Method for preparing flexible stretchable conductive film with electromagnetic shielding function

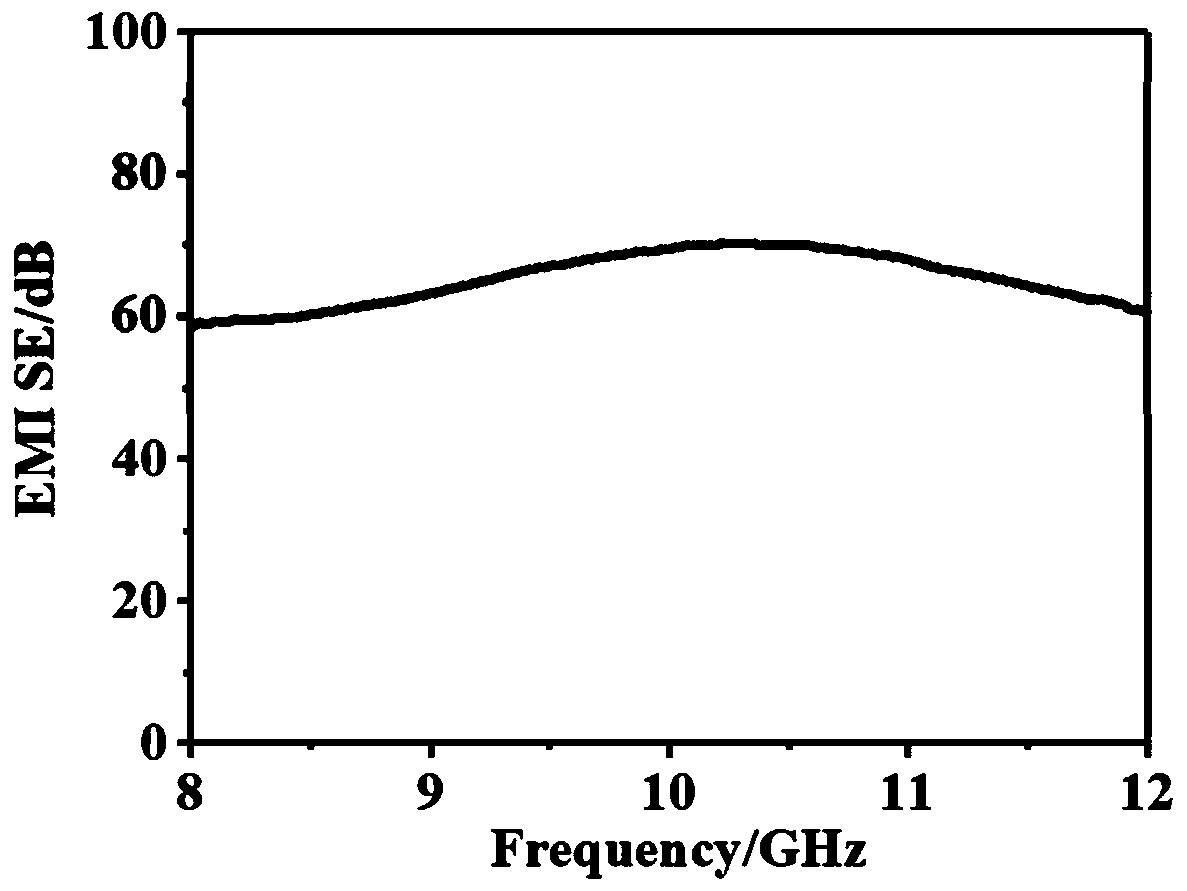

A conductive film, electromagnetic shielding technology, applied in the field of materials, can solve the problems of low shielding efficiency, high density, mutual interference of high-frequency electromagnetic waves, etc., and achieve high electromagnetic interference shielding efficiency, process cost reduction, and good wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

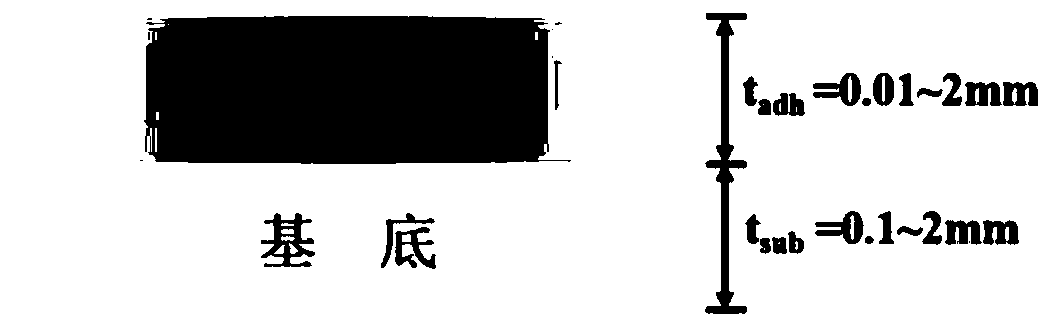

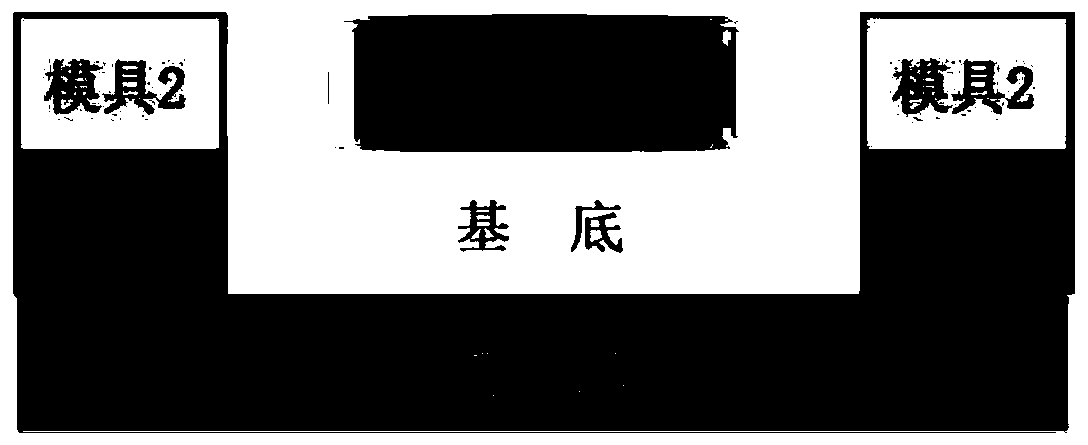

[0036] refer to figure 1 , figure 2 As shown, preparation tools and raw materials: rectangular frame molds of different thicknesses, scrapers, flat bases; polydimethylsiloxane (PDMS), silver nanoparticles, nickel nanoparticles.

[0037] 1) Preparation of fluid polymer materials: select the main agent and curing agent for preparing PDMS, mix them evenly at a mass ratio of 10:1, and remove air bubbles in a vacuum box;

[0038] 2) Preparation of the base: first assemble the mold 1 (thickness 0.5 mm) on the base to form a cuboid groove. Then the fluid state polymer material prepared in step 1) is injected into the tank, and its cross section is shown as figure 2 shown. Then the whole is put into a blast drying oven, and the set temperature and time are respectively 50° C. and 120 min.

[0039]3) Preparation of functional adhesive: take a certain amount of the fluid polymer material prepared in step 1) and pour it into a container, add nickel nanoparticles, then add silver na...

Embodiment 2

[0043] refer to figure 1 , figure 2 As shown, preparation tools and raw materials: rectangular frame molds of different thicknesses, scrapers, flat bases; polydimethylsiloxane (PDMS), silver nanoparticles.

[0044] 1) Preparation of fluid polymer materials: select the main agent and curing agent for preparing PDMS, mix them evenly at a mass ratio of 10:1, and remove air bubbles;

[0045] 2) Preparation of the base: first assemble the mold 1 (thickness 0.5 mm) on the base to form a cuboid groove. Then the fluid state polymer material prepared in step 1) is injected into the tank, and its cross section is shown as figure 2 shown. Then the whole is put into a blast drying oven, and the set temperature and time are respectively 50° C. and 110 min.

[0046] 3) Preparation of functional glue: take a certain amount of the fluid polymer material prepared in step 1) and pour it into a container, add silver nanoparticles, and then mix evenly by means of ultrasonic dispersion and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com