Preparing method for graphite composite film

A composite film and graphite technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of uneven thickness, rough surface, reduce the applicability of graphite composite film, etc., to improve the specific capacitance effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

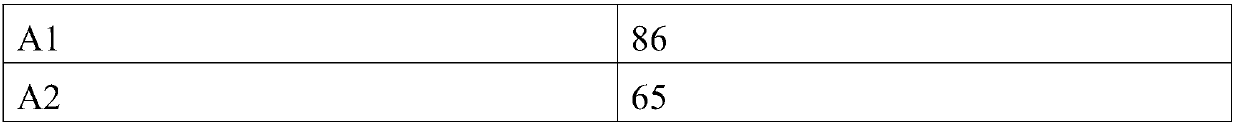

[0023] The present invention provides a preparation method of a graphite composite membrane, comprising providing a zeolite suspension and a graphite suspension, the graphite suspension comprising graphite oxide; reducing the graphite suspension to reduce the graphite oxide to form partially reduced graphite, Then add the zeolite suspension and a surfactant to form a mixed solution, and then reduce the mixed solution to completely reduce the part of the reduced graphite to form graphite, and then use the electrode aerosol deposition method to form the mixed solution on a substrate. A graphite composite film.

[0024] Specifically, the zeolite suspension contains nano zeolite particles with a particle diameter of 90-180 nm, and the concentration may be 250-300 ppm. The zeolite suspension can be prepared by conventional methods. In addition, the pH value of the zeolite suspension can be 11-13 under general manufacturing process. For example, the nano-zeolite particles can be s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com