Method for extracting selenium from selenium-containing anode mud through oxygen-enriched boiling roasting-organic reduction

A technology of boiling roasting and anode slime, which is applied in the field of non-ferrous metal metallurgy, can solve the problems of selenium-containing anode slime that is not very clean and efficient, simple to operate, and achieves simple operation, clean process, high purity and direct yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

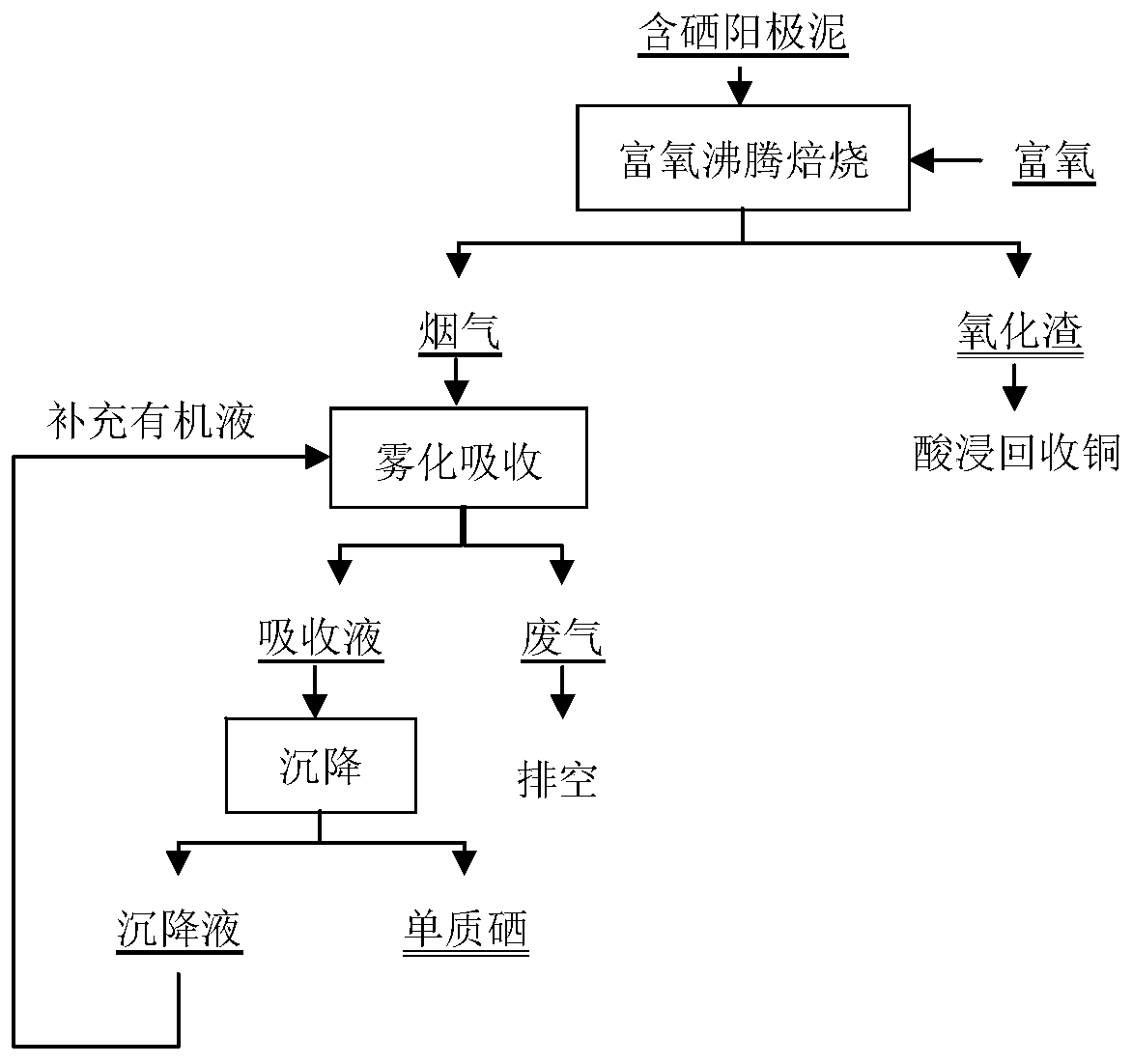

[0052] This embodiment provides a method for extracting selenium from selenium-containing anode mud by oxygen-enriched boiling roasting and organic reduction. The process flow chart is as attached figure 1 As shown, it specifically includes the following steps:

[0053] S1. Weigh 1000g of selenium-containing anode slime with the above ingredients, finely grind them to pass -60 mesh screen, put them into a boiling furnace, heat up to 800℃, and blow in 60% concentration at a linear velocity of 1.5m / s Oxygen-enriched air was roasted for 2.0 hours. After the reaction, a selenium-containing flue gas and a roasting slag composed of a large amount of copper oxide were obtained. The weight of the roasting slag was weighed to be 1014.27g, and the copper content was 44.11%. The calculated copper yield was 97.41. %;

[0054] S2. Turn on the exhaust and atomization devices at the same time, pass the selenium-containing flue gas obtained in step S1 into the absorption chamber, and spray an etha...

Embodiment 2

[0057] This embodiment provides a method for extracting selenium from selenium-containing anode mud by oxygen-enriched boiling roasting and organic reduction. The process flow chart is as attached figure 1 As shown, the atomization liquid of the present invention is the post-selenium precipitation liquid of Example 1, and new ethanol is added to make the concentration reach 35%. It includes the following steps:

[0058] S1. Weigh 1000g of selenium-containing anode slime with the above components, finely grind them to pass through a -100 mesh screen, put them into a boiling furnace, heat up to 850℃, and blow in a concentration of 60% at a linear velocity of 2.5m / s The oxygen-enriched air was roasted for 2.0h. After the reaction, the selenium-containing flue gas and a roasting slag composed of a large amount of copper oxide were obtained. The weight of the roasting slag was weighed to be 1013.44g, and the copper content was 42.68%. The direct yield of copper was calculated 94.17%; ...

Embodiment 3

[0062] This embodiment provides a method for extracting selenium from selenium-containing anode mud by oxygen-enriched boiling roasting and organic reduction. The process flow chart is as attached figure 1 As shown, it specifically includes the following steps:

[0063] S1. Weigh 1000g of the selenium-containing anode slime with the above components, finely grind them until they all pass through a -60 mesh screen, put them into a boiling furnace, heat up to 700°C, and blow in a concentration of 50% at a linear velocity of 1.5m / s The oxygen-enriched air is roasted for 2.0h. After the reaction, a roasting slag composed of a large amount of copper oxide and selenium-containing flue gas is obtained. The weighing of the roasting slag is 1032.14g, and the copper content is 43.75%. The copper direct yield is calculated 98.32%;

[0064] S2. Turn on the ventilation and atomization devices at the same time, pass the selenium-containing flue gas obtained in step S1 into the absorption chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com