A laser cleaning and polishing composite processing method for carbon steel surface

A laser cleaning and composite processing technology, applied in cleaning methods and utensils, laser welding equipment, metal processing equipment, etc., can solve the problem that the surface performance and production efficiency are not achieved, the surface roughness is not optimal, and the topographic surface is not obtained. and other problems, to achieve the effect of facilitating automated production, increasing surface defects, and avoiding heat superposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

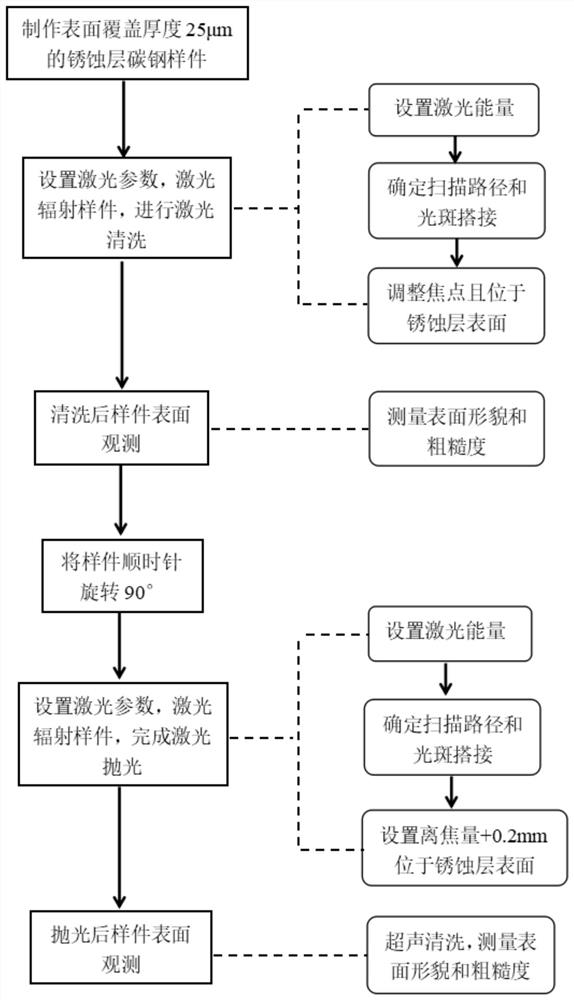

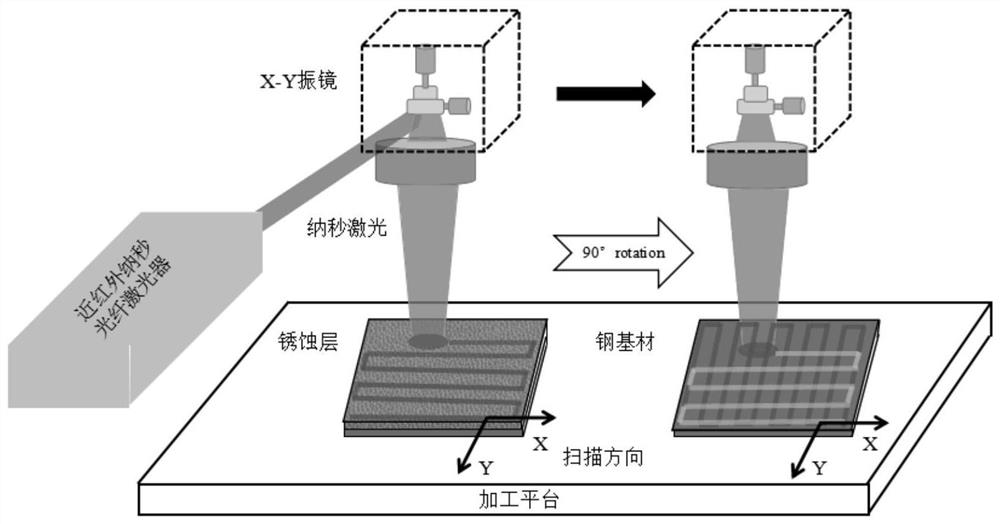

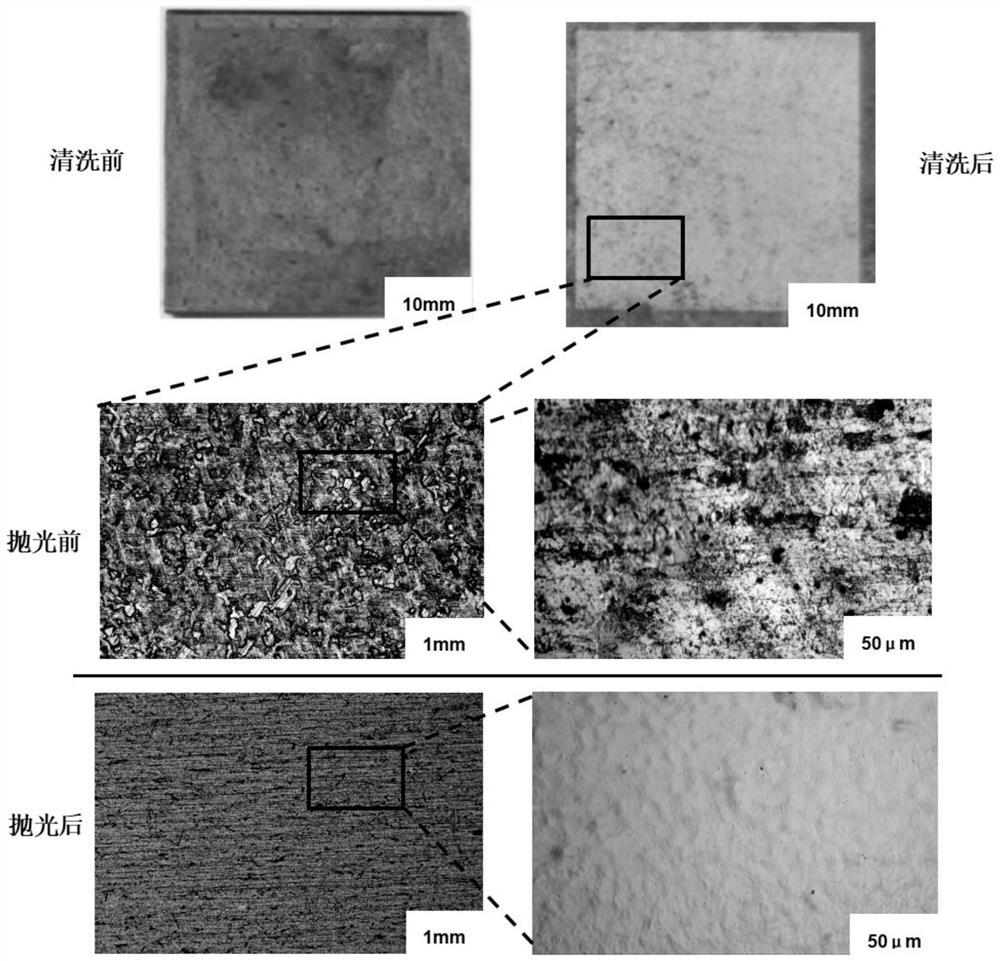

[0036]Such asfigure 1 ,figure 2 withimage 3 As shown, the present embodiment discloses a laser cleaning and polishing composite processing method for the surface of the carbon steel, which mainly includes the specifically steps:

[0037]Step S1: Preparation of carbon steel samples that completely cover the corrosion layer, the copolymerized microscope measures its corrosive layer thickness, surface profile gauge measurement surface roughness, and positioned, placed on nanosecond pulsed laser processing X / Y / Z workbench .

[0038]Step S2: Start the nancy pulse laser processing system and regulate the output wavelength λ, the phototraum waist radius ω, the maximum output power P, the pulse width τ, the repetition frequency f, the scanning speed V, and the process parameters such as the output wavelength λ, the phototrammolle width τ, the repetition frequency F, the scanning speed V. Different energy density and spot overlap ratios are possible to meet the energy density required for lase...

Embodiment 2

[0056]Such asFigure 1 to 3As shown, the present embodiment discloses a laser cleaning and laser polishing composite method for the surface of the carbon steel material.figure 1 As shown, mainly includes the following steps:

[0057](1) Preparation of a carbon steel sample having a thickness having a thickness of the rust layer, the copolymerization microscope measures its rust layer thickness of 25 μm, the surface profile meter measures the surface roughness SA of 3.3 μm, positioned, placed in nanosecond pulse Laser processing X / Y / Z workbench;

[0058](2) Start the laser processing system, the laser is a near-infrared nanosecond fiber laser. The laser processing system output wavelength λ is 1064 nm, the phototraum waist radius ω = 20 μm; the maximum output power P is 20W, the pulse width τ = 4 ~ 200 ns, the repetition frequency f = 0 ~ 2000mm / s process Parameters can be adjusted. Different energy density and spot overlap ratios are achieved by the regulation of the above process pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com