Environmental protecting, fireproofing, heat preserving and heat insulating and decorating integrated rubbing imitated wood product and preparation method thereof

A technology for thermal insulation and wood products, applied in the fields of fire prevention, decoration integrated rubbing imitation wood products and their preparation, thermal insulation, environmental protection, can solve the problems of long production cycle, poor thermal insulation effect, etc. Low cost, fewer steps, and the effect of reducing the amount of laying labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

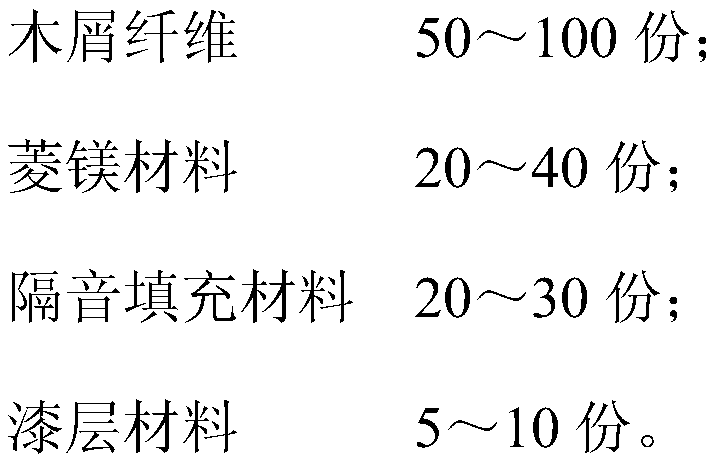

[0029] An environmental-friendly, fireproof, thermal insulation, and decorative rubbing imitation wood product, which is composed of the following materials in parts by weight:

[0030]

[0031]

[0032] Further, the sawdust fiber is crushed sawdust with a particle size of 50 mesh.

[0033] Further, the components of the magnesite material are magnesium oxide and magnesium chloride hexahydrate, and the mass ratio is 1:1.

[0034] Further, the sound-insulating filling material is a fibrous porous sound-insulating material.

[0035] Further, the combination of one or more of the sound-insulating filling materials polyester fiber sound-insulating cotton, centrifugal glass wool, rock wool, and mineral wool, most of these materials also have a certain heat preservation effect, so together with the air thermal resistance, Get better insulation effect.

[0036] The preparation method of a kind of environmental protection, fire prevention, thermal insulation, decoration integr...

Embodiment 2

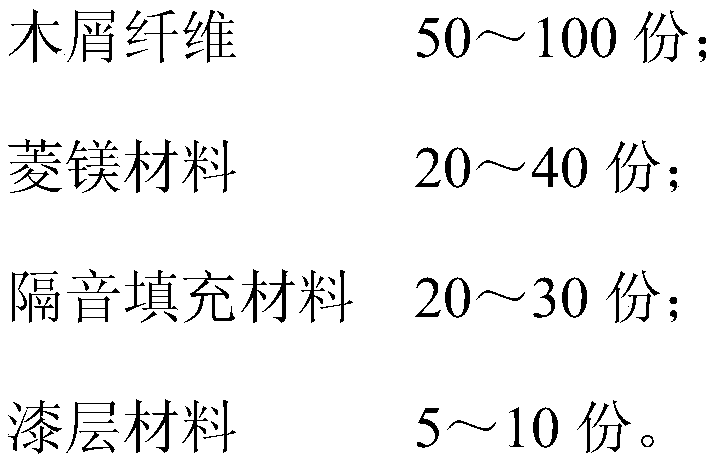

[0043] An environmental-friendly, fireproof, thermal insulation, and decorative rubbing imitation wood product, which is composed of the following materials in parts by weight:

[0044]

[0045] Further, the sawdust fiber is crushed sawdust with a particle size of 150 mesh.

[0046] Further, the components of the magnesite material are magnesium oxide and magnesium chloride hexahydrate, with a mass ratio of 1:1.5.

[0047] Further, the sound-insulating filling material is a fibrous porous sound-insulating material.

[0048] Further, the sound-insulating filling material is a combination of one or more of polyester fiber sound-insulating wool, centrifugal glass wool, rock wool, and mineral wool.

[0049] The preparation method of a kind of environmental protection, fire prevention, thermal insulation, decoration integrated rubbing imitation wood products, comprises the following steps:

[0050] S1, distributing the sound-insulating filling material in the mould, so that th...

Embodiment 3

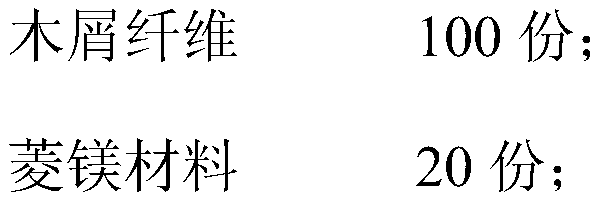

[0056] An environmental-friendly, fireproof, thermal insulation, and decorative rubbing imitation wood product, which is composed of the following materials in parts by weight:

[0057]

[0058] Further, the wood chip fiber is crushed wood chip with a particle size of 200 mesh.

[0059] Further, the components of the magnesite material are magnesium oxide and magnesium chloride hexahydrate, with a mass ratio of 1:1.2.

[0060] Further, the sound-insulating filling material is a fibrous porous sound-insulating material.

[0061] Further, the sound-insulating filling material is a combination of one or more of polyester fiber sound-insulating wool, centrifugal glass wool, rock wool, and mineral wool.

[0062] The preparation method of a kind of environmental protection, fire prevention, thermal insulation, decoration integrated rubbing imitation wood products, comprises the following steps:

[0063] S1, distributing the sound-insulating filling material in the mould, so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com