Iron-manganese-modified algae adsorbent and preparation method thereof

The technology of adsorbent and algae is applied in the field of iron-manganese modified algae adsorbent and its preparation, which can solve the problems of large resource consumption and low adsorption capacity of algae, and achieve the effects of low price, no secondary pollution and wide source.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention proposes a preparation method of an iron-manganese modified algae adsorbent, comprising the following steps:

[0027] a) Add permanganate to the algae outbreak water body, mix to obtain solution 1;

[0028] b) adding ferrous salt to solution 1 obtained in step a), mixing, and standing to obtain solution 2;

[0029] c) centrifuging the solution two obtained in step b), removing the supernatant, and drying the obtained precipitate;

[0030] d) washing the dried precipitate in step c) with alkali, centrifuging, washing with ultrapure water to neutrality, then drying and grinding the treated precipitate to obtain the iron-manganese modified algae adsorbent.

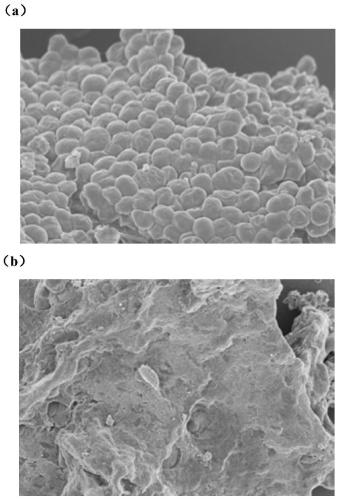

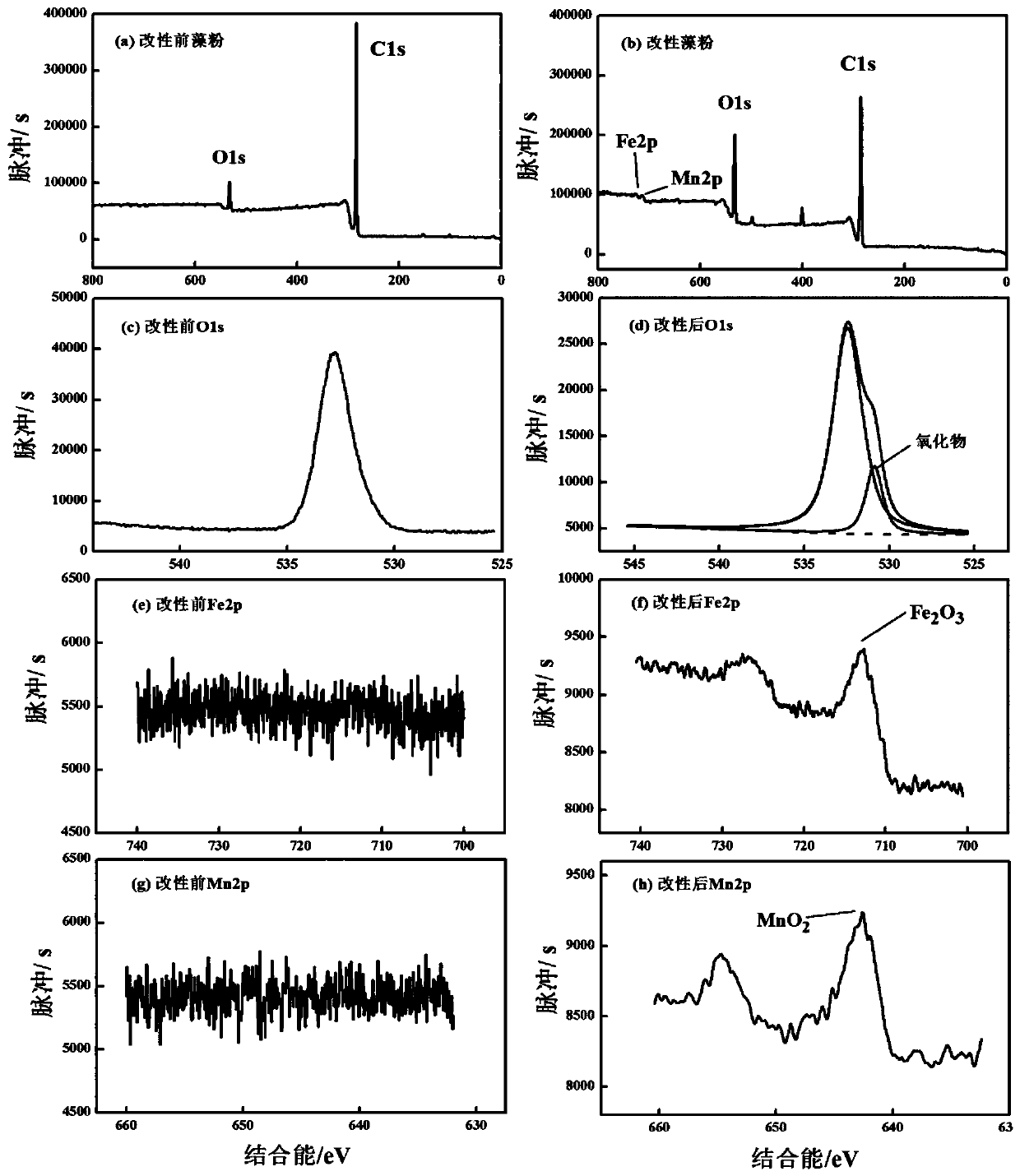

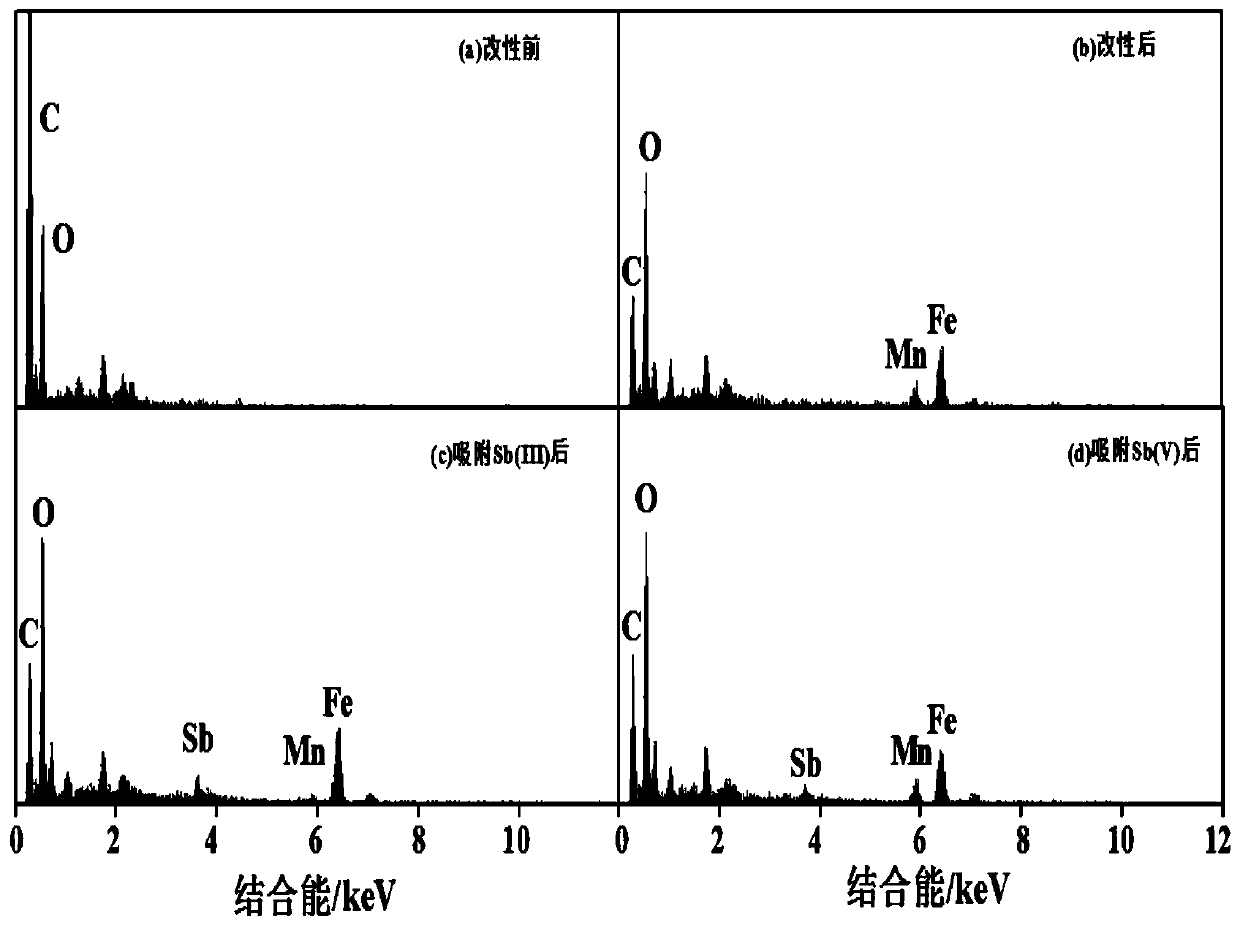

[0031] Algae is an excellent adsorbent, because its cell wall contains a large number of carboxyl groups, hydroxyl groups and amino groups, and heavy metals can be removed through surface complexation. However, the adsorption capacity of algae is low compared with other adsorbe...

Embodiment 1

[0049] Example 1 : Preparation of Fe-Mn Modified Algae Adsorbent

[0050] a) Eutrophication pollution occurs in the water source of a water plant, and algae blooms, and the concentration of algae cells in the sample reaches 10 9 Each / L of the algae outbreak water body, add potassium permanganate to the algae outbreak water body until its concentration in the system is 12 μmol L -1 , stirred at 220rpm for 2min to obtain solution 1;

[0051] b) Add FeSO to solution one obtained in step a) 4 ·7H 2 O until its concentration in the system is 36 μmol L -1 , stirred at 40rpm for 60min, and left to age for 4h to obtain solution 2;

[0052] c) The solution 2 obtained in step b) was centrifuged at 4500rpm for 10min, and after removing the supernatant, the precipitate was freeze-dried for 48h;

[0053] d) Add a sufficient concentration of 0.1mol L to the dried precipitate in step c). -1 The NaOH solution was stirred for 6 hours by a rotating agitator, and then centrifuged after a...

Embodiment 2

[0054] Example 2 : Preparation of Fe-Mn Modified Algae Adsorbent

[0055] a) Eutrophication pollution occurred in the water source of a water plant, algae broke out, and the concentration of algae-containing cells reached 10 8 Each / L of the algae outbreak water body, add sodium permanganate to the algae outbreak water body until its concentration in the system is 10 μmol L -1 , stirred at 200rpm for 2min to obtain solution 1;

[0056] b) Add ferrous nitrate to solution one obtained in step a) until its concentration in the system is 30 μmol L -1 , stirred at 40rpm for 50min, and left to age for 4h to obtain solution 2;

[0057] c) The solution 2 obtained in step b) was centrifuged at 4000rpm for 8min, and after removing the supernatant, the precipitate was freeze-dried for 45h;

[0058] d) Add a sufficient concentration of 0.08mol L to the dried precipitate in step c). -1 The NaOH solution was stirred for 6 hours by a rotating agitator, and then centrifuged after alkalin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com