Green waterproof concrete and preparation method thereof

A waterproof concrete and green technology, applied in the field of concrete, can solve the problems of concrete waterproof and frost resistance deviation, limit the application expansion of concrete, etc., achieve the effect of improving frost resistance, improving waterproof and frost resistance performance, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

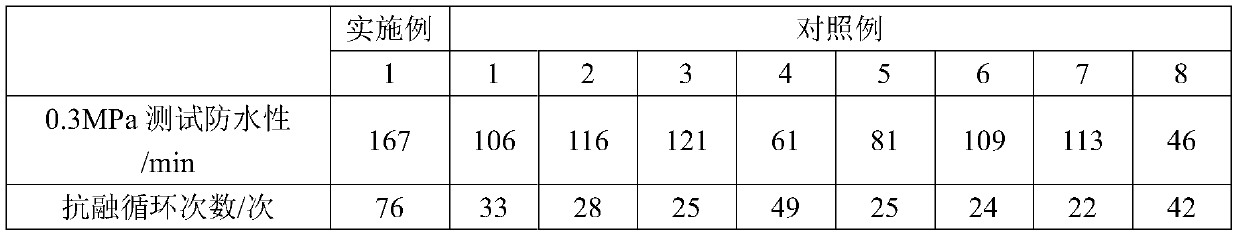

Examples

Embodiment 1

[0021] A kind of green waterproof concrete, its preparation method comprises the following steps:

[0022] (1) Add 25 parts of iron sludge, 18.2 parts of waste polyacrylamide flocculant, 15.1 parts of waste polyaluminum chloride flocculant and 3.7 parts of carboxymethyl cellulose into the high-speed mixer, and maintain the mixing temperature of the system at 80°C After reacting at low temperature for 30 minutes, the product was heat-treated at 100°C for 1 hour, at 200°C for 1 hour, at 300°C for 1 hour, at 500°C for 2 hours, at 700°C for 2 hours, at 900°C for 2 hours, at 1000°C for 3 hours, and pulverized to obtain modified iron slime;

[0023] (2), 23 parts of isooctyl acrylate, 19 parts of butyl acrylate, 10.1 parts of acrylic acid, 16.5 parts of low-viscosity aliphatic epoxy acrylate, 0.4 part of 819 photoinitiator, 13.7 parts of polyethylene glycol (200) Add methacrylate and 5.2 parts of SE-10 emulsifier to the reaction kettle, the stirring speed is 100r / min, the reaction t...

Embodiment 2

[0028] A kind of green waterproof concrete, its preparation method comprises the following steps:

[0029] (1) Add 25 parts of iron sludge, 15 parts of waste polyacrylamide flocculant, 12 parts of waste polyaluminum chloride flocculant and 2 parts of carboxymethyl cellulose into the high-speed mixer, and maintain the mixing temperature of the system at 80°C After reacting at low temperature for 30 minutes, the product was heat-treated at 100°C for 1 hour, at 200°C for 1 hour, at 300°C for 1 hour, at 500°C for 2 hours, at 700°C for 2 hours, at 900°C for 2 hours, at 1000°C for 3 hours, and pulverized to obtain modified iron slime;

[0030] (2), 23 parts of isooctyl acrylate, 16 parts of butyl acrylate, 6 parts of acrylic acid, 13 parts of low-viscosity aliphatic epoxy acrylate, 0.3 part of 819 photoinitiator, 7 parts of polyethylene glycol (200) Add methacrylate and 3 parts of SE-10 emulsifier to the reaction kettle, stir at 100r / min, and react at 35°C for 30min. The product is ...

Embodiment 3

[0035] A kind of green waterproof concrete, its preparation method comprises the following steps:

[0036] (1) Add 25 parts of iron sludge, 21 parts of waste polyacrylamide flocculant, 19 parts of waste polyaluminum chloride flocculant and 6 parts of carboxymethyl cellulose into the high-speed mixer, and maintain the mixing temperature of the system at 80°C After reacting at low temperature for 30 minutes, the product was heat-treated at 100°C for 1 hour, at 200°C for 1 hour, at 300°C for 1 hour, at 500°C for 2 hours, at 700°C for 2 hours, at 900°C for 2 hours, at 1000°C for 3 hours, and pulverized to obtain modified iron slime;

[0037] (2), 23 parts of isooctyl acrylate, 25 parts of butyl acrylate, 14 parts of acrylic acid, 19 parts of low-viscosity aliphatic epoxy acrylate, 1 part of 819 photoinitiator, 18 parts of polyethylene glycol (200) Add methacrylate and 7 parts of SE-10 emulsifier to the reaction kettle, stir at 100r / min, and react at 35°C for 30 minutes. The produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com