Rubber aggregate special-type concrete for airfield pavement in high and cold area of plateau

A rubber aggregate, technology in alpine regions, applied in the field of building materials, can solve the problems that ordinary concrete is difficult to meet the use requirements, frequent pavement diseases, and difficult to repair, and achieves outstanding technical advantages, economic benefits, and outstanding wear resistance. and fatigue resistance, overall cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

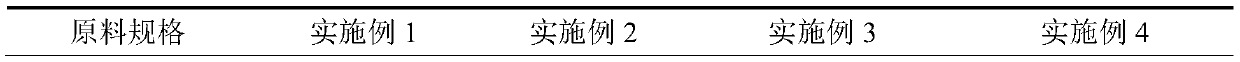

[0023] This embodiment provides a kind of rubber aggregate special concrete for airport pavement in plateau alpine region, and its raw material ratio and specific parameters are: cement 405kg / m 3 , Mineral auxiliary material 50kg / m 3 , fine aggregate 680kg / m 3 , coarse aggregate 1210kg / m 3 , rubber aggregate 110kg / m 3 , active magnesium oxide 10.2kg / m 3 , water reducer 8.7kg / m 3 , water 163kg / m 3 .

[0024] Specifically, the cement is Portland cement with a strength grade of 52.5;

[0025] The mineral auxiliary material is Class I fly ash;

[0026] The fine aggregate is machine-made sand, the fineness modulus of machine-made sand is 2.0-3.1, and the content of machine-made sand and stone powder is not more than 8%;

[0027] Coarse aggregate is crushed stone with a particle size range of 5mm to 37.5mm, wherein the coarse aggregate includes large stones and small stones, the particle size of large stones is 20mm to 37.5mm, and the mass percentage of large stones to the a...

Embodiment 2

[0031] This embodiment provides a kind of rubber aggregate special concrete for airport pavement in plateau alpine region, and its raw material ratio and specific parameters are: cement 380kg / m 3 , Mineral auxiliary material 80kg / m 3 , fine aggregate 650kg / m 3 , coarse aggregate 1210kg / m 3 , rubber aggregate 100kg / m 3 , active magnesium oxide 13kg / m 3 , water reducer 7.8kg / m 3 , water 185kg / m 3 .

[0032] Specifically, the cement is Portland cement with a strength grade of 42.5;

[0033] Mineral auxiliary material is slag;

[0034] The fine aggregate is river sand, the fineness modulus of the river sand is 2.0-3.1, and the mud content of the river sand is not more than 2%;

[0035] Coarse aggregate is crushed stone with a particle size range of 5mm to 37.5mm, wherein the coarse aggregate includes large stones and small stones, the particle size of large stones is 20mm to 37.5mm, and the mass percentage of large stones to the amount of coarse aggregate is 40% to 60%. ,...

Embodiment 3

[0039] This embodiment provides a kind of rubber aggregate special concrete for airport pavement in plateau alpine region, and its raw material ratio and specific parameters are: cement 320kg / m 3 , Mineral auxiliary materials 142kg / m 3 , fine aggregate 650kg / m 3 , coarse aggregate 1210kg / m 3 , rubber aggregate 80kg / m 3 , active magnesium oxide 14kg / m 3 , superplasticizer 10.5kg / m 3 , water 152kg / m 3 .

[0040] Specifically, the cement is Portland cement with a strength grade of 42.5;

[0041] Mineral auxiliary material is a mixture of silica fume and fly ash, of which silica fume is 42kg / m 3 , fly ash 100kg / m 3 ;

[0042] The fine aggregate is a mixture of natural sand and machine-made sand, of which the fineness modulus of the mixed sand is 2.8, and the mud content of natural sand is not higher than 2%, and the content of machine-made sand and stone powder is not more than 8%;

[0043] Coarse aggregate is crushed stone with a particle size range of 5mm to 37.5mm, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap