Sustained-released micro-capsule freshly-cut fruit and vegetable preservative and production method and application thereof

A technology of slow-release microcapsules and fruit and vegetable preservatives. It is applied in the fields of fruit and vegetable preservation, application, and food preservation. It can solve the problems of fresh-cut fruits and vegetables such as browning, infection of plant essential oils, and short effective time. Browning speed, effect of good action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

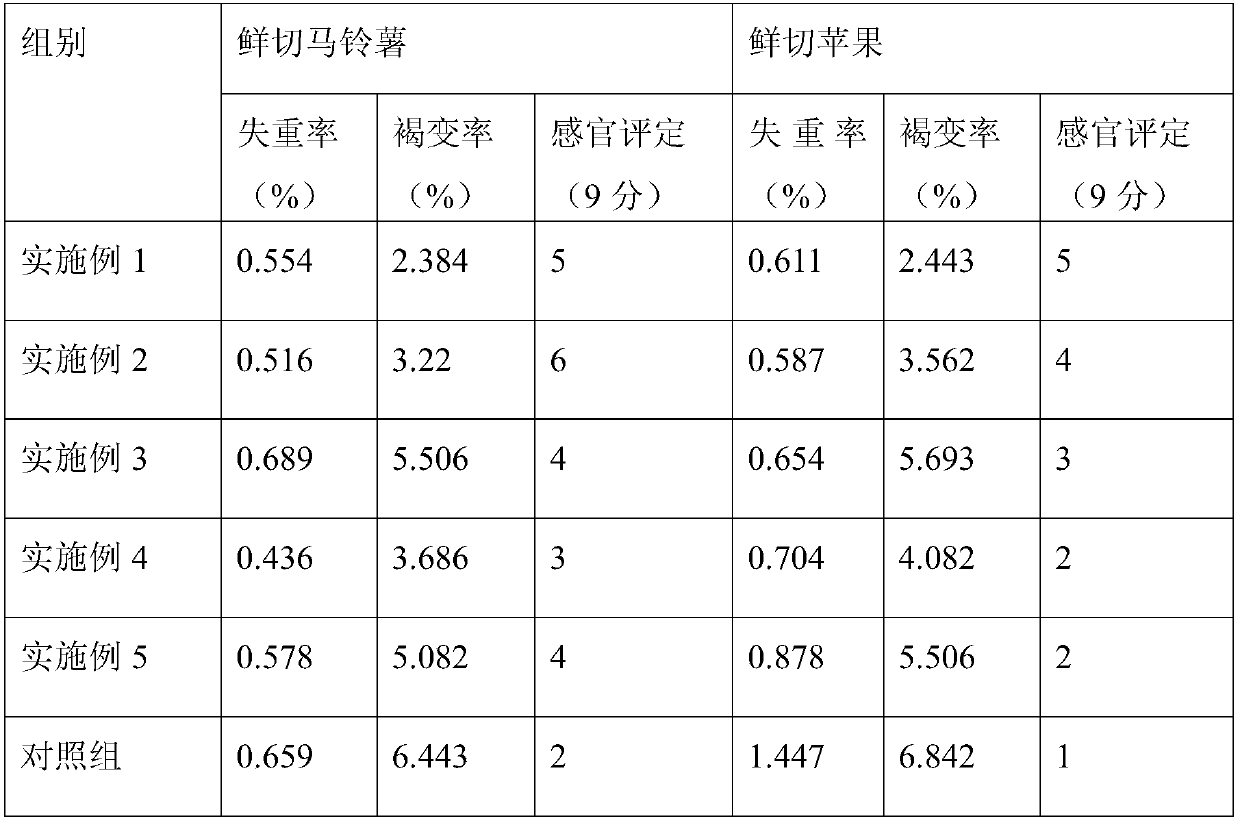

Examples

Embodiment 1

[0022] Mix 2g of chitosan with 60ml of deionized water, heat and stir at 50-60°C to dissolve completely, place at a suitable temperature, add 1g of calcium chloride and stir to dissolve to obtain a chitosan wall material solution; mix 2g of alginic acid Mix sodium with 60ml of deionized water, heat and stir at 50-60°C to completely dissolve sodium alginate wall material solution; mix the above two single wall material solutions at a ratio of 1:1, and then add 2ml of Tween 80 Mix evenly to obtain a composite wall material solution; Cinnamon essential oil, thyme essential oil and oregano essential oil (total volume is 1.2ml) are mixed according to a ratio of 1:1:1 and dissolved in 2ml of absolute ethanol to obtain a composite essential oil, and then Add the compound essential oil to the mixed wall material solution and homogenize for 3 minutes to obtain a sustained-release microcapsule suspension; cool the prepared sustained-release microcapsule suspension to room temperature, an...

Embodiment 2

[0024] Mix 2g of chitosan with 100ml of deionized water, heat and stir at 50-60°C to dissolve it completely, place it at a suitable temperature, add 0.8g of calcium chloride and stir to dissolve to obtain a chitosan wall material solution; mix 2g of seaweed Mix sodium alginate with 100ml deionized water, heat and stir at 50-60°C to dissolve completely to obtain a sodium alginate wall material solution; mix the above two single wall material solutions at a ratio of 1:2, and then add 2ml of Tween Mix at 80°C to make a composite wall material solution; cinnamon essential oil, thyme essential oil and oregano essential oil (total volume is 1.6ml) are dissolved in 2ml of absolute ethanol after mixing according to the ratio of 1:1:2, to obtain a composite essential oil. Then add the compound essential oil to the mixed wall material solution and homogenize for 3 minutes to obtain the sustained-release microcapsule suspension; after cooling the prepared sustained-release microcapsule su...

Embodiment 3

[0026] Mix 1g of chitosan with 60ml of deionized water, heat and stir at 50-60°C to dissolve it completely, place it at a suitable temperature, add 0.8g of calcium chloride and stir to dissolve to obtain a chitosan wall material solution; mix 1g of seaweed Mix sodium alginate with 60ml deionized water, heat and stir at 50-60°C to completely dissolve sodium alginate wall material solution; mix the above two single wall material solutions, then add 1ml Tween 80 and mix well to prepare Obtain a composite wall material solution; dissolve 0.6ml of cinnamon essential oil in 2ml of absolute ethanol to obtain a mixed solution of essential oil, add the mixed solution of essential oil to the mixed wall material solution, and homogenize for 3 minutes to obtain a sustained-release microcapsule suspension; Cool the prepared sustained-release microcapsule suspension to room temperature, then put it into a freezer at 4°C for 12 hours, freeze-dry to obtain the fresh-cut fruit and vegetable sus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com