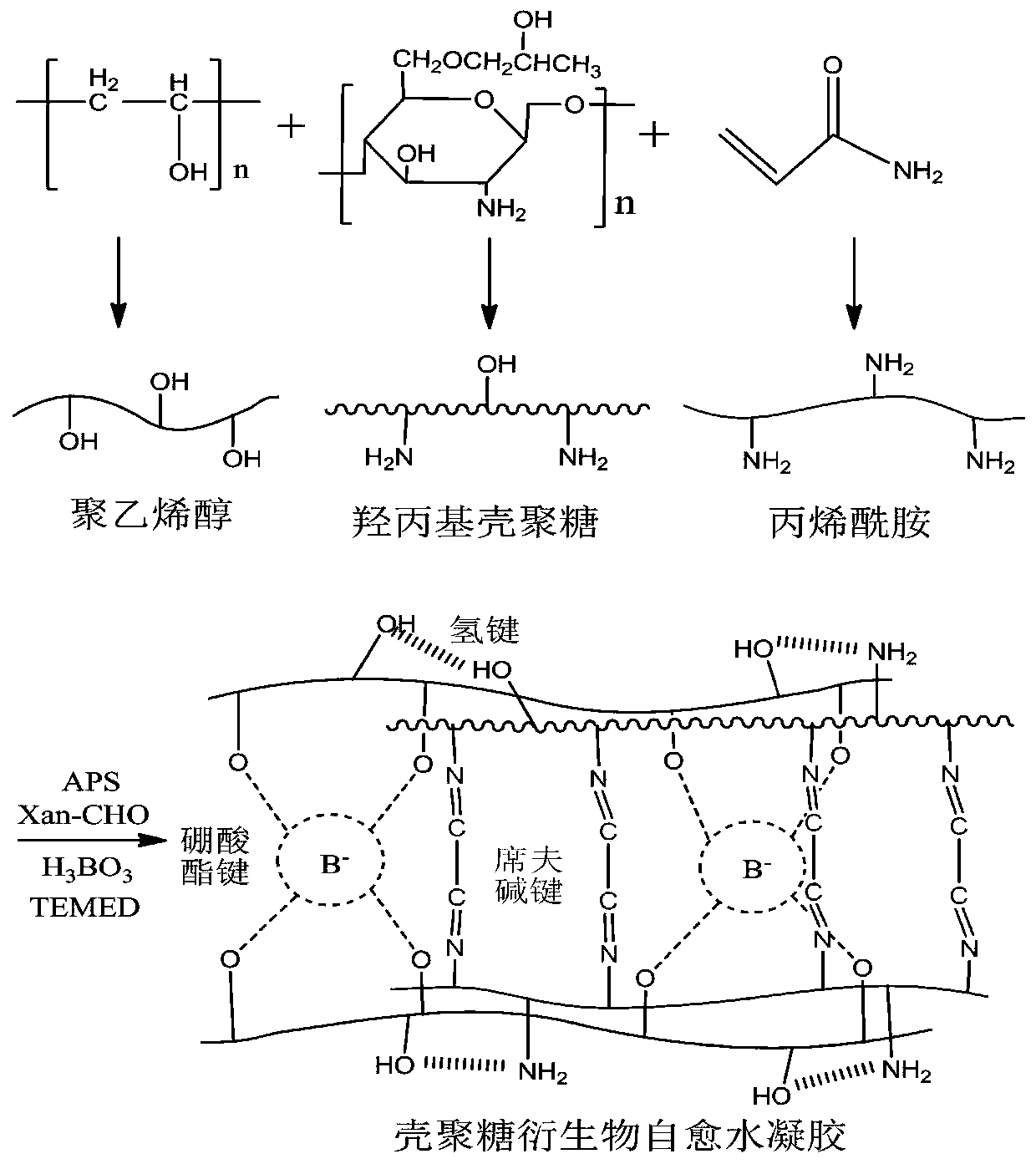

Chitosan derivative self-healing hydrogel and preparation method and application thereof

A chitosan derivative and hydrogel technology, applied in the field of materials, can solve the problems of easily broken hydrogel, low mechanical properties and water absorption, short service life, etc. Good biocompatibility and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

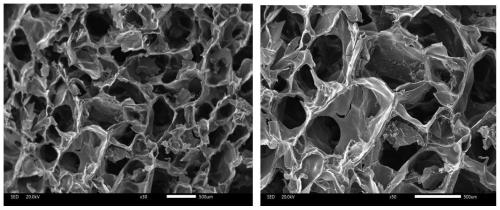

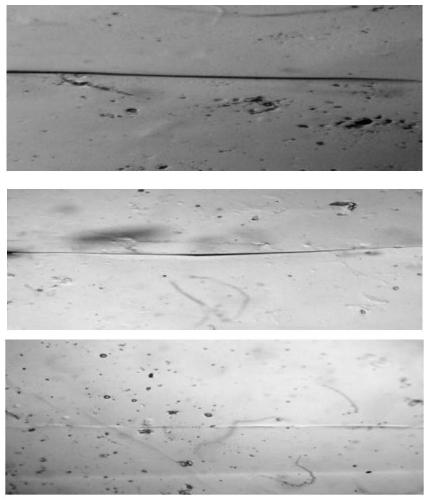

Examples

Embodiment 1

[0032] 1) Selection of raw materials: by weight of each raw material: 35% hydroxypropyl chitosan, 25% polyvinyl alcohol, 40% acrylamide, ammonium persulfate accounts for 13% of the total mass of acrylamide, oxidized sodium alginate and boric acid The mixture accounts for 3% of the total volume of the composite solution, and tetramethylethylenediamine accounts for 0.2% of the total volume of the composite solution, select raw materials and set aside;

[0033] 2) Weigh hydroxypropyl chitosan in a beaker according to the proportioning ratio, add deionized water at 30° C., stir and dissolve evenly, and obtain a hydroxypropyl chitosan solution with a mass volume percentage of 14%;

[0034] 3) Weigh polyvinyl alcohol in a beaker according to the proportion, seal and stir to dissolve evenly at 90°C, obtain a polyvinyl alcohol solution with a mass volume percentage of 9%, add it to the above-mentioned hydroxypropyl chitosan solution at 35°C, and stir Uniformly obtain the polymer mixed...

Embodiment 2

[0040] 1) Selection of raw materials: by weight of each raw material: hydroxypropyl chitosan 40, polyvinyl alcohol 25, acrylamide 35, ammonium persulfate accounts for 12% of the total mass of acrylamide, oxidized sodium alginate and The mixture of boric acid accounts for 3% of the total volume of the composite solution, and tetramethylethylenediamine accounts for 0.2% of the total volume of the composite solution. The raw materials are selected for subsequent use;

[0041] 2) Weighing hydroxypropyl chitosan in a beaker according to the proportioning ratio, adding deionized water at 30°C, stirring and dissolving evenly, to obtain a hydroxypropyl chitosan solution with a mass volume percentage of 16%;

[0042] 3) Weigh polyvinyl alcohol in a beaker according to the proportion, seal and stir to dissolve evenly at 90°C, obtain a polyvinyl alcohol solution with a mass volume percentage of 9%, add it to the above-mentioned hydroxypropyl chitosan solution at 35°C, and stir Uniformly ...

Embodiment 3

[0048] 1) Selection of raw materials: according to the weight parts of each raw material: 40 hydroxypropyl chitosan, 20 polyvinyl alcohol, 40 acrylamide, ammonium persulfate accounts for 13% of the total mass of acrylamide, oxidized sodium alginate and boric acid The mixture accounts for 3% of the total volume of the composite solution, and tetramethylethylenediamine accounts for 0.2% of the total volume of the composite solution, select raw materials and set aside;

[0049] 2) Weighing hydroxypropyl chitosan in a beaker according to the proportioning ratio, adding deionized water at 30°C, stirring and dissolving evenly, to obtain a hydroxypropyl chitosan solution with a mass volume percentage of 16%;

[0050] 3) Weigh polyvinyl alcohol in a beaker according to the proportion, seal and stir at 90°C to dissolve evenly, obtain a polyvinyl alcohol solution with a mass volume percentage of 8%, add it to the above-mentioned hydroxypropyl chitosan solution at 35°C, and stir Uniforml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com