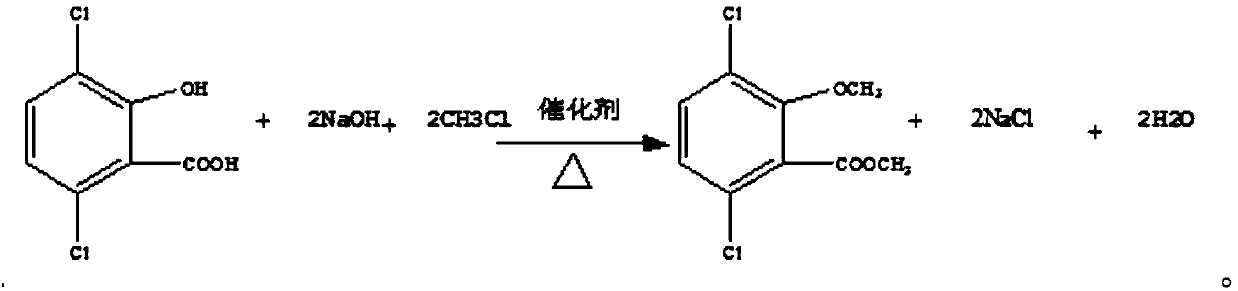

Preparation method of dicamba methyl ester

A technology of dicamba methyl ester and methanol, applied in the field of pesticides, can solve the problems of low purity of dicamba methyl ester, difficult to be widely used, different products, etc., and achieve the effects of improving yield and purity, improving working environment, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Put 1500kg of 3,6-dichlorosalicylic acid, 2300kg of 32% liquid caustic soda, 3000kg of water, 3200kg of 50% methanol and 50kg of tetrabutylammonium bromide into the beating kettle for beating, put it into the etherification kettle after beating, and heat up to 90- Insulate at 95°C, fill with methyl chloride to carry out etherification reaction for 12 hours, after the reaction is completed, transfer the reaction liquid from the etherification tank to the methanol recovery tank to raise the temperature and distill methanol, the temperature rises to 85°C, keep it warm for 1 hour, after the dealcoholization is completed, the methanol is transferred to the methanol storage tank The tank was reused for etherification reaction, and after dealcoholization, the liquid was left to stand for 60 minutes to separate layers, and the water phase was transferred to multi-effect evaporation for treatment. The oil phase is transferred to the still. Turn on the vacuum pump, pump the negat...

Embodiment 2

[0042] Put 1502kg of 3,6-dichlorosalicylic acid, 2302kg of 32% liquid caustic soda, 3005kg of water, 3202kg of 50% methanol and 50kg of benzyltriethylammonium chloride into the beating kettle for beating, put it into the etherification kettle after beating, and heat up to 90 Insulate at -95°C, fill with methyl chloride and carry out etherification reaction for 11 hours. After the reaction is completed, transfer the reaction liquid from the etherification kettle to the methanol recovery kettle to heat up and distill the methanol. The temperature rises to 90°C and keep the temperature for 1 hour. The storage tank was reused for etherification reaction, and after dealcoholization, the liquid was left to stand for 80 minutes to separate layers, and the water phase was transferred to multi-effect evaporation for treatment. The oil phase is transferred to the rectifying kettle. Turn on the vacuum pump, pump the negative pressure to -0.090Mpa, raise the temperature to 200°C and begin...

Embodiment 3

[0044] Put 1502kg of 3,6-dichlorosalicylic acid, 2303kg of 32% liquid caustic soda, 3005kg of water, 3202kg of 50% methanol and 50kg of tetrabutylammonium chloride into the beating kettle for beating, put into the etherification kettle after beating, and heat up to 90-95 Keep warm at ℃, fill with methyl chloride and carry out etherification reaction for 12 hours. After the reaction is completed, transfer the reaction liquid from the etherification tank to the methanol recovery tank to raise the temperature and distill the methanol. The etherification reaction was used again, and after the dealcoholization, the liquid was left to stand for 80 minutes to separate layers, and the water phase was transferred to multi-effect evaporation for treatment. The oil phase is transferred to a molecular still. Turn on the vacuum pump, pump the negative pressure to -0.090Mpa, raise the temperature to 200°C and begin to produce distillates, heat-preserved distillation, the gas phase is conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com