Preparation method of modified loess-based ceramsite for treating rainwater

A modification and loess technology, applied in clay products, ceramic products, sustainable biological treatment and other directions, can solve the problems of polluted water and soil environment, coal gangue occupying large land, air pollution, etc. The effect of poor infiltration performance and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

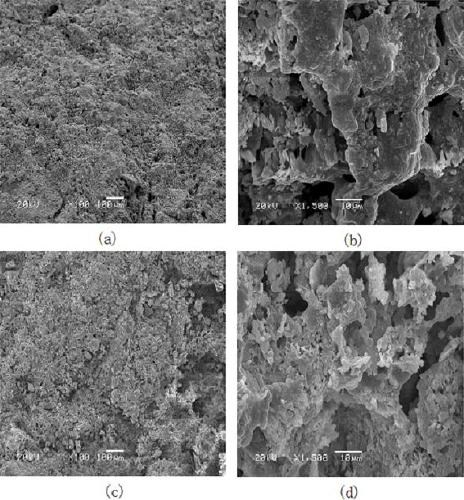

[0024] Example 1 A method for preparing modified loess-based ceramsite for treating rainwater, the method refers to: first, 2 kg of modified loess, 1 kg of modified coal gangue, 0.45 kg of bentonite, 0.30 kg of sodium silicate, and 0.15 kg of calcium carbonate After mixing evenly, add water and stir evenly to make mud. The mud is made into pellets with a particle size of 5~10mm by a pelletizing machine; then the shaped pellets are dried at 105°C for 2~4 hours, and then fired in a muffle furnace. After the furnace is naturally cooled, take it out to obtain loess-based ceramsite.

Embodiment 2

[0025] Example 2 A method for preparing modified loess-based ceramsite for treating rainwater. The method refers to: first mix 1 kg of modified loess, 1 kg of modified coal gangue, 0.40 kg of bentonite, and 0.50 kg of sodium silicate, and then add water and stir Uniformly made mud material, the mud material is made of pellets with a particle size of 5~10mm by a pelletizing machine; then the shaped pellets are dried at 105°C for 2~4 hours, and then fired in a muffle furnace, and the furnace is naturally Take it out after cooling to get loess-based ceramsite.

Embodiment 3

[0026] Example 3 A method for preparing modified loess-based ceramsite for treating rainwater. The method refers to: firstly, 1.5 kg of modified loess, 1 kg of modified coal gangue, 0.45 kg of bentonite, 0.5 kg of sodium silicate, and 0.0625 kg of carbonic acid After the calcium is mixed evenly, add water and stir evenly to make mud. The mud is made of pellets with a particle size of 5~10mm by a pelletizing machine; then the shaped pellets are dried at 105°C for 2~4 hours, and then processed in a muffle furnace. Fire it, and take it out after the furnace cools down naturally to get the loess-based ceramsite.

[0027] In the above-mentioned Examples 1-3, the modified loess refers to the obtained loess in Lanzhou area from which impurities have been removed from the soil, passed through a 60-mesh sieve, and dried at 105° C. for 2 hours.

[0028] Modified coal gangue is obtained by crushing coal gangue through a 60-mesh sieve and drying at 105°C for 2 hours.

[0029] The firing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com