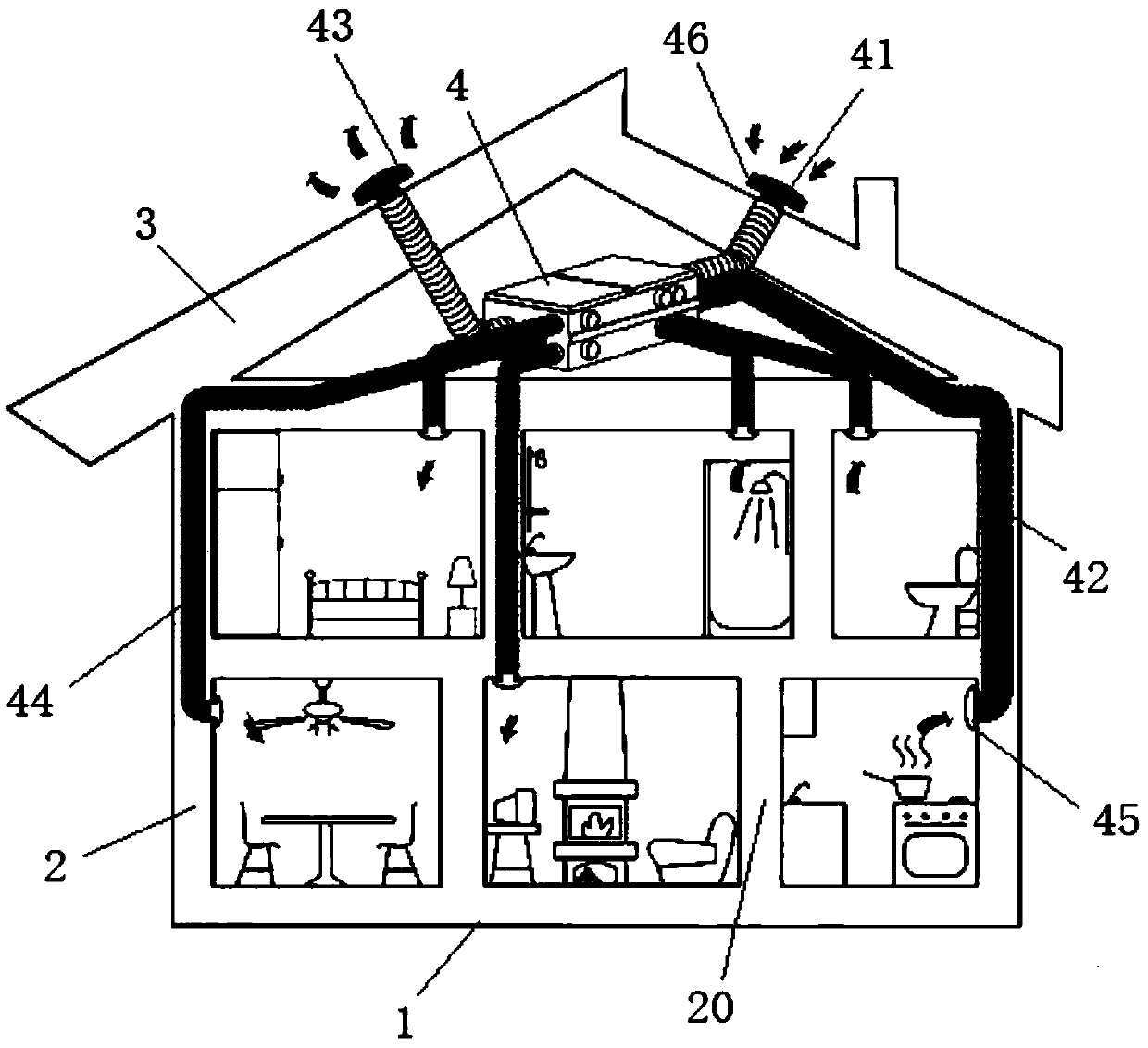

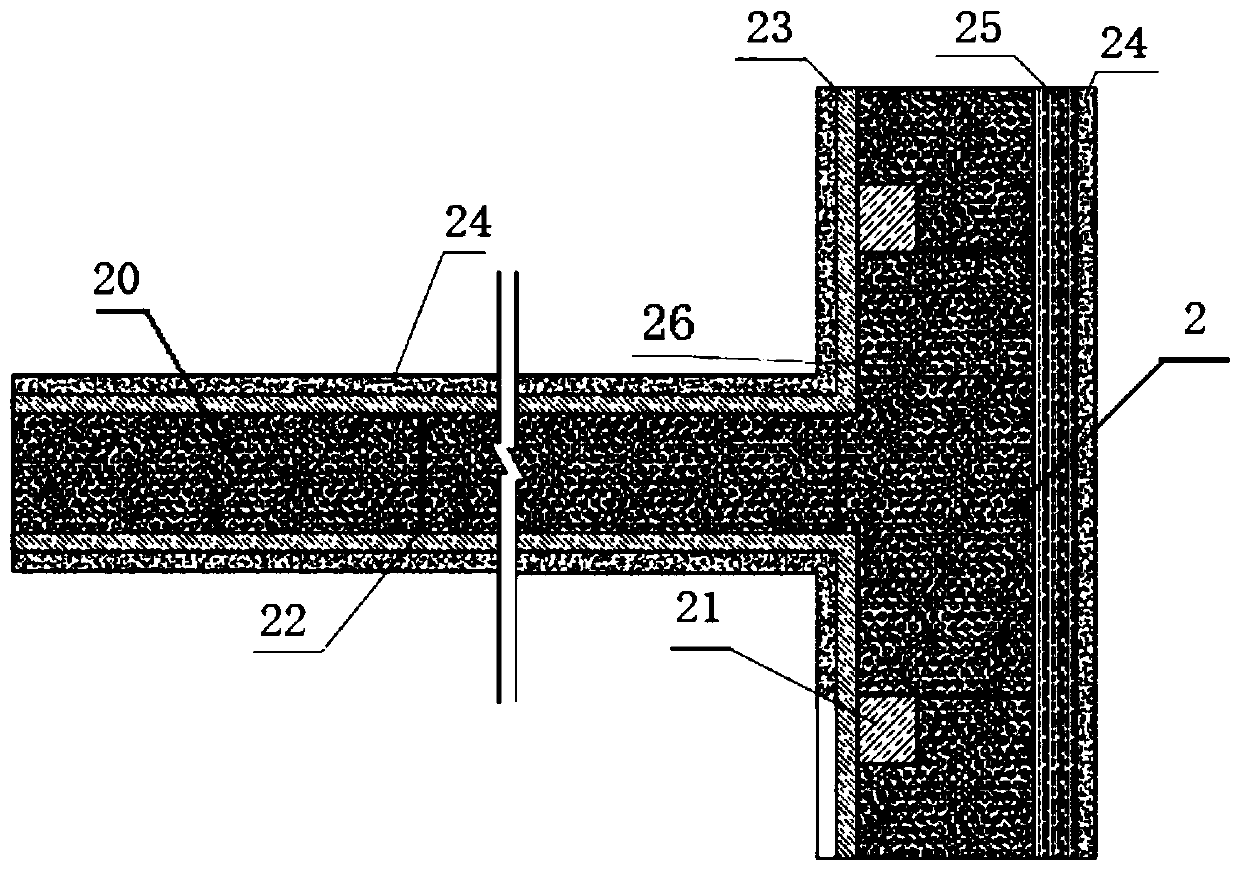

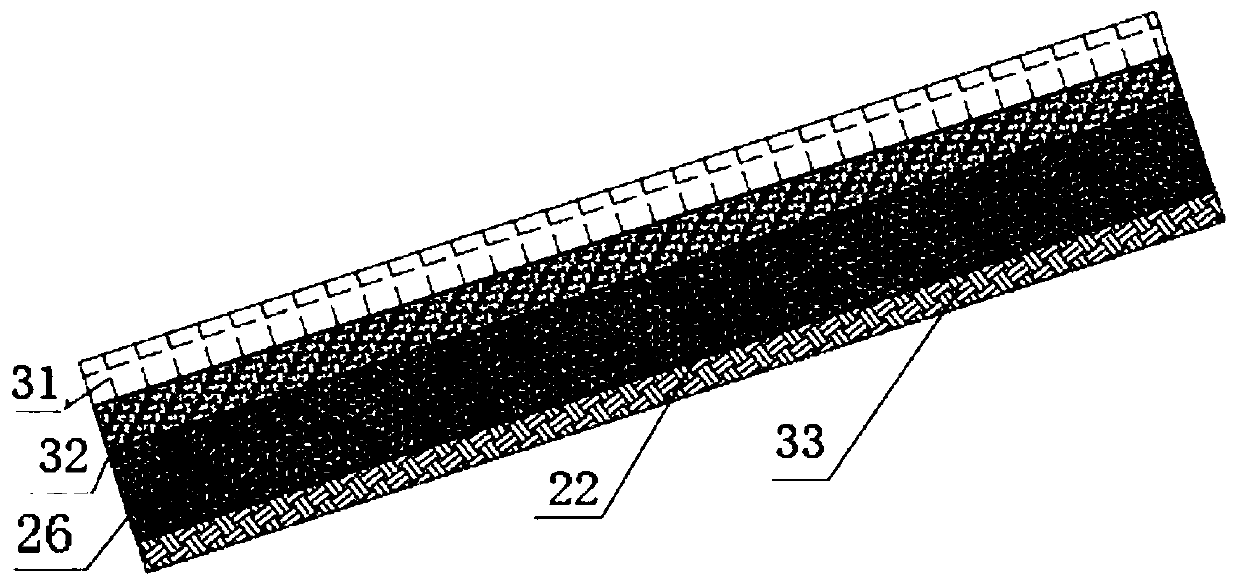

[0027] Example 1 as Figure 1 to Figure 3 As shown, the low energy consumption prefabricated light steel passive house of this embodiment includes: a house body composed of an indoor ground 1, a wall, and a roof 3, and the wall includes a multi-faceted inner wall 20 and a multi-faced outer wall 2 for Multiple independent indoor spaces are isolated, including bedrooms, guest rooms, restaurants, toilets, washrooms, kitchens, etc. The prefabricated light steel passive house also includes a fresh air full heat exchange system, which includes heat exchangers 4, Air supply air inlet duct 41, a plurality of air supply air outlet ducts 44, a plurality of exhaust air inlet ducts 42, exhaust air outlet ducts 43, the heat exchanger 4 communicates with the outside of the house body through the air supply air inlet duct 41, with For the introduction of outdoor fresh air, the heat exchanger 4 communicates with each indoor space through the air supply duct 44, and is used to send fresh air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com